Single-hook screw thread and end plane metal self-sealing expansion sleeve pipe

An expansion sleeve and metal sealing technology, which is applied in the threaded structure of expansion sleeve joint connection and the field of expansion sleeve, can solve the problem that the thread cannot be processed directly, achieve low processing cost, simple and feasible processability, and eliminate stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Taking a single-hook threaded and end metal self-sealing expansion sleeve with a nominal diameter of 139.7mm as an example, the invention is further described in detail.

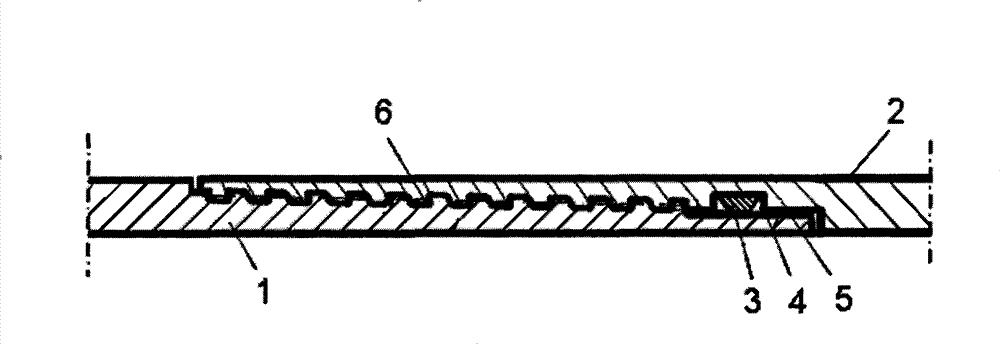

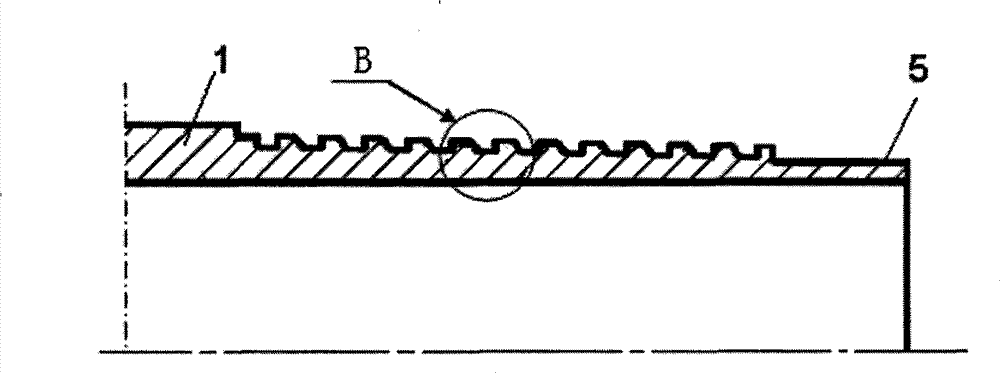

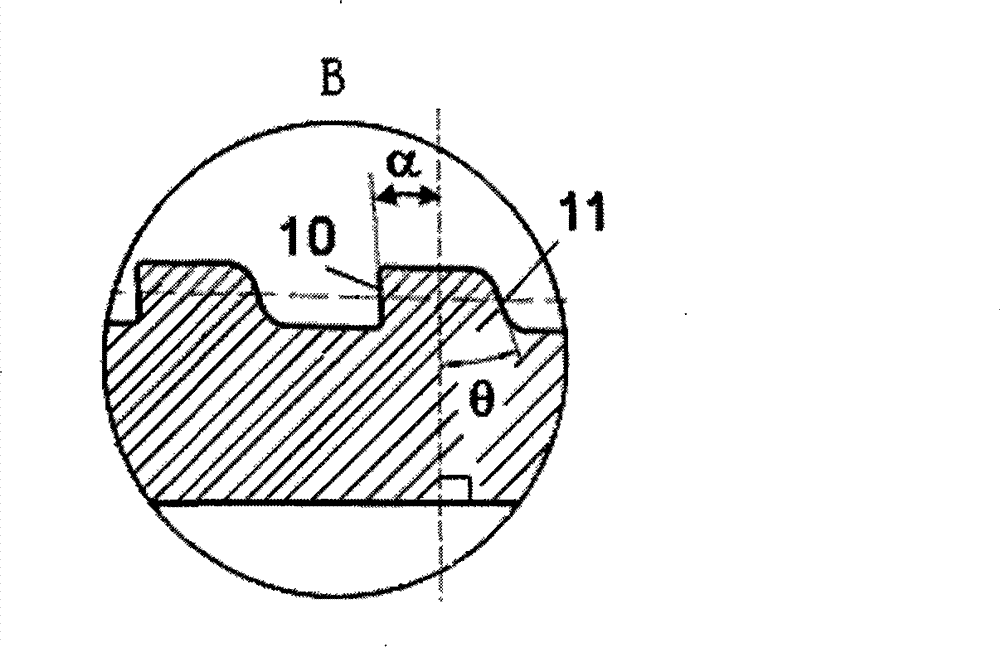

[0018] Single hook thread and end metal self-sealing expansion sleeve, the nominal diameter is 139.7mm, the thickness of the pipe body is 9.17mm, and the length of the pipe body is 9m. There are externally threaded ends 1 and internally threaded ends 2 at both ends of the pipe body. The externally threaded end 1 and the internally threaded end 2 have a single hook thread 6 . refer to figure 1 . After the two expansion sleeves are connected, the single hook thread 6 of the external thread end 1 cooperates with the single hook thread 6 of the external thread end 1 to form a metal seal on the thread hook surface. refer to figure 2 . The thread taper of the single hook thread 6 at the external thread end 1 is 1:24, and the pitch of the thread is 6.35 mm. refer to image 3 . The heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com