DC bus bar connection construction for large power three-phase inverter

A three-phase inverter, DC bus technology, applied in the output power conversion device, bus/circuit layout, electrical components and other directions, can solve the problem of not taking into account the group installation of capacitors and improve the utilization of capacitors, etc., to achieve convenient assembly and The effect of disassembly and maintenance, improving utilization, and reducing ripple current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

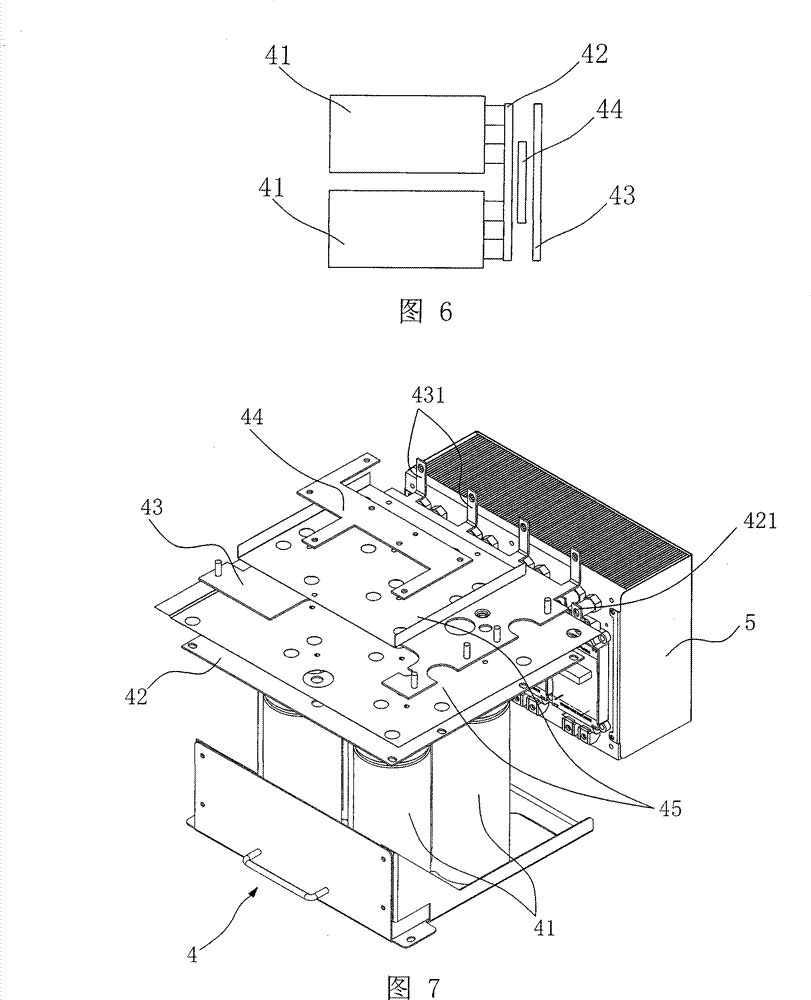

[0031] Figures 5 to 9 show a preferred embodiment of the present invention.

