Nimesulide sustained-release tablet and preparation method thereof

A sustained-release tablet and compressibility technology, applied in the field of nimesulide sustained-release tablets, to achieve the effects of reducing surface tension, good process reproducibility, and reducing the number of times of taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

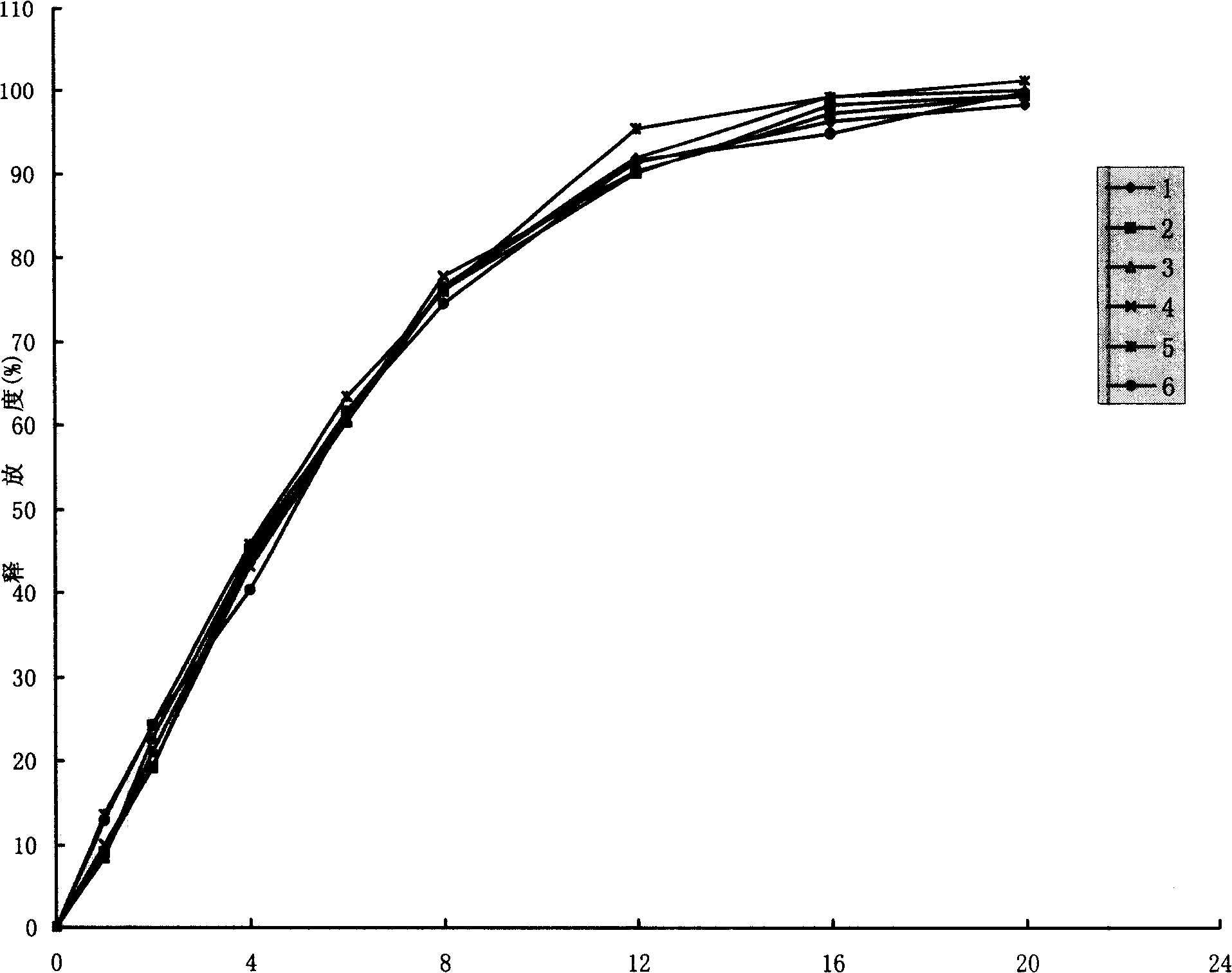

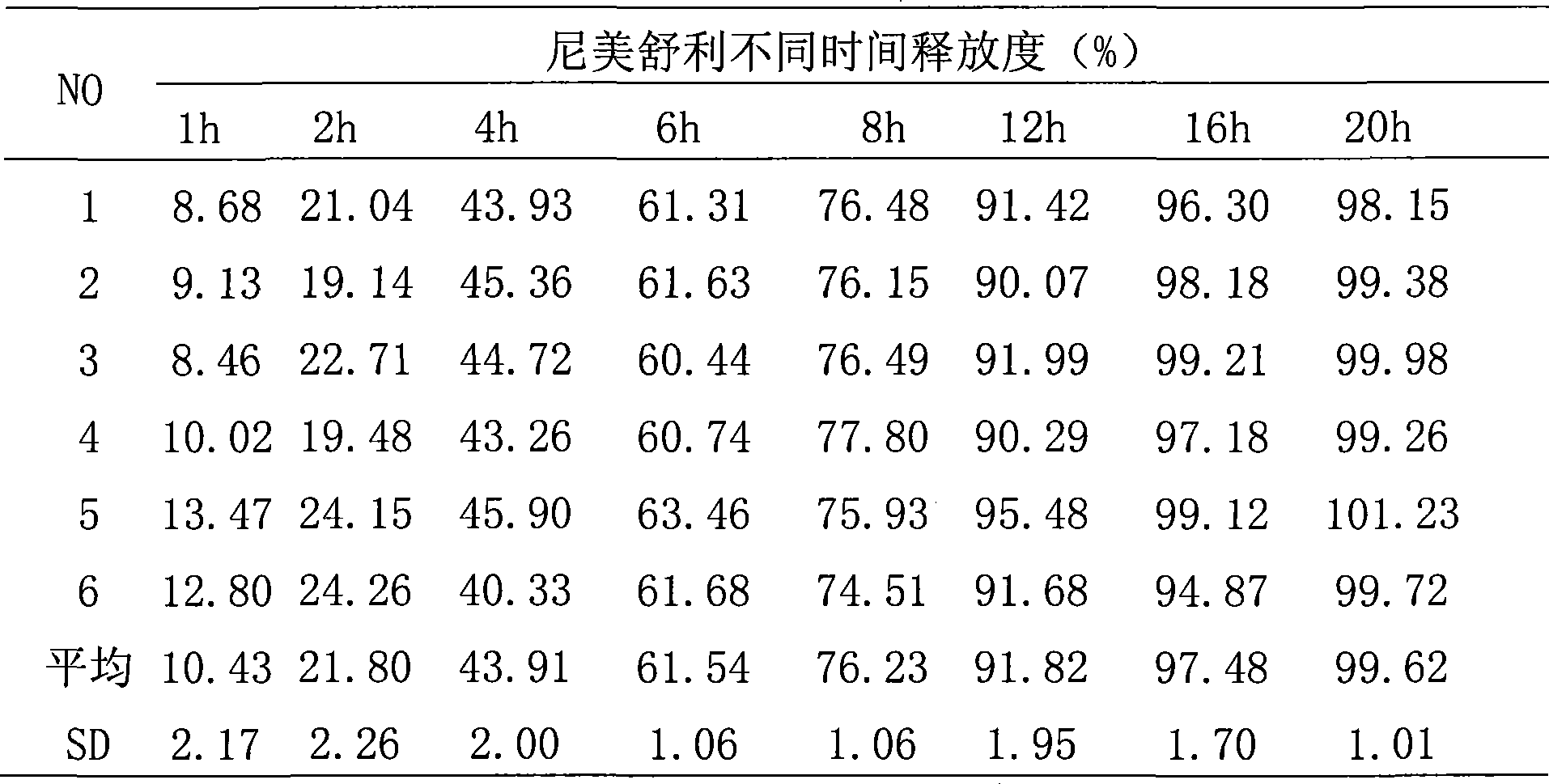

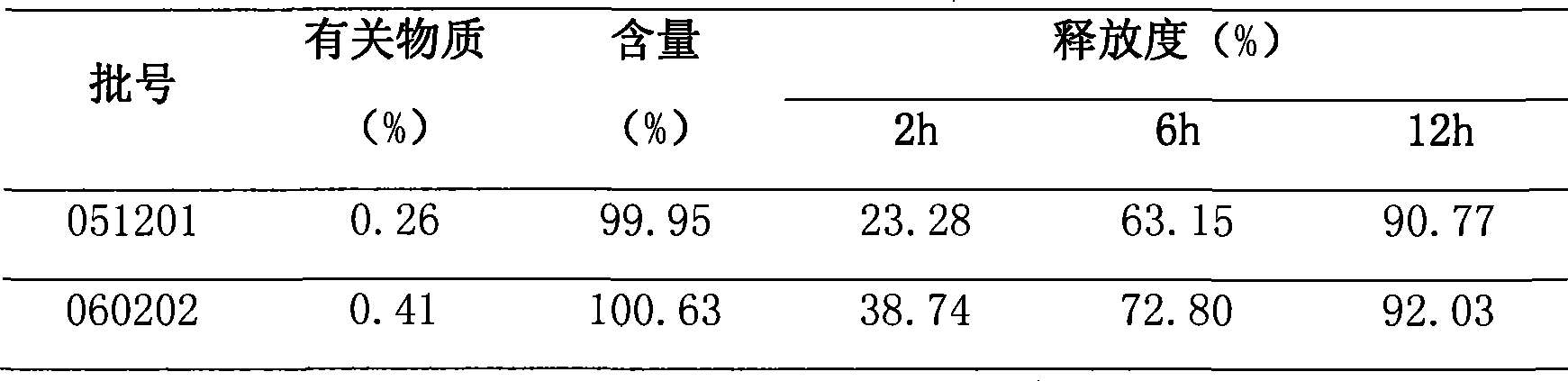

Image

Examples

Embodiment 1

[0021] 1000 Nimesulide Sustained Release Tablets, each containing Nimesulide 200mg.

[0022] Nimesulide 200g,

[0023] Hypromellose 60RT50 100g,

[0024] Compressible starch 100g,

[0025] Magnesium Stearate 5g,

[0026] 2.5% ethyl cellulose 95% ethanol solution 140ml.

[0027] Preparation method: mix nimesulide, hypromellose, compressible starch, etc. uniformly according to the method of equal amount addition, and use 140ml of 2.5% ethylcellulose and 