Twin driving chain hoister

A hoist and double-drive technology, applied in the field of high-efficiency self-locking hoist, can solve the problems of low energy utilization rate, poor controllability and reliability of the hoisting machine, and achieve the effect of compact structure, high reliability and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

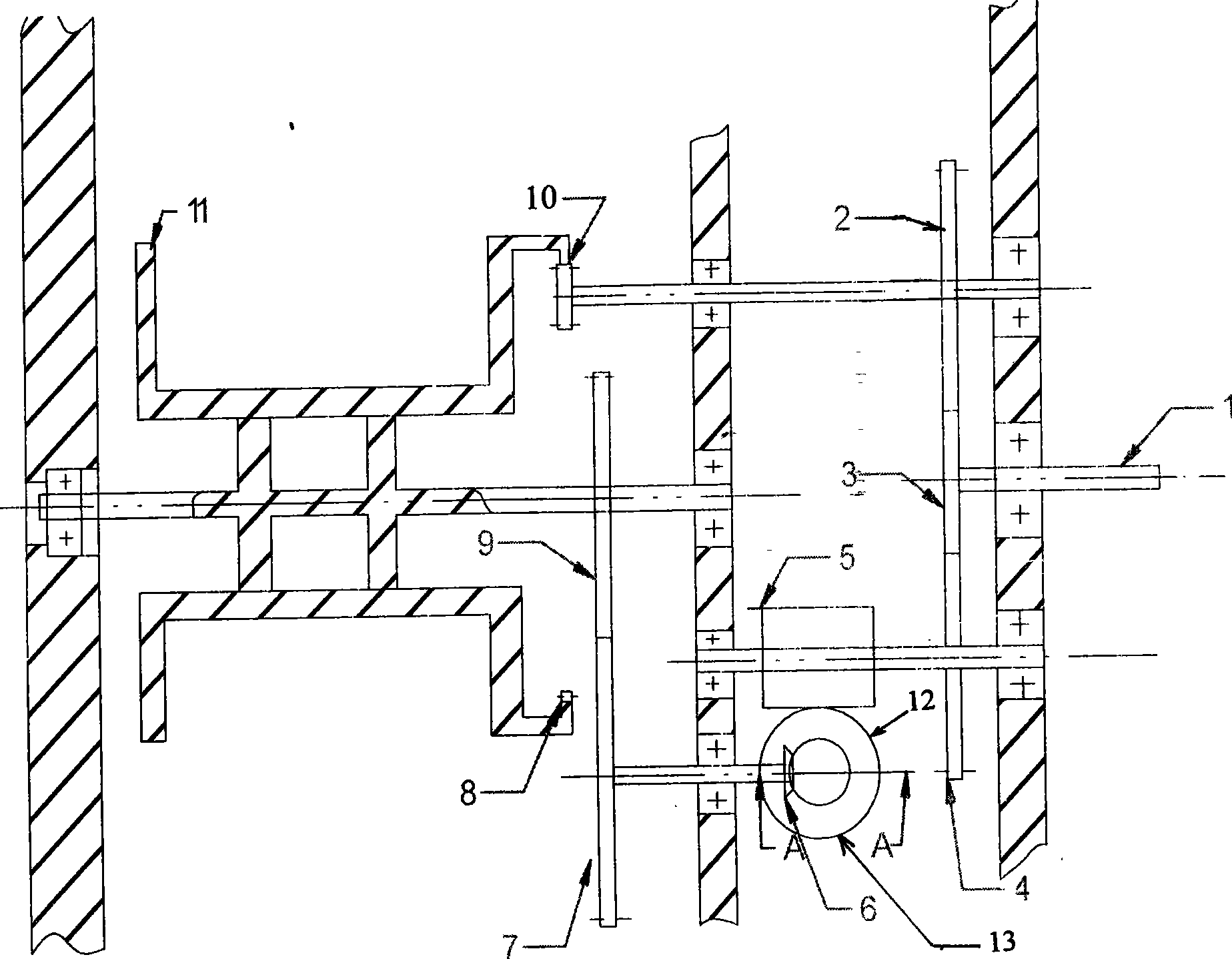

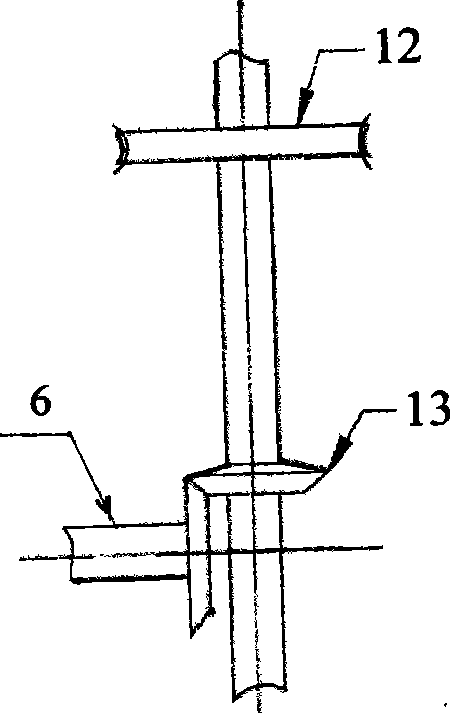

[0018] see figure 1 , figure 2 This double transmission chain hoist has a driver, a transmission mechanism and a reel that are linked in sequence. The transmission mechanism is two sets, one of which is a lifting transmission mechanism, and the other is a lowering transmission mechanism.

