Ultra length and width real wood floor manufacture method

A technology of solid wood flooring and manufacturing methods, applied in the direction of humidity control wood, manufacturing tools, wood processing utensils, etc., to achieve the effects of eliminating or controlling deformation problems, overcoming deformation, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

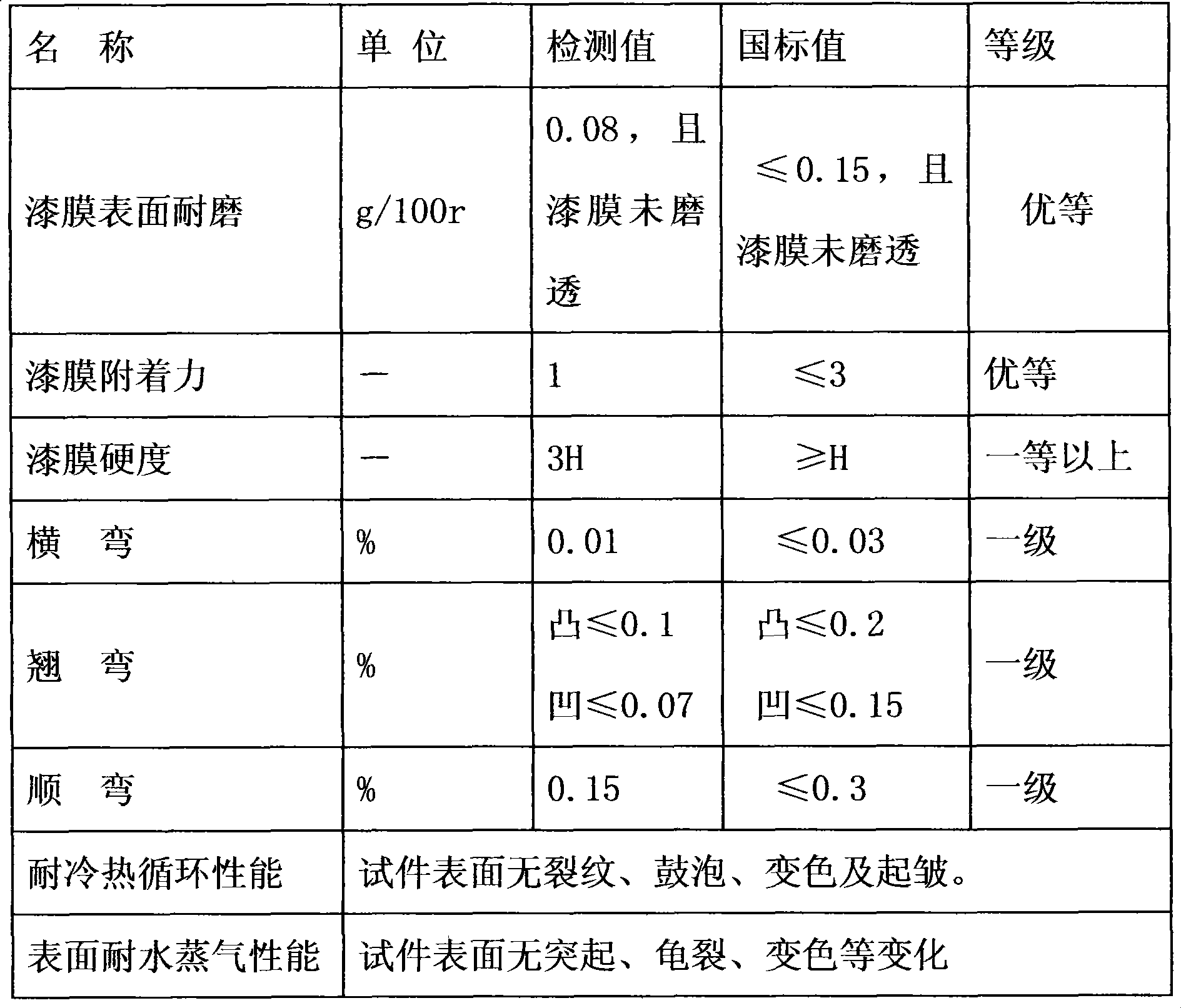

