Ultrasonic cavitation pressure measuring device and measurement method thereof

A measuring device, ultrasonic technology, applied in the direction of fluid pressure measurement using acoustic methods, etc., to achieve the effect of ensuring accuracy, small size, and high natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

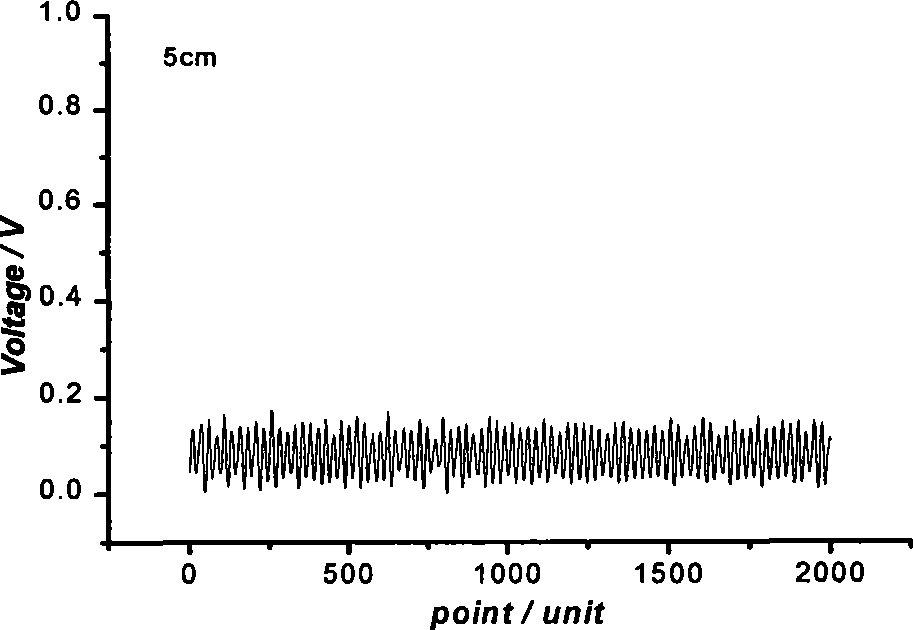

Examples

Embodiment 1

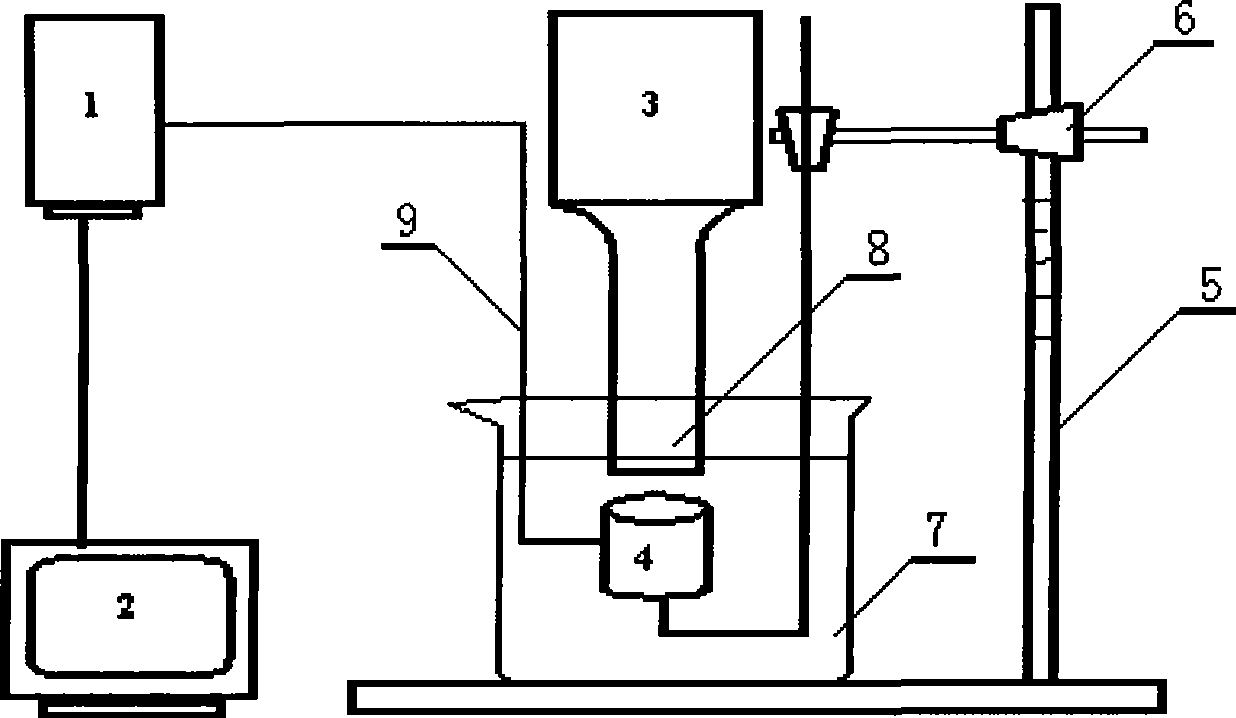

[0023] The invention relates to a measuring device for ultrasonic cavitation pressure, which includes an ultrasonic generator, a piezoelectric quartz force sensor, a charge amplifier, a computer data acquisition device, and a support that can adjust the precise height. The device is to set the piezoelectric quartz force sensor on the support so that the measuring surface is facing the probe of the ultrasonic generator, and then the signal line of the sensor is connected to the input end of the amplifier, and the output end of the amplifier is connected to the computer data acquisition device.

[0024] The main principle of the present invention is to measure the pressure of ultrasonic wave in water with piezoelectric quartz force sensor. Piezoelectric sensor is a kind of electromechanical transducer, which is characterized by simple structure, firmness, convenient installation, small size, light weight and long life; wide frequency response range and good stability. Using the ...

