Drill end actuator

A technology of end effector and optical axis, which is applied in the direction of drilling/drilling equipment, parts of boring machine/drilling machine, metal processing equipment, etc., and can solve problems such as difficulty in ensuring consistency in accuracy and quality, boring process, and heavy workload. , to achieve the effect of optimizing tool structure and cutting parameters, compact overall structure and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

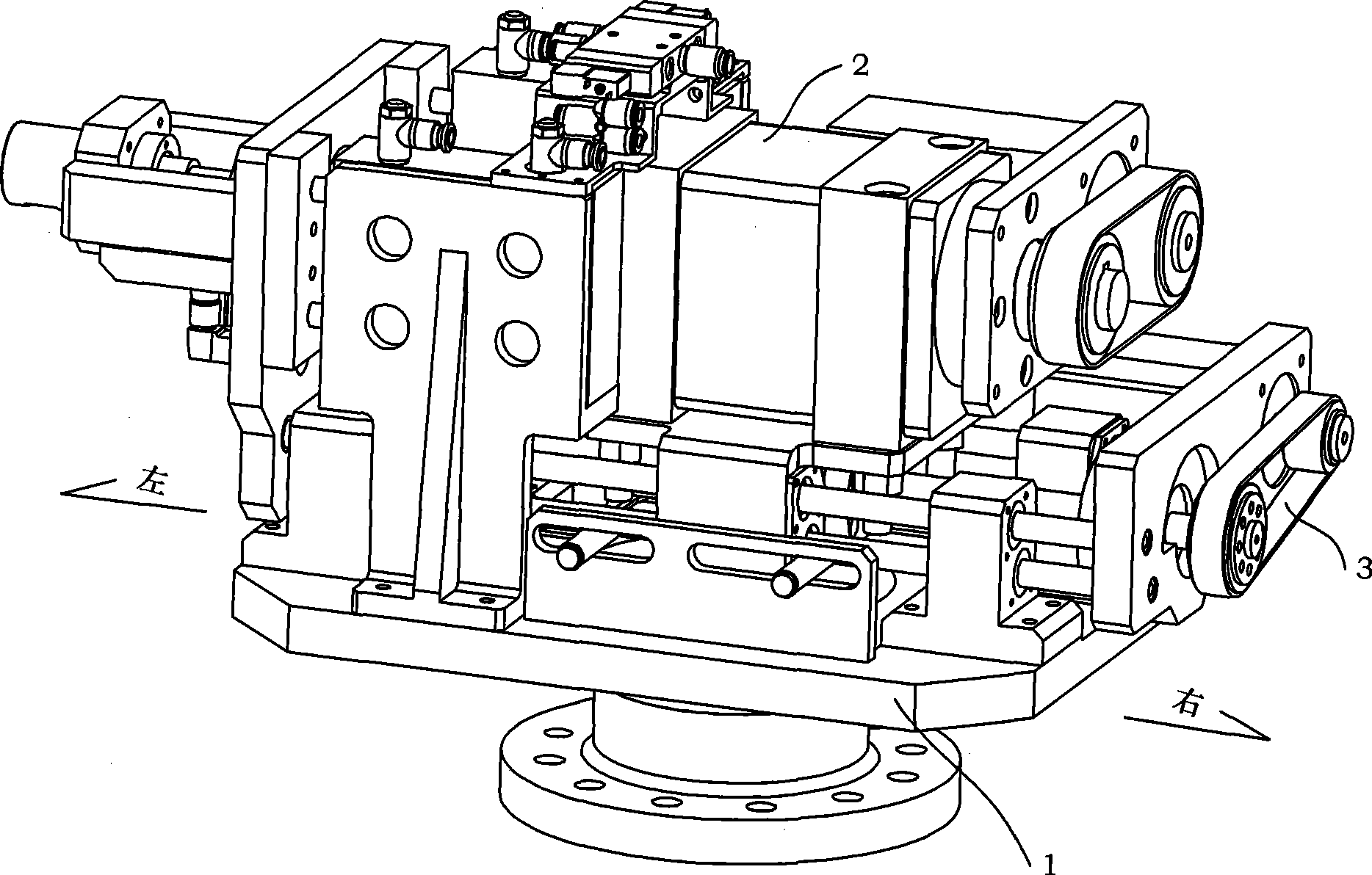

[0024] see figure 1 As shown, a drilling end effector for an industrial robot of the present invention includes a support unit 1, a spindle unit 2 and a feed unit 3; the rear plate 305 of the feed unit 3 is connected with The four optical axes (A optical axis 121 , B optical axis 122 , C optical axis 123 , and D optical axis 124 ) of the support unit 1 and the spindle unit 2 are installed on the spindle head support 102 of the support unit 1 .