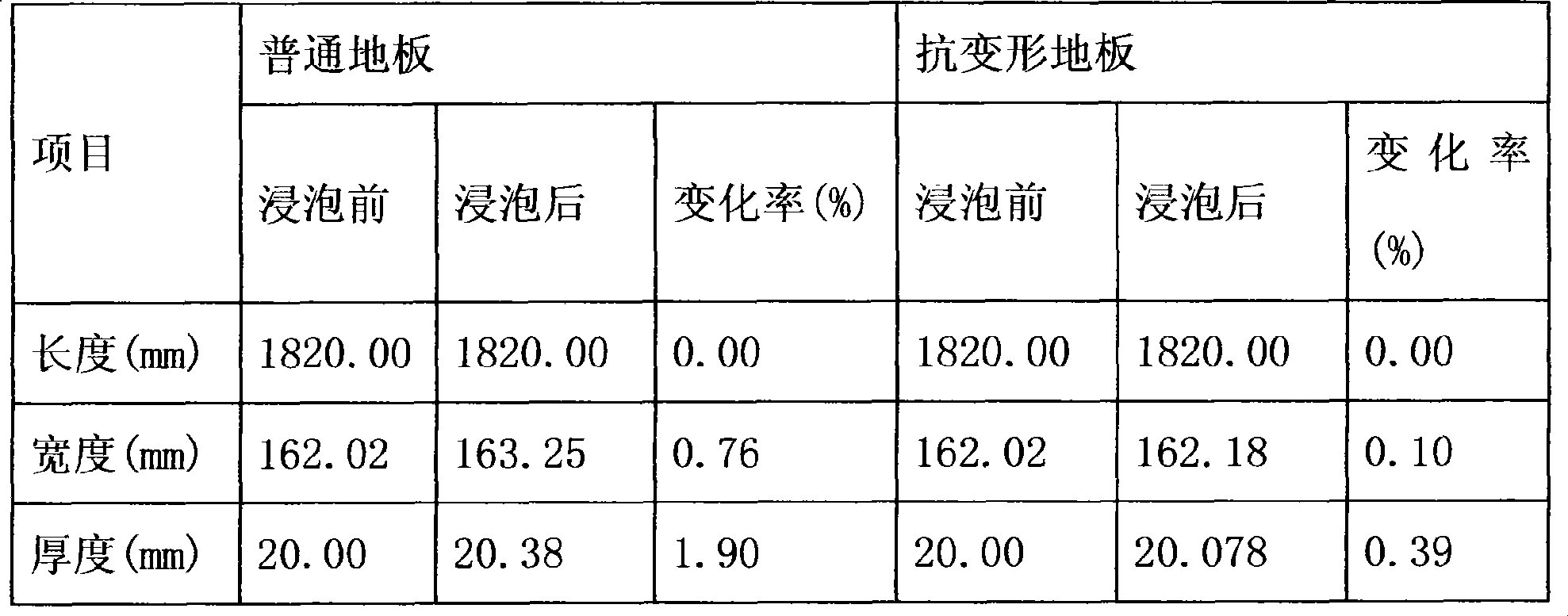

Examples

Embodiment 1

[0028] This example first carries out step one, material selection, adopts balsam pigeonpea (red sandalwood) tree species as blank, and its basic density is 0.90g / cm 3 , air dry density 0.95g / cm 3 . The specifications of the finished floor are: length × width × thickness = 1820 × 162 × 20mm, and the average initial moisture content is 39.17%.