Embodiment 2

[0026] The present invention is used for the measuring method of measuring device, and concrete steps are as follows:

[0027] (1) Measurement steps

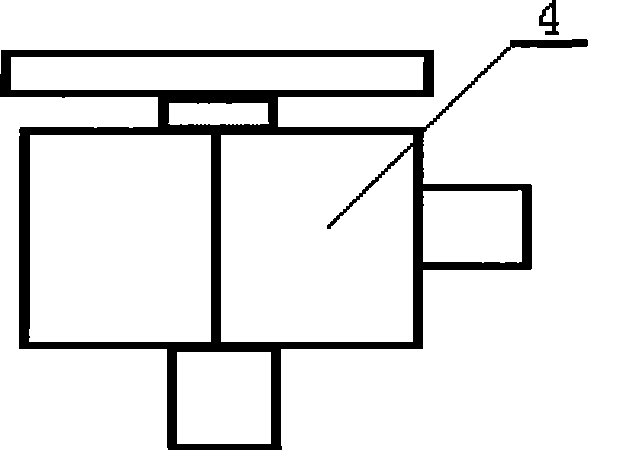

[0028] 1. The structure of the sensor see figure 2 , Before measuring, the signal socket of the sensor should be connected with the signal line, and the signal line connection should be sealed with epoxy resin to achieve absolute waterproof effect, and it should be used after 24 hours of drying.

[0029] 2. Fix the sensor on a metal bracket that can move up and down. The moving distance can be measured by the scale on the bracket, such as figure 1 shown.

[0030] 3. Put the sensor into the water, the measuring surface of the sensor is facing the lower part of the ultrasonic probe, and adjust the distance between the measuring surface and the probe.

[0031] 4. Immerse the ultrasonic probe 5mm below the horizontal surface, connect the signal line of the sensor to the input terminal of the charge amplifier, and connect the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com