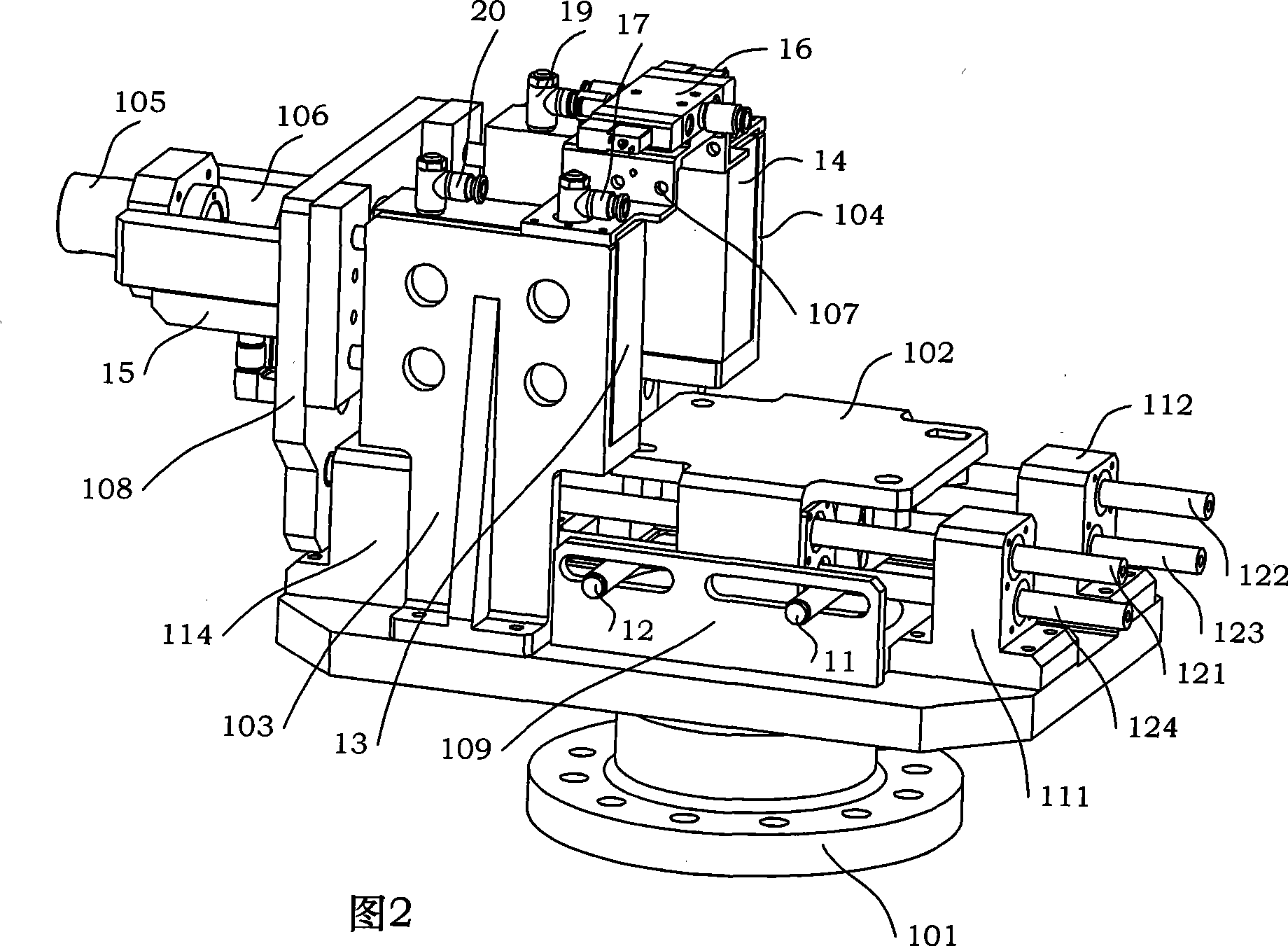

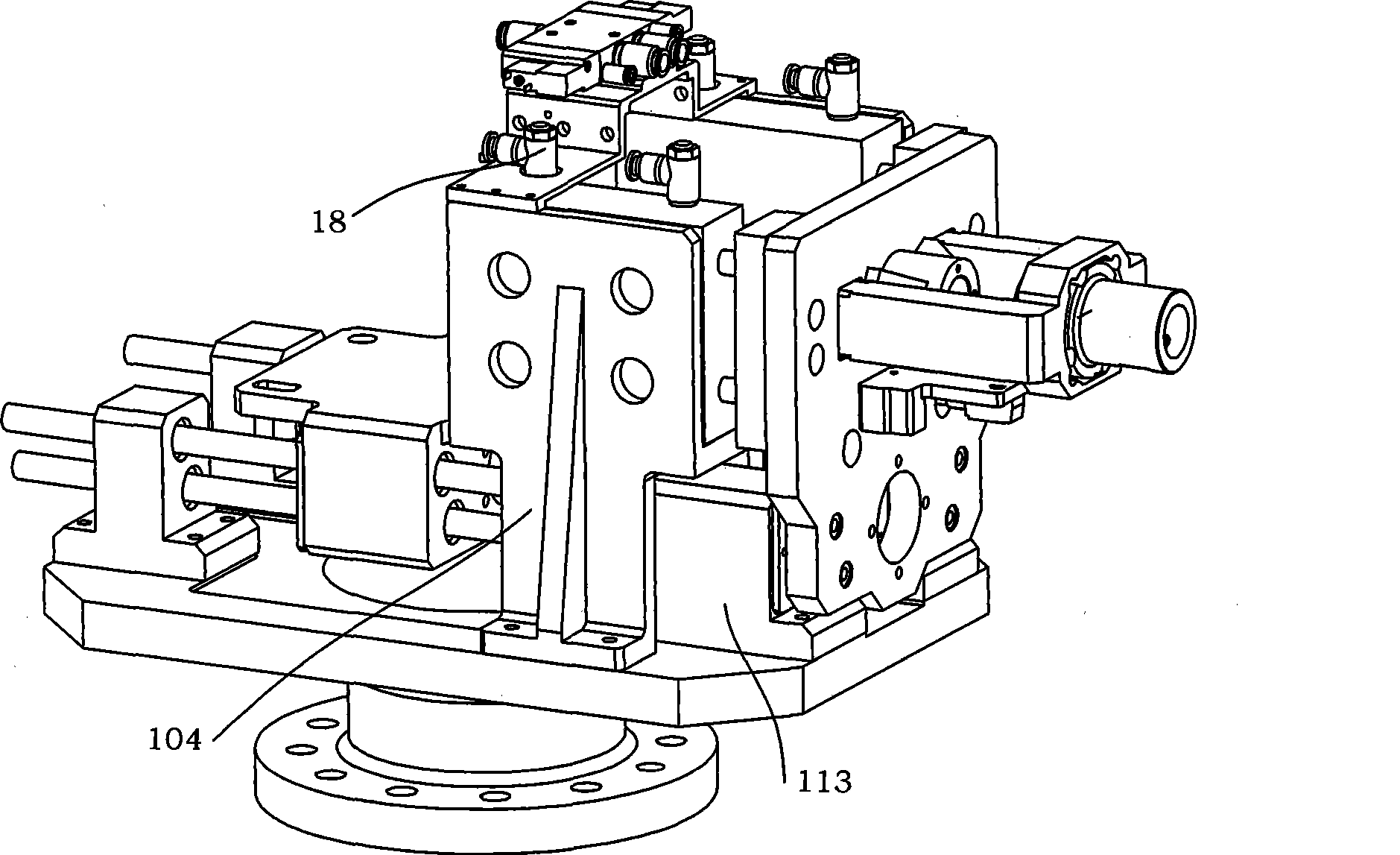

[0025] See Figure 2, Figure 2A , as shown in Figure 2B, the support unit 1 includes a base 101, four shaft seats (A shaft seat 111, B shaft seat 112, C shaft seat 113, D shaft seat 114), four optical axes (A optical axis 121 , B optical axis 122, C optical axis 123, D optical axis 124), two cylinder supports (A cylinder support 103, B cylinder support 104), spindle head support 102, A connecting plate 107, front pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com