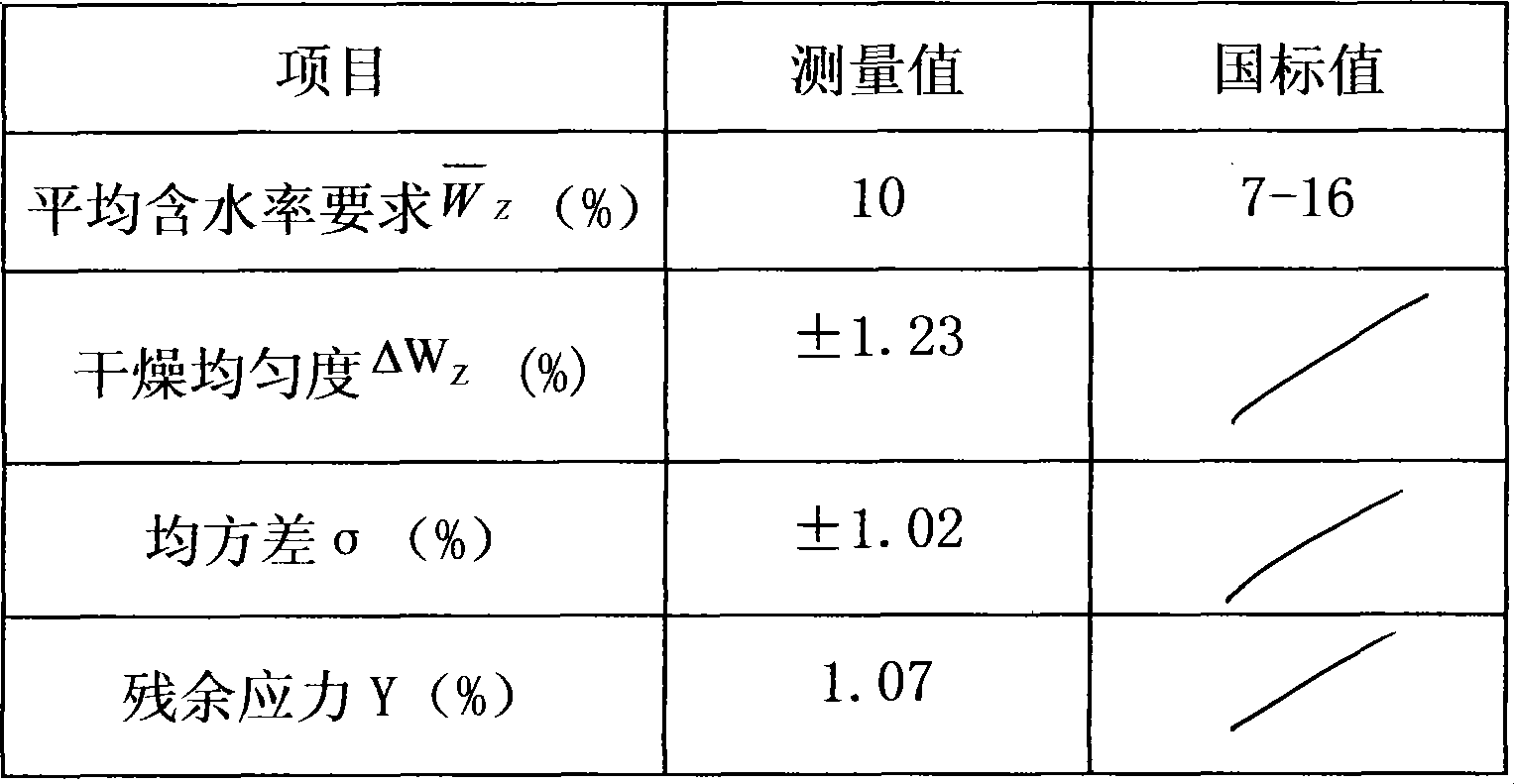

[0029] 2. Drying

[0030]The high-efficiency and energy-saving steam heating drying kiln is used for low-temperature intermittent drying process. Dry and control the moisture content of the balsamic pea floor blank, so that the final moisture content required by the floor blank is 10-14%; during the heating process, when the temperature difference between the dry bulb and the wet bulb is within 2°C, no spray steaming is performed, and when the dry bulb and the wet bulb temperature difference are within 2°C If the temperature difference is beyond 2°C, spray steaming is required. As shown in Table 1, Table 1 is the standard table of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Air dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com