Method for producing low-sulfur gasoline from catalytically cracked gasoline

A technology for catalytically cracking gasoline and gasoline, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of low octane number loss, poor flexibility, and cannot be solved at the same time, and achieves high octane number, Qualified effect of thiol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

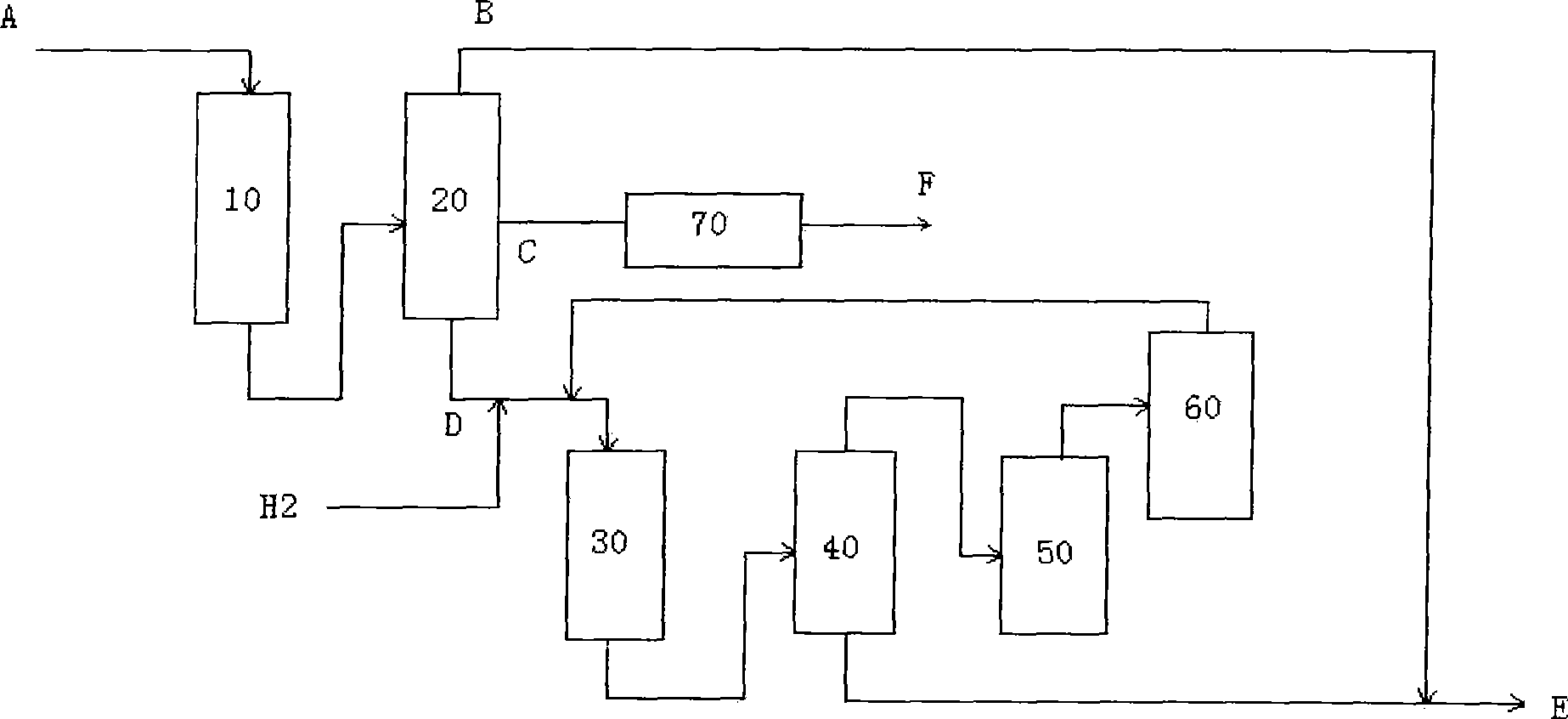

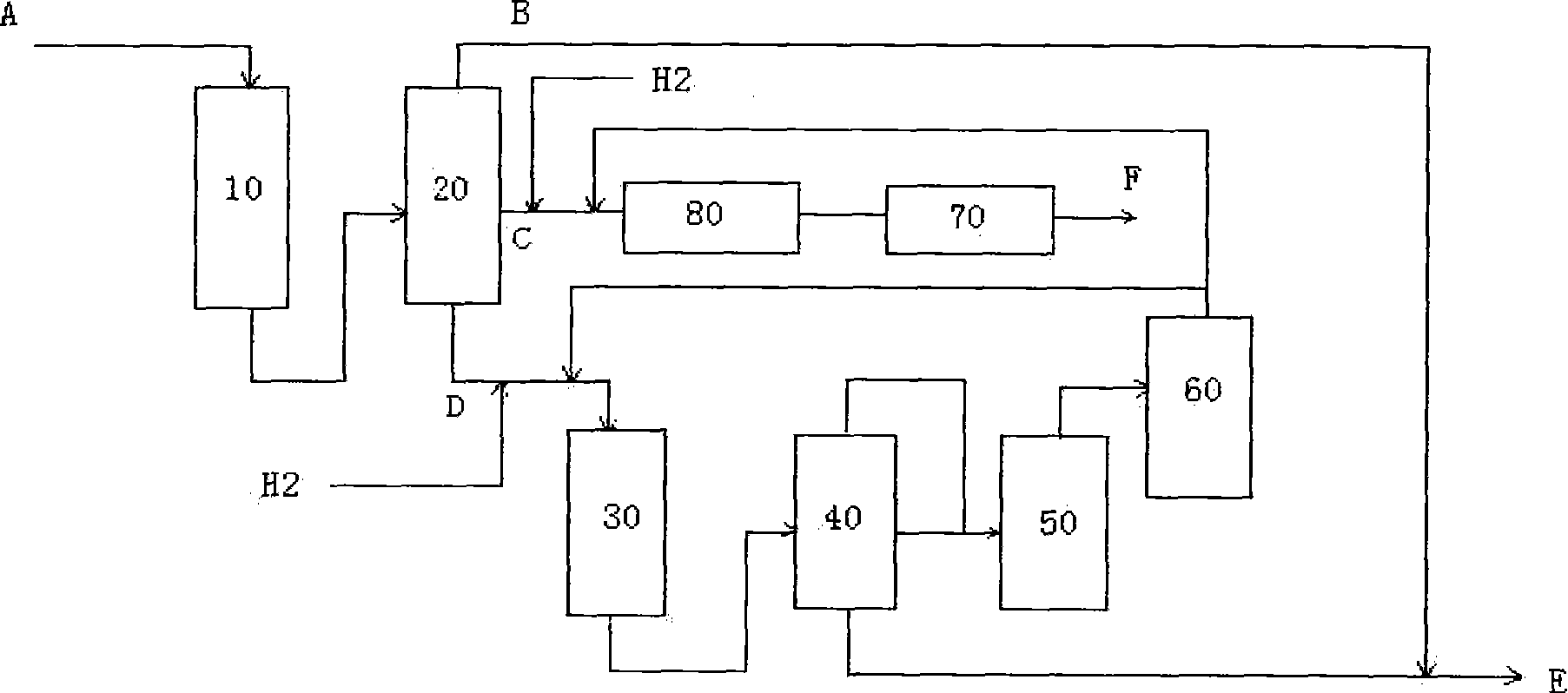

Method used

Image

Examples

Embodiment

[0041] This example gives a catalytic cracking gasoline desulfurization effect. Those skilled in the art can determine specific operating conditions according to the properties of raw materials and product quality requirements.

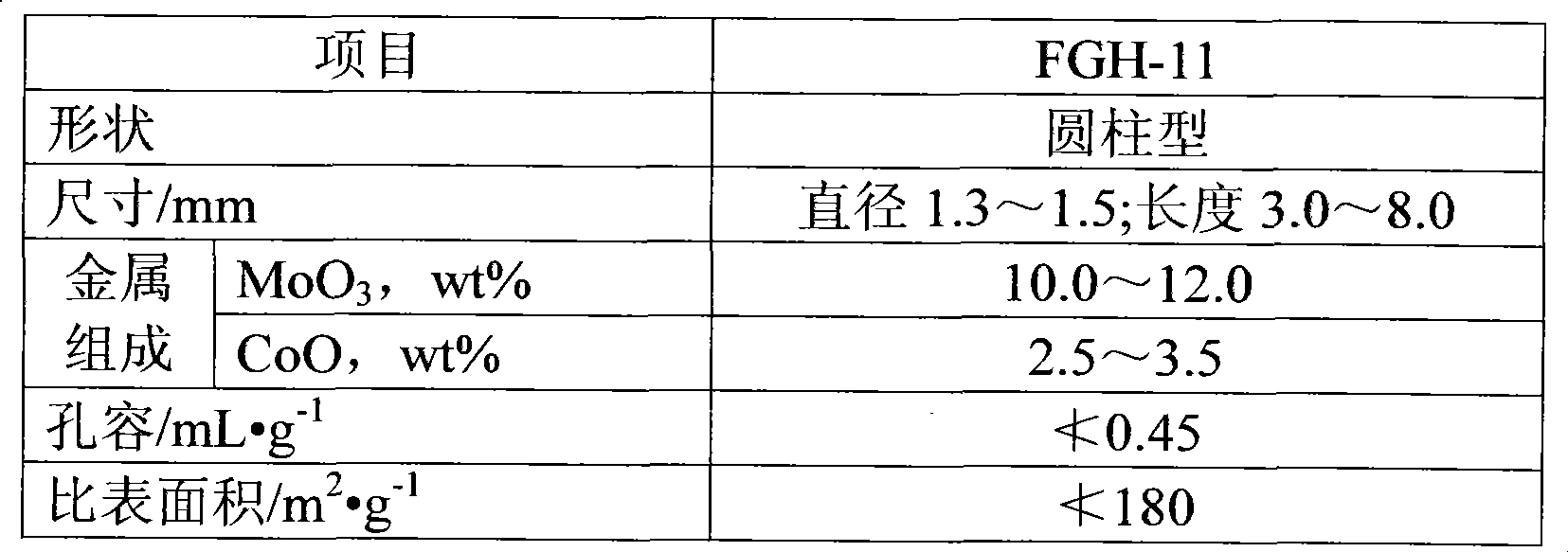

[0042] The catalyst is an industrial catalyst produced by Wenzhou Huahua Group Company.

[0043] Table 1 Catalyst physical and chemical properties

[0044]

[0045] 1), crude oil sweetening

[0046] The raw oil sweetening oxidant adopts commercial AFS-12 catalyst (produced by Petroleum University), at a pressure of 0.5MPa, a temperature of 35°C-45°C, and a volume space velocity of 2.0h -1 , Gas-oil volume ratio (air / gasoline) 4:1 for deodorization.

[0047] 2) Raw oil cutting data

[0048] The deodorized gasoline fraction is cut into light boiling range naphtha, medium boiling range naphtha and heavy boiling range naphtha, and the fractions are 6 、C 6 ~145°C, >145°C.

[0049] Table 2 Properties of each component of FCC gasoline after cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com