Down-in type marginal oil field underwater drilling basal disc for drilling ship and manufacture and installation method

A technology for drilling templates and drilling ships, which is applied in the direction of manufacturing tools, boreholes/well components, and other manufacturing equipment/tools. Effects of base plate weight, reduction of section size, and reduction of base plate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

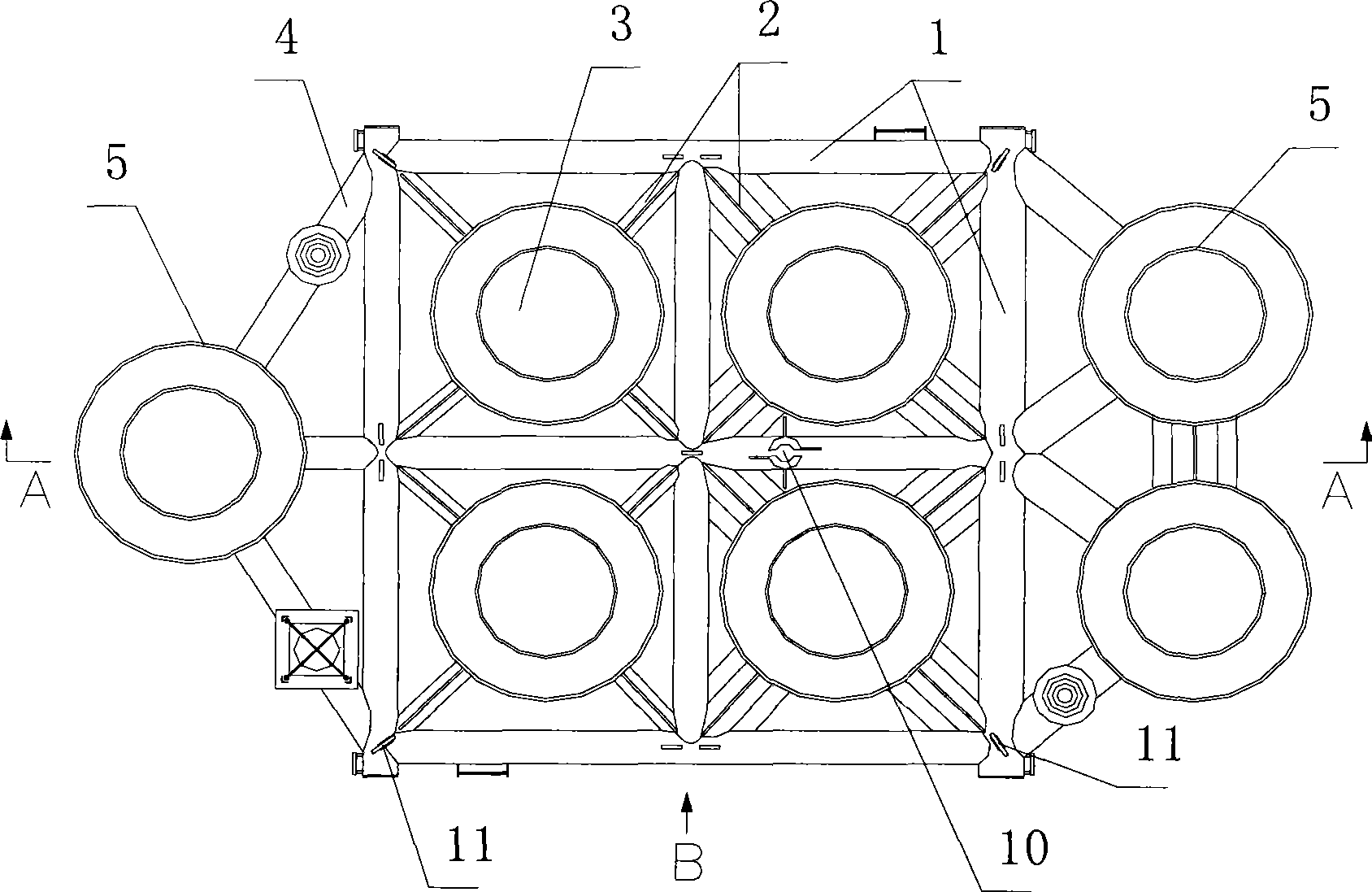

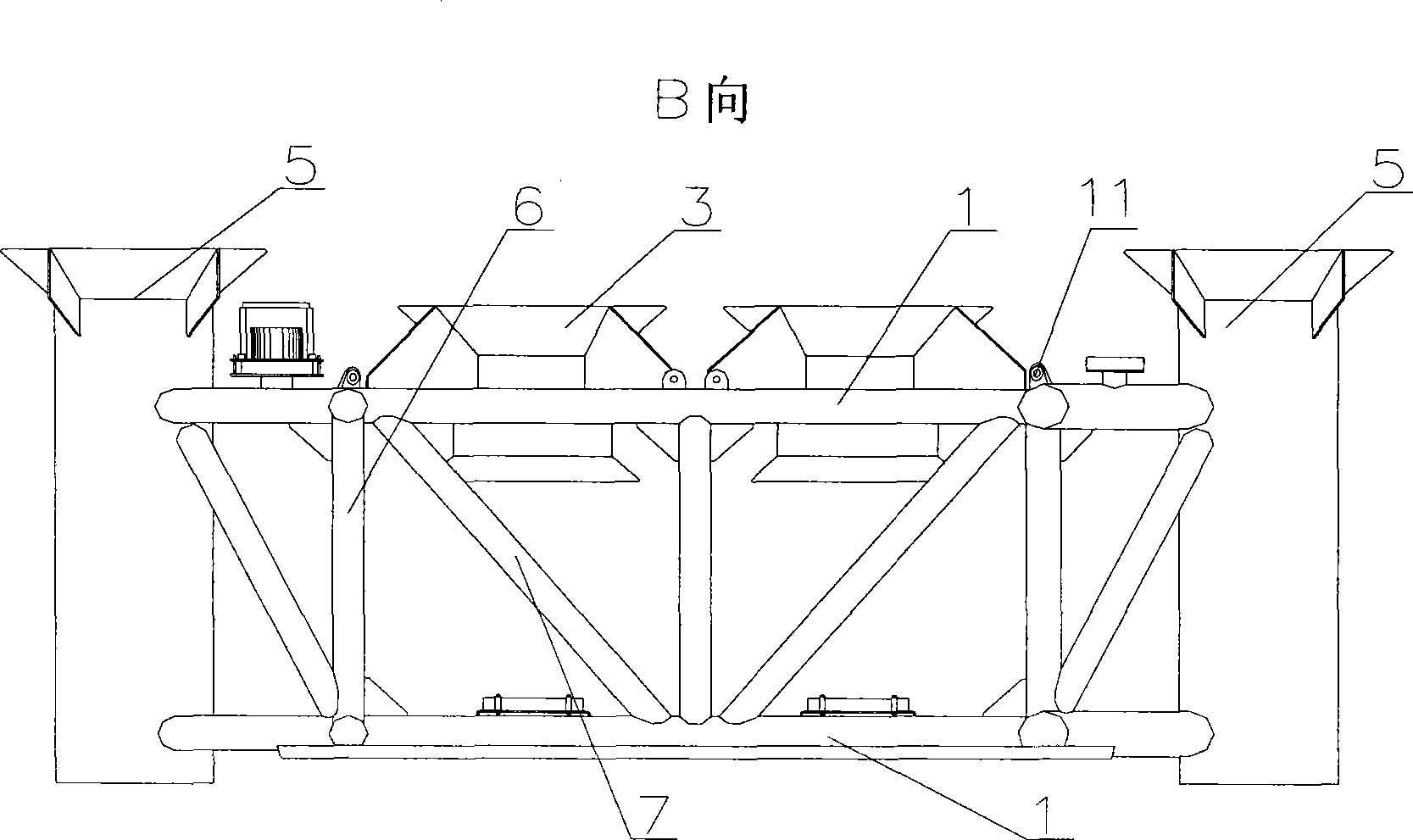

