Station boiler and water and oxygen supply apparatus and method thereof

A power plant boiler and oxygen replenishment technology, which is applied in the direction of adding substances to water/sewage treatment, etc., can solve the problems of high pressure at the oxygen addition point, unfavorable adjustment, and increased requirements for system design and installation, and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are illustrated. In the drawings, the same reference numerals designate the same or similar elements or components.

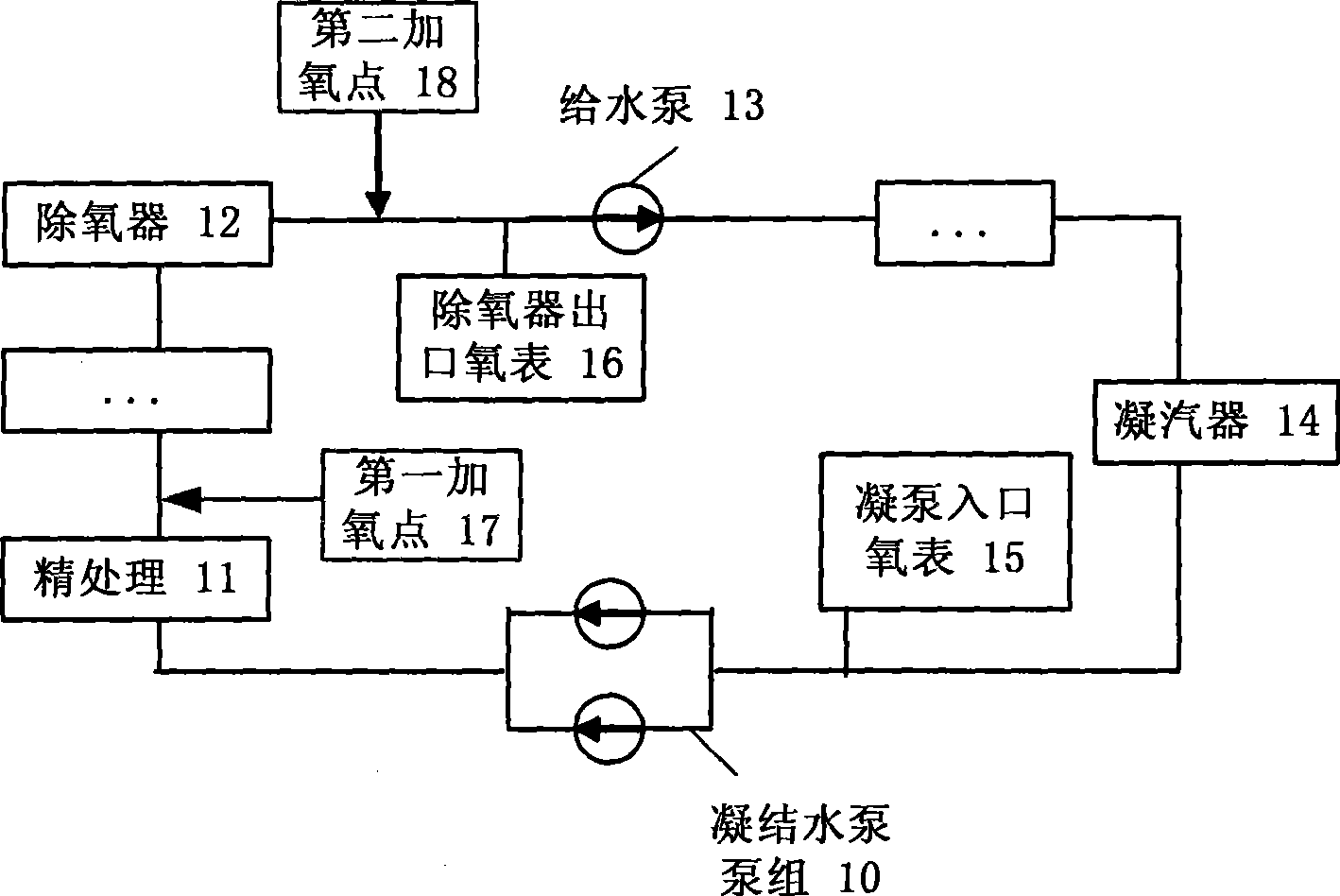

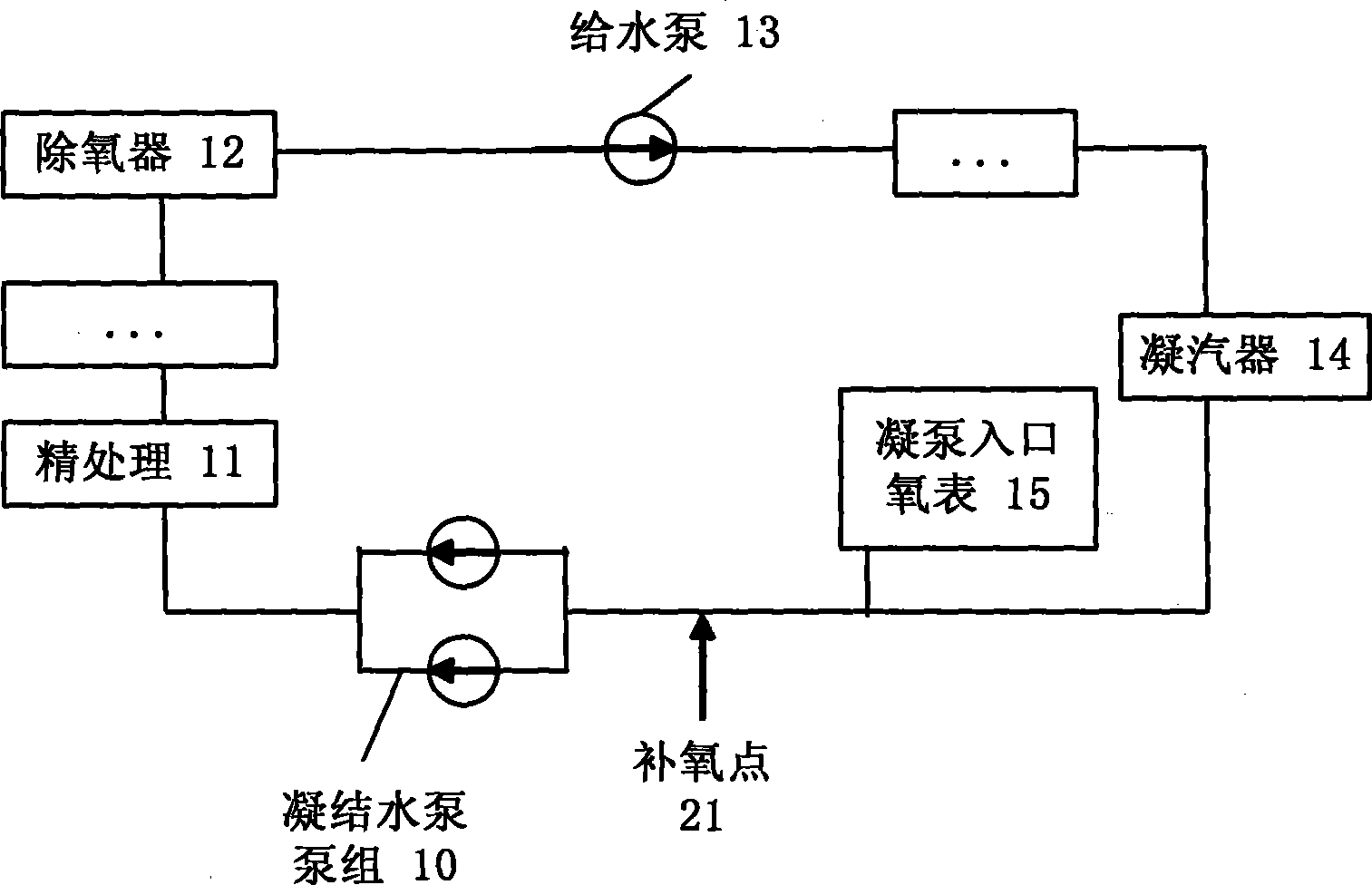

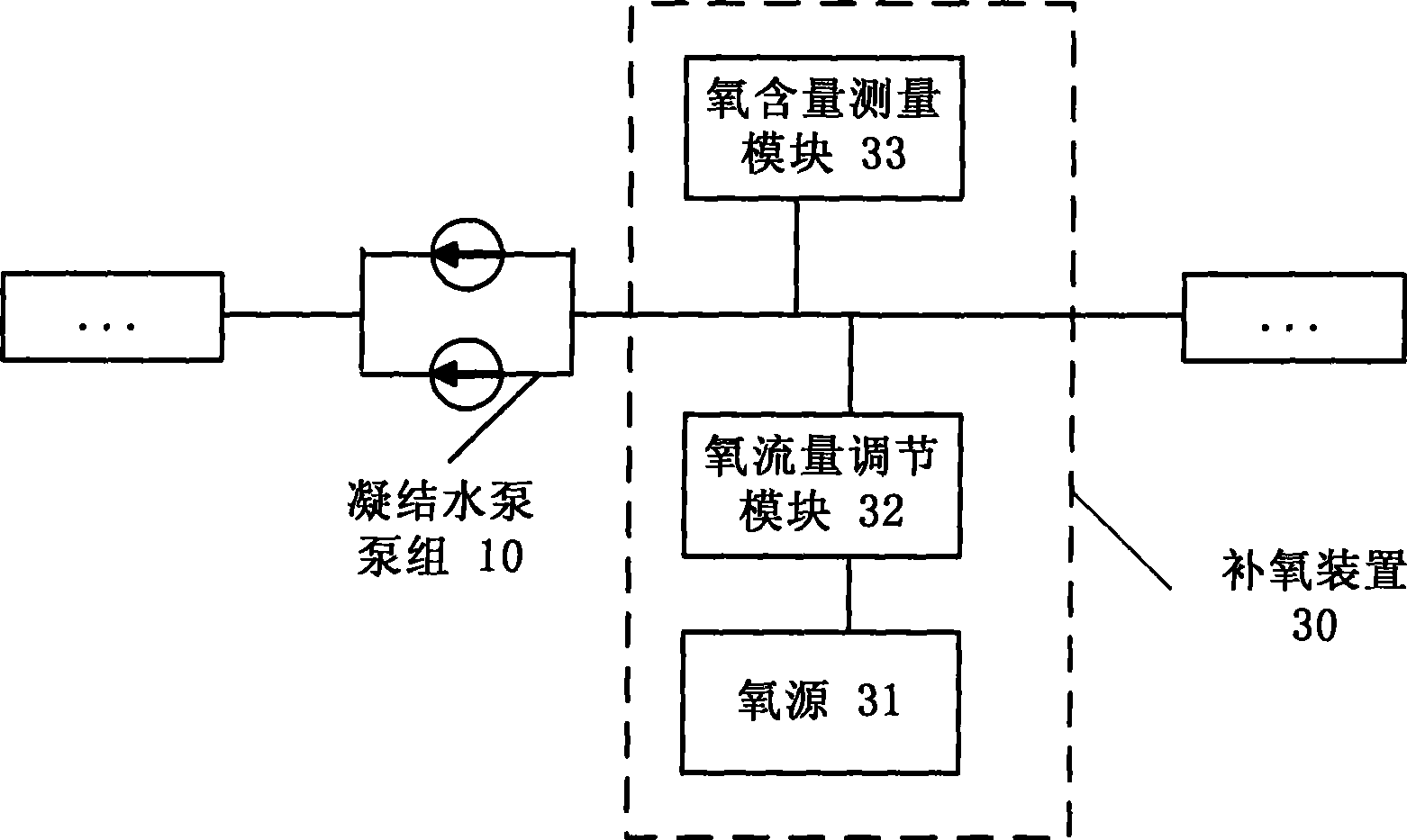

[0025] The present invention proposes a new weak oxidative treatment (WOT) oxygen supply method. The control of dissolved oxygen by WOT supplementary oxygen method follows the two target upper limits of AVT (O) method: condensed water dissolved oxygen ≤ 30ug / L, and deaerator outlet (or economizer inlet) ≤ 10ug / L. Due to the risk of corrosion in the above two places where the dissolved oxygen is too high, the following requirements are formed for oxygen supplementation: 1) First, control the dissolved oxygen in condensed water to ≤30ug / L to prevent corrosion risks; 2) The outlet of the deaerator (or economizer Inlet) dissolved oxygen should be controlled near the upper limit of 10ug / L to ensure the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com