Microwave heating and sterilizing method and device of liquid material

A technology of microwave heating and microwave heating chamber, which is applied in the fields of chemical engineering, bioengineering, food and environmental engineering, can solve the problems of not being able to withstand hydraulic pressure, etc., and achieve the effect of consistent performance, sufficient accessories, and easy purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

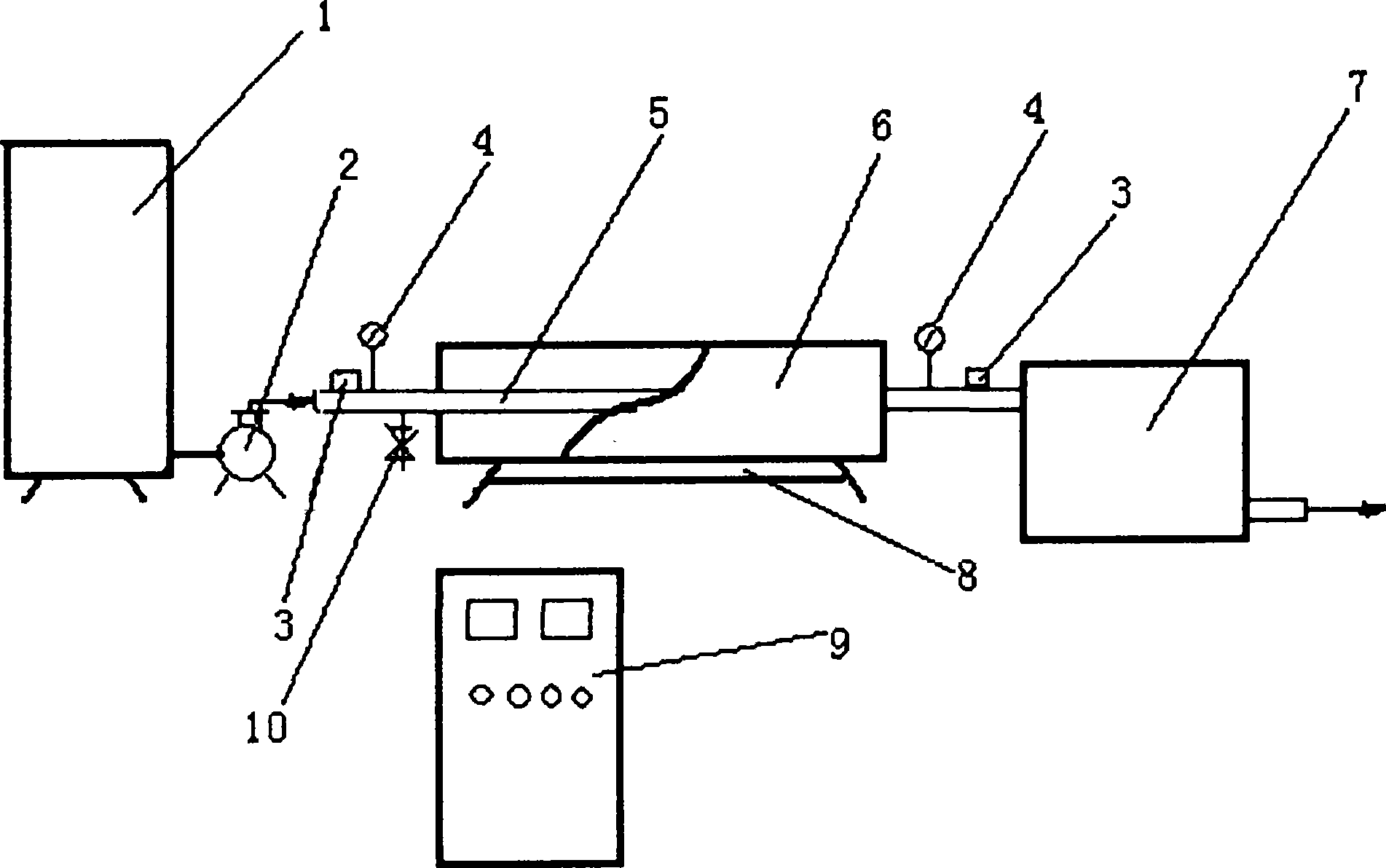

Embodiment Construction

[0024] 1. In the production process of soy sauce and vinegar, bottled and bagged soy sauce and vinegar need to be sterilized before packaging. The soy sauce or vinegar that needs to be sterilized in the storage tank (1) is pressed into the heating tube (5) by the hydraulic pump (2), and is heated and sterilized by the microwave heating chamber (6). The sterilization temperature and sterilization time are determined by Microwave heating power, temperature measuring and controlling instrument and hydraulic pressure and liquid material flow speed adjustment control, the sterilized material is cooled rapidly by the cooler (7), the whole cooling process can be carried out in stages, and part of the cooling medium can be liquid material that needs to be heated and sterilized , so that the liquid material to be sterilized can be preheated during the cooling process, and the sterilized material can be cooled to reduce energy loss. Sterilized liquid materials are packaged aseptically. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com