Reinforcement steel bar for medium-high strength hoop for rods for reinforcing concrete and method for producing the same

A technology of reinforced concrete and a manufacturing method, which is applied in the field of steel bar products and its manufacturing, can solve the problems of no stirrup products and no intermediate strength stirrup manufacturing methods, etc., and achieves convenient construction, enhanced strength, and saving steel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

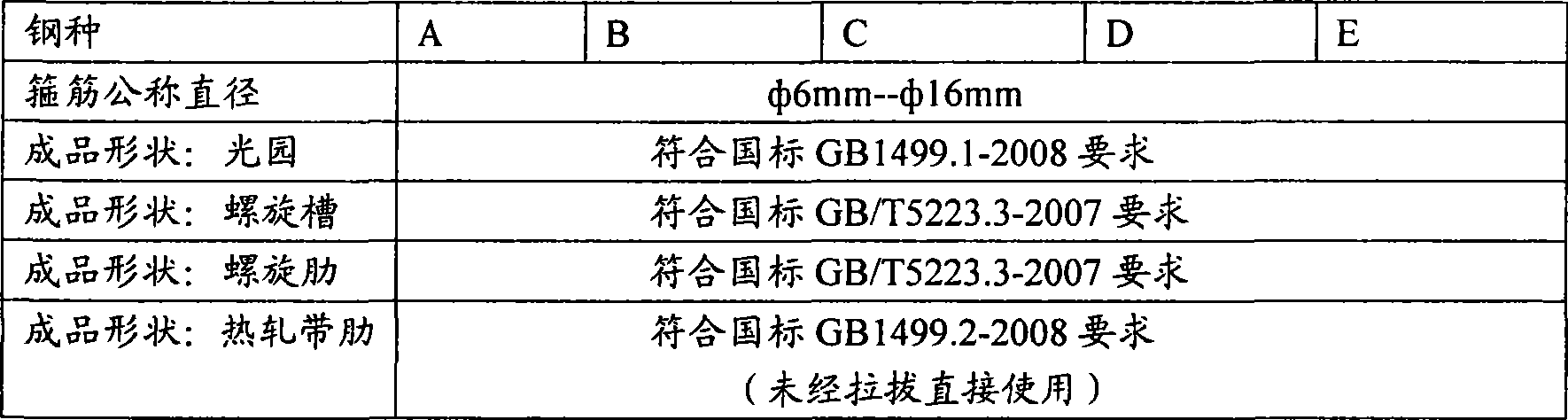

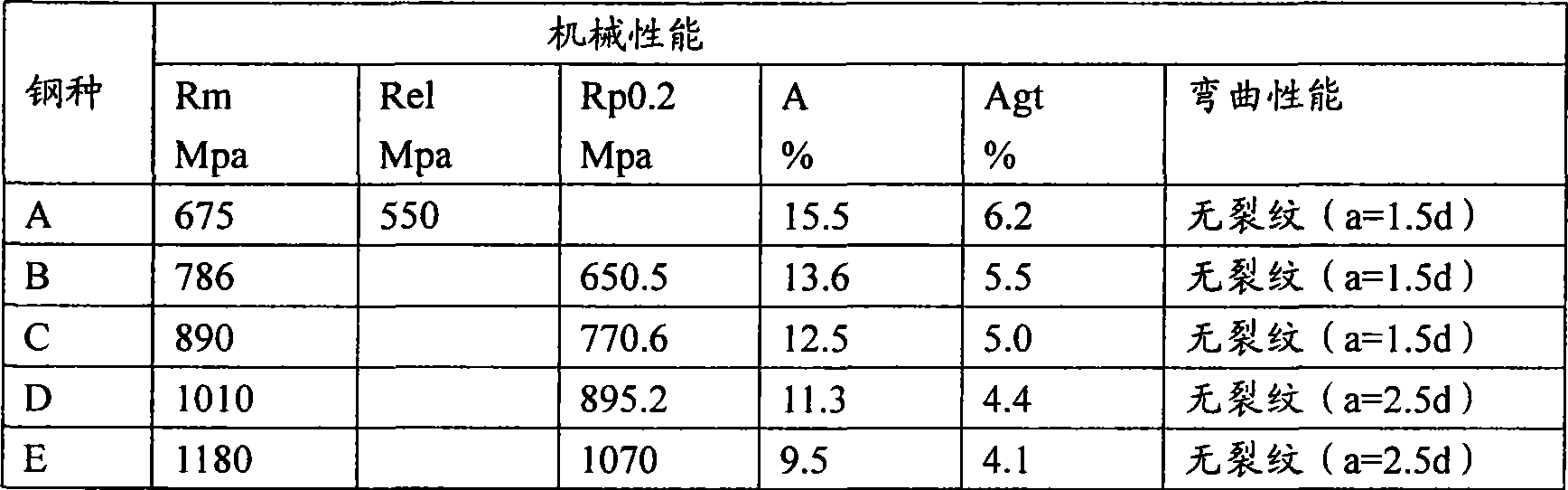

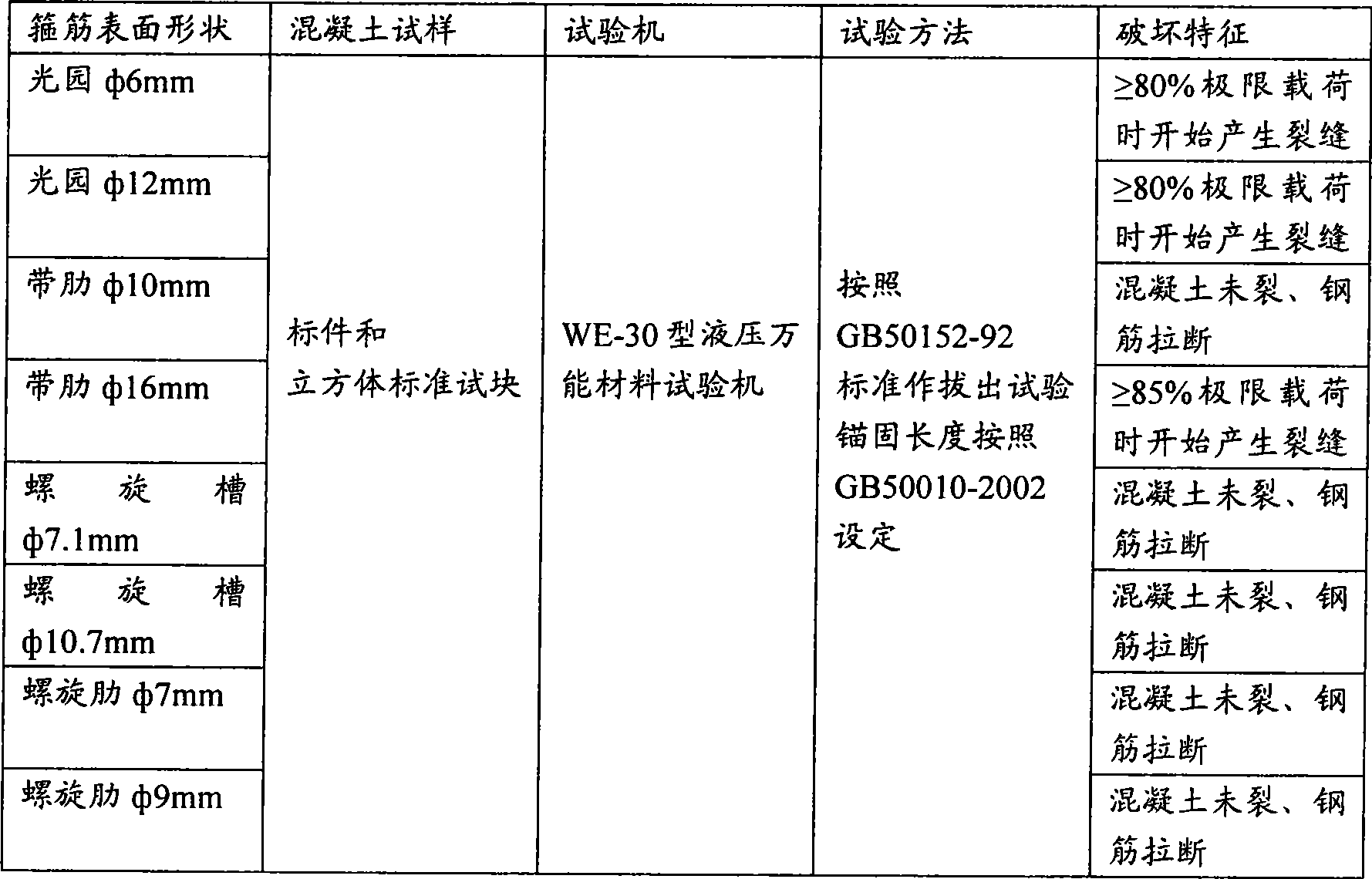

[0068] Example 1 , in weight %, containing 0.15-0.30% C, 0.5-1.5% Mn, ≤2.0% Si, the rest is Fe and unavoidable impurities of hot-rolled wire rod, after mechanical descaling, rotary die continuous drawing into a smooth Round, spiral groove or spiral rib shape stirrups are used.

Embodiment 2

[0069] Example 2 , using low-carbon steel hot-rolled wire rods with a composition of more than 0.15% C, more than 0.25% Si, and more than 0.65% Mn as raw materials, which are mechanically derusted and continuously drawn by a rotary die into a light garden, spiral groove or spiral rib shape, or Direct heat treatment without drawing. The heat treatment temperature is: quenching temperature 950-1050°C, tempering temperature 400-550°C. Can produce ф6-ф16mm, 600N / mm 2 A steel bar for stirrups with the above yield strength, 12-15% elongation, and no cracks after bending for 1.5 days.

Embodiment 3

[0070] Example 3 , using low-carbon steel hot-rolled wire rods with a composition of more than 0.18% C, more than 0.55% Si, and more than 0.85% Mn as raw materials, which are mechanically derusted and continuously drawn by a rotary die into a light garden, spiral groove or spiral rib shape, or Direct heat treatment without drawing. The heat treatment temperature is: quenching temperature 900-1000°C, tempering temperature 400-500°C. Can produce ф6-ф16mm, 750N / mm 2 Stirrup bars with above yield strength, 10-15% elongation, and no cracks after bending for 1.5 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com