Double-water-tank system air source heat pump water heater

An air source heat pump and water heater technology, applied in heat pumps, fluid heaters, lighting and heating equipment, etc., can solve the problems of reduced stability and reliability, many water pumps, and high installation costs, reducing the working temperature point, improving the COP value, The effect of low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

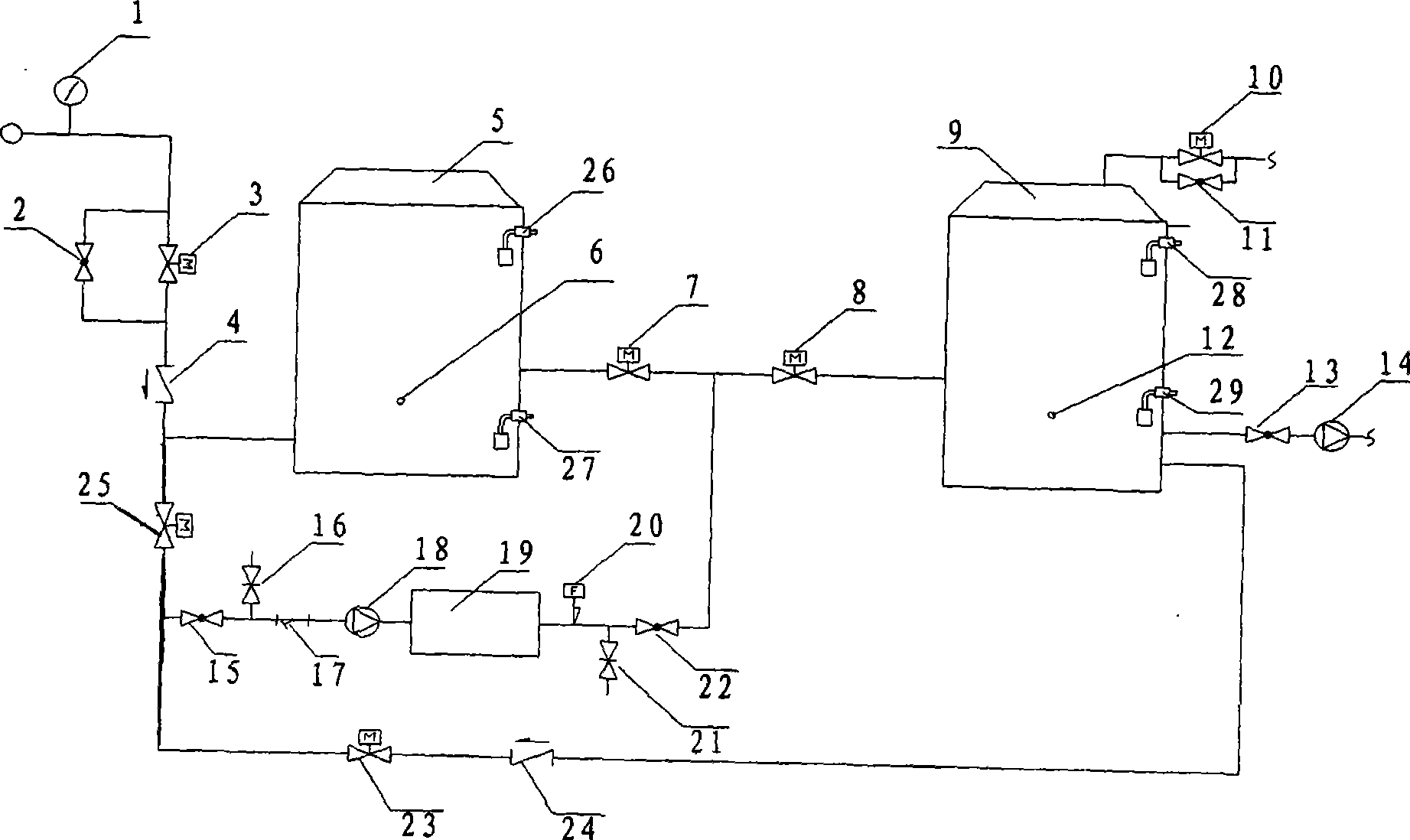

[0009] Below in conjunction with example and accompanying drawing thereof, the present invention is further elaborated.

[0010] see figure 1 , an air source heat pump water heater with a double water tank system, which includes a host 19 containing a refrigeration system, a heating water tank 5, an insulated water tank 9 and a controller, and the upper and lower parts of the heating water tank 5 are respectively equipped with a first high water level switch 26 and a first low water level switch 27. The built-in heating water tank temperature sensor 6, the upper and lower parts of the heat preservation water tank 9 are respectively equipped with a second high water level switch 28 and a second low water level switch 29, a built-in heat preservation water tank temperature sensor 12, a second electromagnetic switch connected in series between the heat preservation water tank 5 and the heat preservation water tank 9 Valve 7 and the third electromagnetic valve 8, the pipeline on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com