Waste water separate collection monitoring method and system in electroplating industrial park

A monitoring system and technology for industrial parks, applied in the field of wastewater classification, collection, monitoring and systems in electroplating industrial parks, can solve problems such as complex wastewater treatment, and achieve the effects of reducing operating costs, facilitating supervision, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

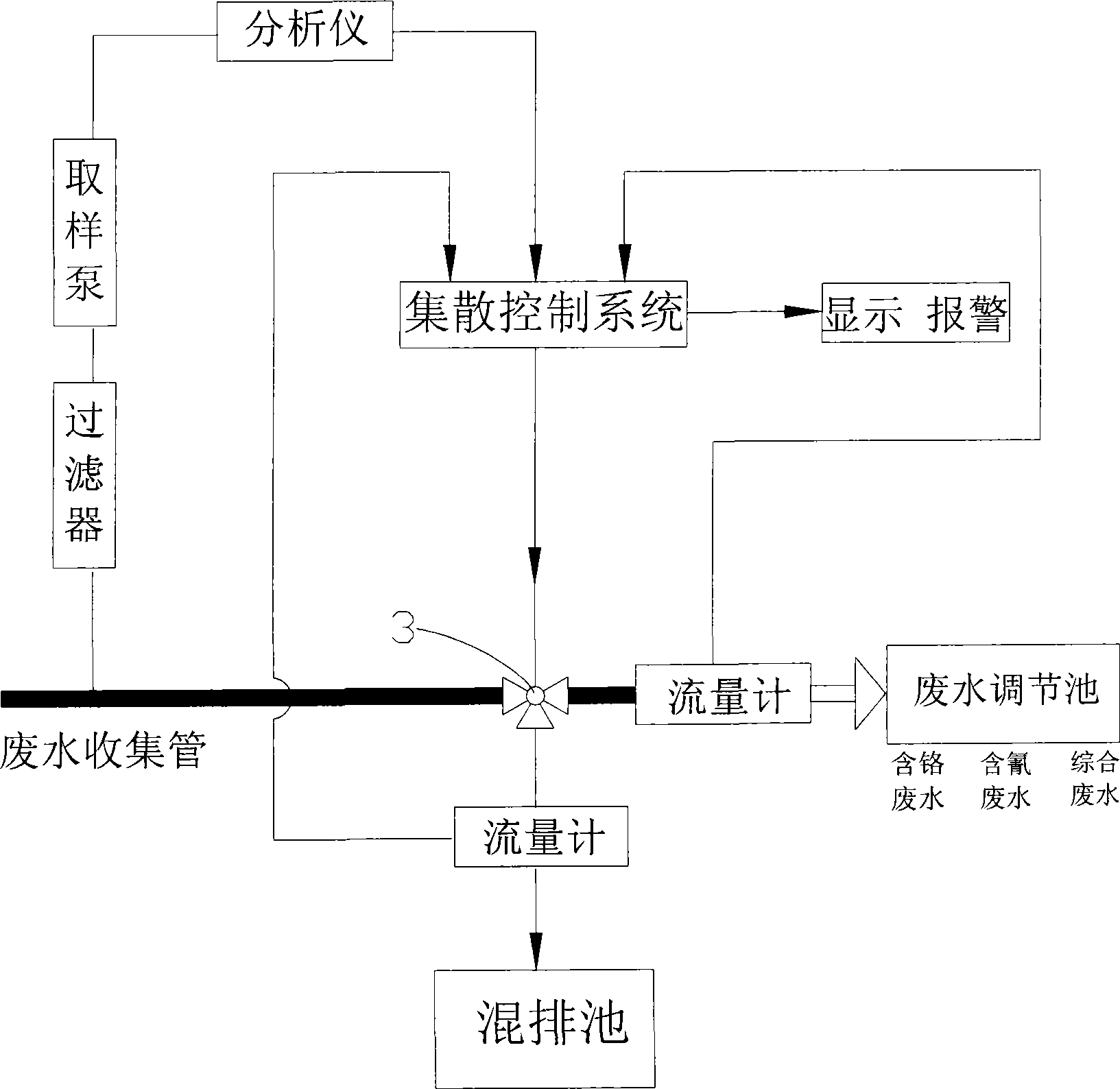

[0028] see Figure 1 to Figure 3 Shown, a kind of electroplating industrial park waste water classification collection monitoring method, comprises the following steps: (1) sampling: take sample from waste water collecting pipe;