95% ethanol solution to make the powder after mixing uniformly Material, pass through 16 mesh sieve to granulate, ventilate and dry at 55~60℃, control water content <3%, after granulation with 14 mesh sieve, add magnesium stearate in prescribed amount, mix well, compress into tablets, control tablet The hardness is between 6.5 and 7.5kg.

Embodiment 2

[0029] 1000 Nimesulide Sustained Release Tablets, each containing Nimesulide 200mg.

[0030] Nimesulide 200g,

[0031] High viscosity hypromellose 90g,

[0032] Low viscosity hypromellose 10g,

[0033] Compressible starch 100g,

[0034] Magnesium Stearate 5g,

[0035] 2.5% ethyl cellulose 95% ethanol solution 140ml.

[0036] Preparation method: mix high-viscosity hypromellose and low-viscosity hypromellose to form hypromellose with a viscosity of 4000 milliPascal seconds, and add nimesulide and hypromellose to , compressible starch, etc., mix well, use 140ml of 2.5% ethyl cellulose and 95% ethanol solution to make the above mixed powder into a soft material, pass through a 16-mesh sieve to granulate, and ventilate and dry at 55-60°C to control the content of The amount of water is less than 3%. After the granules are sized with a 14-mesh sieve, the prescribed amount of magnesium stearate is added, mixed evenly, and compressed into tablets. The hardness of the tablets is c...

Embodiment 3

[0038] 1000 Nimesulide Sustained Release Tablets, each containing Nimesulide 200mg.

[0039] Nimesulide 200g,

[0040] High viscosity hypromellose 65g,

[0041] Low viscosity hypromellose 35g,

[0042] Compressible starch 100g,

[0043] Magnesium Stearate 5g,

[0044] 4.5% polyvinylpyrrolidone 95% ethanol solution 120ml.

[0045] The preparation method is the same as in Example 2, wherein the high viscosity hypromellose and the low viscosity hypromellose are mixed to form the hypromellose with a viscosity range of 2000 milliPascals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com