[0019] The output shaft 1 of the driver is equipped with a spur gear 3, and an internal ring gear 8 is provided on the edge of the reel 11, and a spur gear 9 is arranged on the reel shaft.

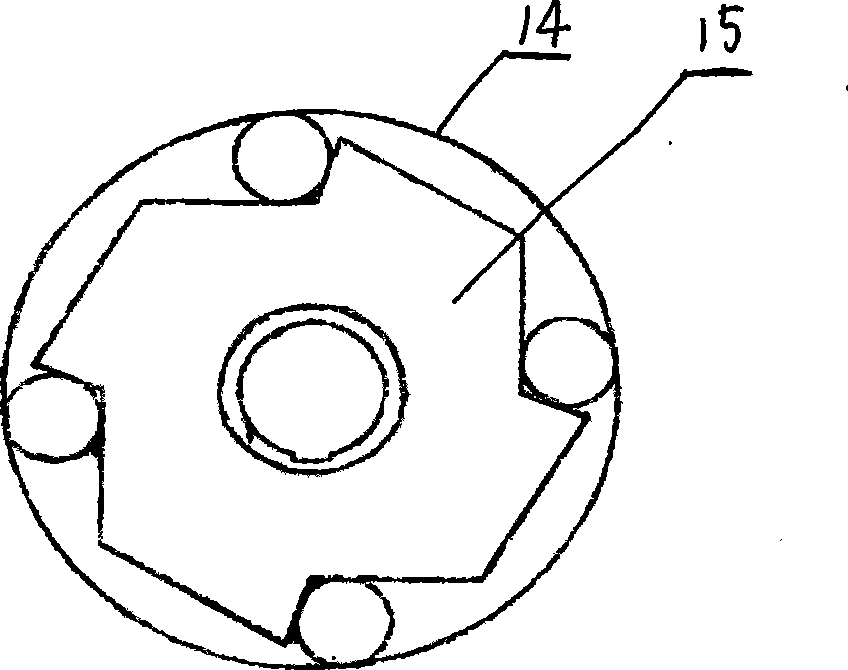

[0020] The lifting transmission mechanism adopts a spur gear transmission pair. The spur gear transmission pair has a coaxial input spur gear 2 and an output spur gear 10. The input spur gear 2 meshes with the drive output shaft spur gear 3, and the output spur gear 10 meshes with the internal teeth of the reel. The ring 8 meshes, and the output spur gear 10 contains an overrunning clutch. Also can contain overrunning clutch in input spur gear 2, input spur gear 2, output spur gear 10, arbitrary one c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com