[0029] (2) Analysis: analyze and measure the samples taken;

[0030] (3) Comparison: compare the measured value obtained by the analysis and measurement with the preset value;

[0031] (4) Control: According to the comparison result in step (3), when the measured value is less than or equal to the predetermined value, then the waste water is sent to the cyanide-containing waste water regulating pond or the chromium-containing waste water regulating pond or the comprehensive waste water pond respectively, when the measured value When it is greater than the predetermined value, the waste water is sent to the mixing tank.

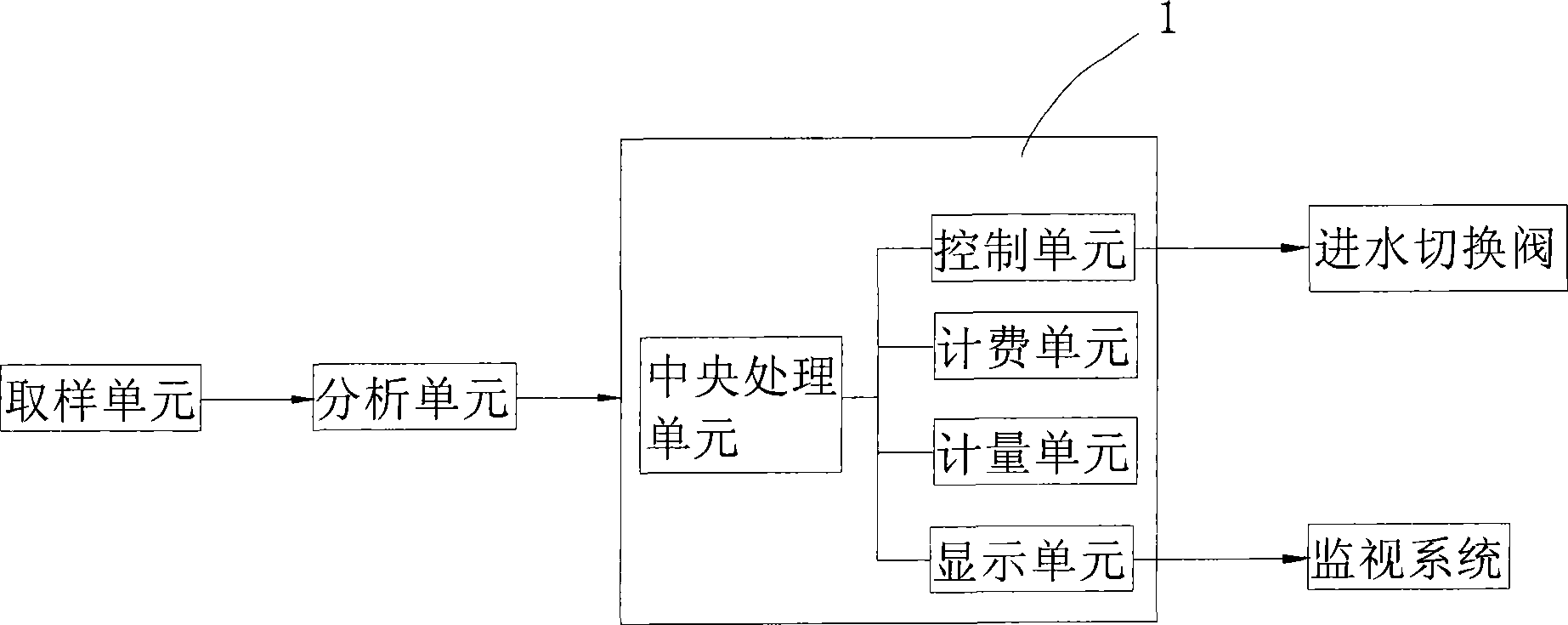

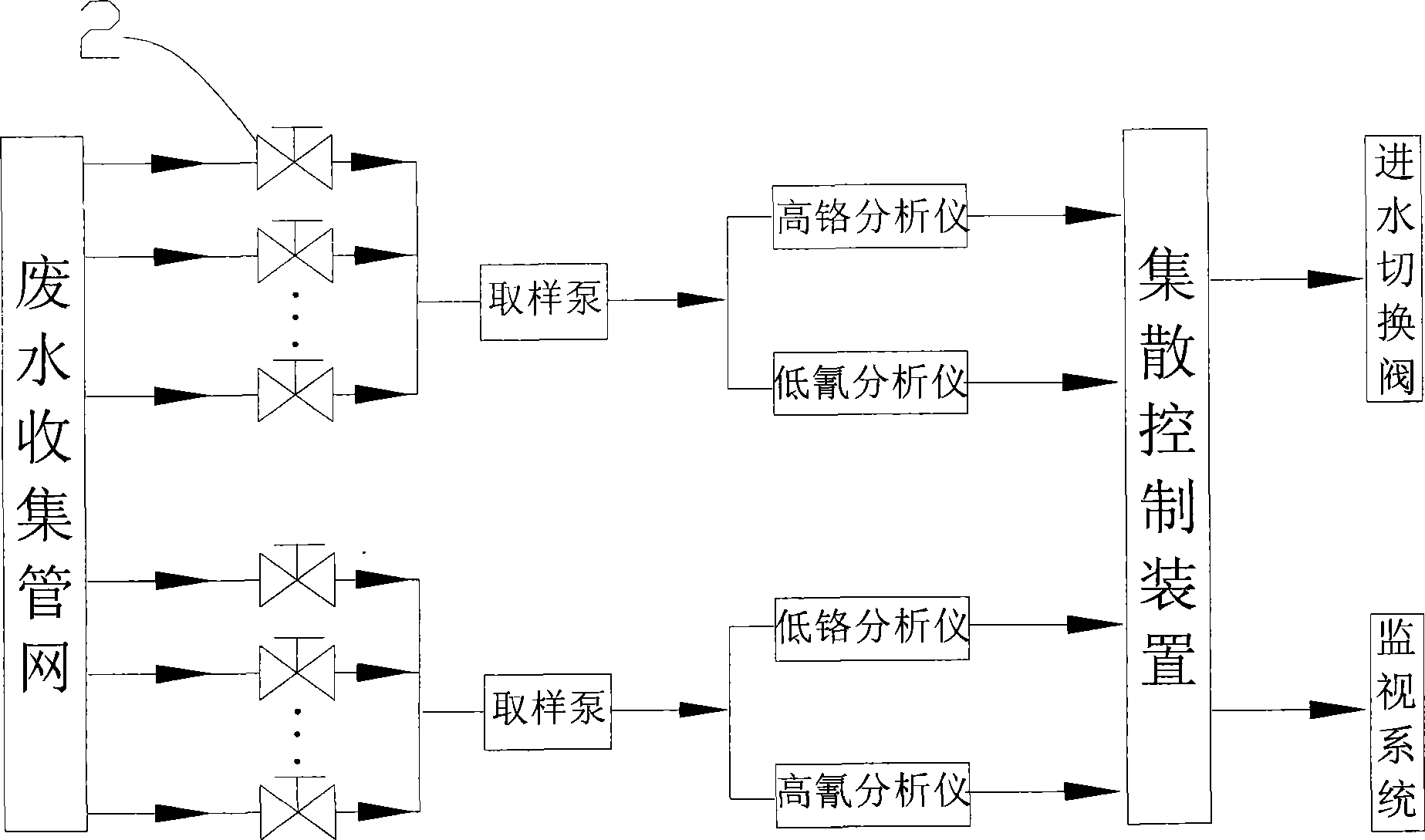

[0032] This embodiment also has a monitoring system applied to the electroplating industrial park wastewater classification colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com