High conductivity, high intensity and heat resisting aluminum alloy conducting wire and method for producing the same and conducting wire

An aluminum alloy wire, high conductivity technology, applied in heat-resistant aluminum alloy wire and its manufacture, heat-resistant aluminum alloy wire wire, high conductivity, high strength field, can solve the problem of low strength of heat-resistant wire and temperature rise of wire High, sag increase and other problems, to achieve the effect of reducing investment cost, increasing power transmission capacity, and increasing laying span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

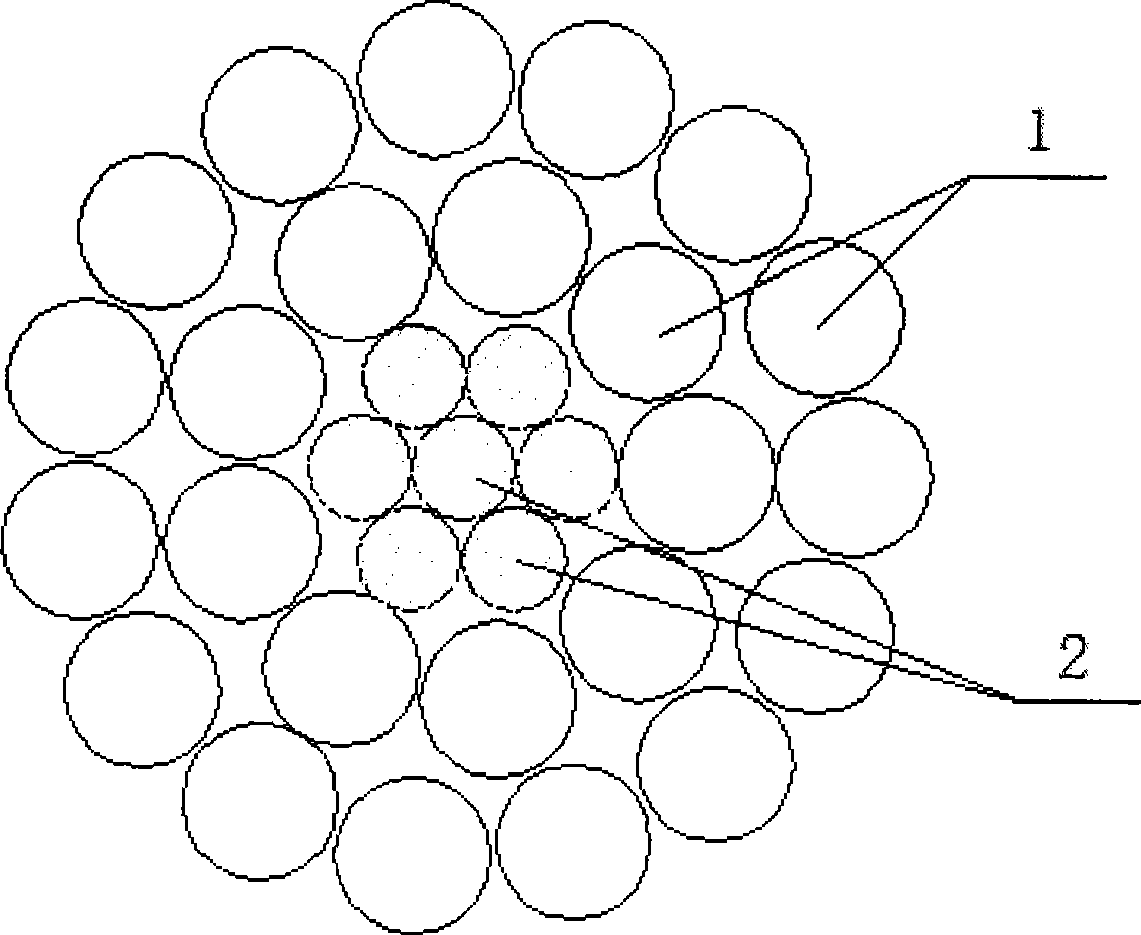

[0027] Example 1, select the aluminum ingot with the brand name AI99.85 for remelting, add metal elements zirconium, iron, silicon, magnesium, and rare earth, and raise the temperature to 743°C in 3.5 hours, within the speed range of not more than 10 cycles per minute, Stir for 10 minutes, after conventional procedures such as scouring, degassing, slag removal, feeding, etc., put it aside for 45 minutes before furnace analysis, the content is: zirconium Zr 0.28%, iron Fe 0.49%, silicon Si 0.22%, magnesium Mg0.62 %, rare earth RE 0.18%, control the sum of copper Cufigure 1 As shown, the G2A type high-strength steel strands are 7 pieces of Φ2.40mm, and the aluminum alloy single wires are 24 pieces of Φ3.60mm, which are formed by concentric stranding to form 240 / 30mm 2 High conductivity, high strength, heat-resistant aluminum alloy wire. After testing, the conductivity is not less than 58.0% IACS, the tensile strength is 272MPa, the residual strength rate is not less than 90% whe...

Embodiment 2

[0028]Example 2, select an aluminum ingot with the brand name AI99.85 for remelting, add metal elements zirconium, iron, silicon, magnesium, and rare earth, and heat up to 735°C in 2.5 hours, within the speed range of not more than 10 cycles per minute, Stir for 12 minutes, after conventional procedures such as scouring, degassing, slag removal, feeding, etc., put it aside for 45 minutes before furnace analysis. The content is: zirconium Zr 0.20%, iron Fe 0.39%, silicon Si 0.14%, magnesium Mg0.54 %, rare earth RE 0.16%, control copper Cu2 High conductivity, high strength, heat-resistant aluminum alloy wire. After testing, the electrical conductivity is 58.0% IACS, the tensile strength is 265MPa, the strength residual rate is 90% when the long-term heat resistance is 150°C, and the elongation rate is 2.5%.

Embodiment 3

[0029] Example 3, select an aluminum ingot with the brand name AI99.85 for remelting, add metal elements zirconium, iron, silicon, magnesium, and rare earth, and raise the temperature to 735°C in 2.5 hours, within the speed range of not more than 10 cycles per minute, Stir for 15 minutes, after scouring, degassing, slag removal, feeding and other conventional procedures, after standing still for 45 minutes before the furnace analysis, the content is: zirconium Zr 0.34%, iron Fe 0.62%, silicon Si 0.26%, magnesium Mg0.68 %, rare earth RE 0.21%, control the sum of copper Cu2 High conductivity, high strength, heat-resistant aluminum alloy wire. After testing, the conductivity is not less than 58.0% IACS, the tensile strength is 278MPa, the residual strength rate is not less than 90% when the long-term heat resistance is 150°C, and the elongation rate is 2.1%.

[0030] The wire of the invention has high conductivity, high strength and good heat resistance, can not only increase the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com