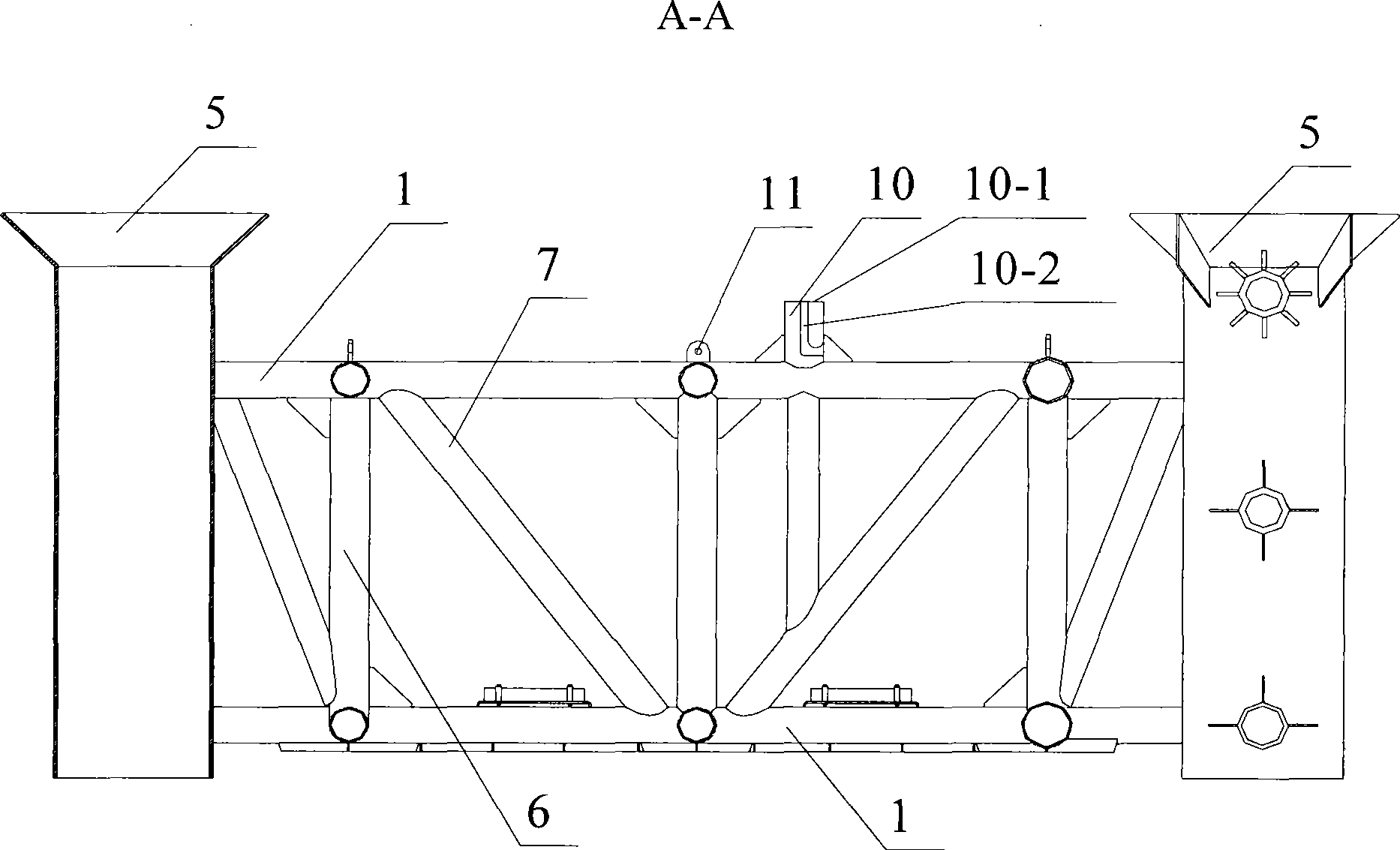

[0030] like figure 1 , 2 As shown in , 3, a drill ship's entry-in type marginal oil and gas field underwater drilling template has 4 wellheads in total, including the main frame of the template and accessories, wherein the main frame of the template is composed of horizontal rods 1 and vertical rods 6 fixed rectangular parallelepiped frame body, the main frame of the base plate is provided with a vertical well hole sleeve 3, and pile pipe sleeves 5 are fixed on both sides through the support rod 4, between the horizontal rods 1, the horizontal rods 1 and the horizontal rods 1 An oblique support rod is arranged in the rectangular frame formed between the vertical rods 6, and the vertical well hole sleeve 3 is arranged at the center of the rectangle surrounded by the horizontal rods 1, and one end of the oblique support rod 2 between the horizontal rods 1 It is fixed at the intersection point of two horizontal rods 1, and the other end is fixed on the well hole casing 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com