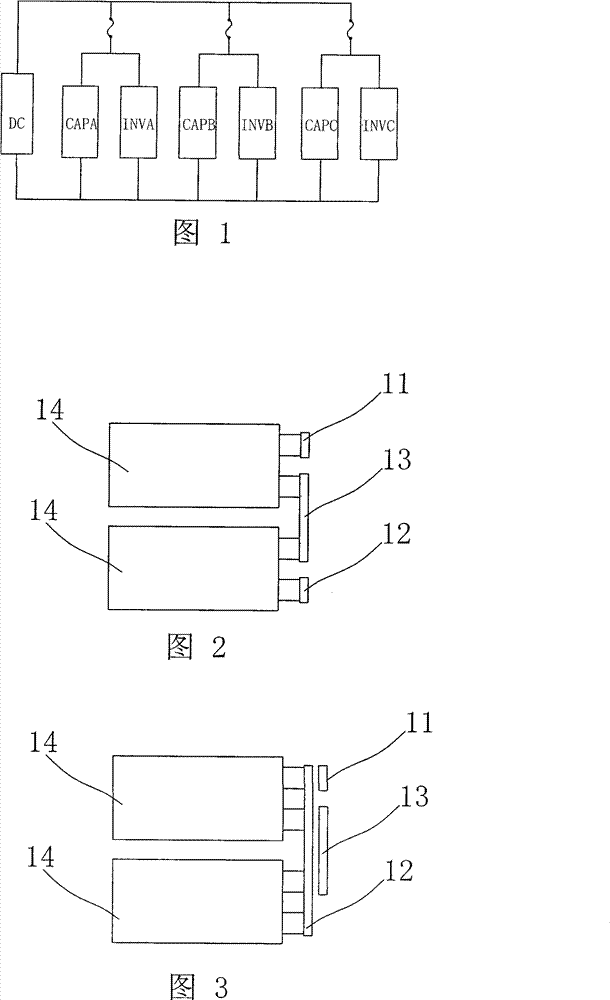

[0032] Please refer to Fig. 5, in this embodiment, the bus connection of the high-power three-phase inverter includes three capacitor modules (CAPA, CAPB, CAPC) 2, 4, 6 and three inverter switch tube modules (INVA , INVB, INVC) 3, 5, 7, each capacitor module is connected in parallel with an inverter switching tube module, and the capacitor module and the inverter switching tube module are connected in parallel to the DC power supply (DC) 1 . A fuse 8 is provided between the capacitor module, the inverter switch tube module and the DC power supply (DC) 1 after parallel connection.

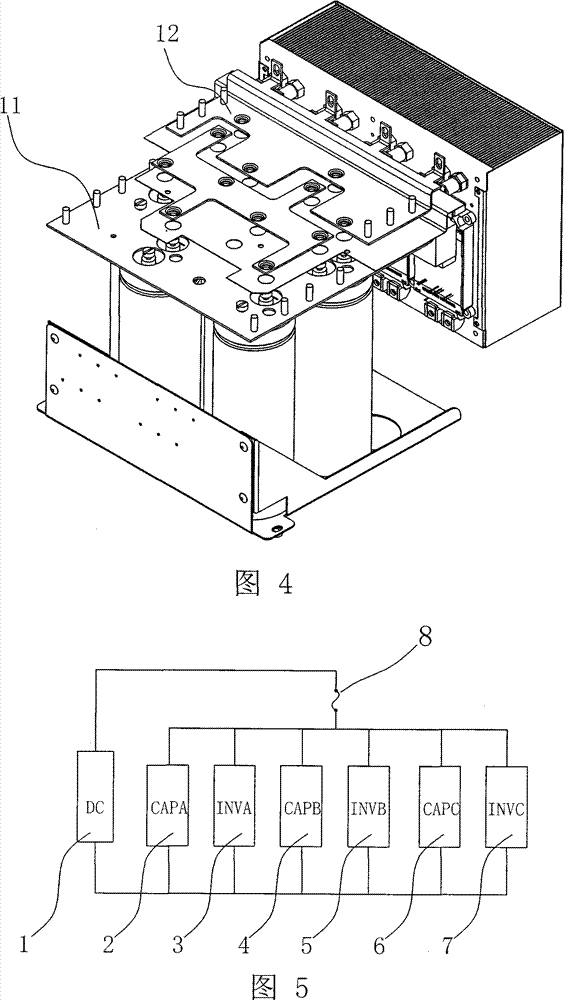

[0033] Referring to Fig. 6 and Fig. 7, in this embodiment, the capacitor module 4 is composed of eight electrolytic capacitors 41 connected by copper bars, and the connected copper bars include a positive electrode copper bar 42, a negative electrode copper bar 43, and an intermediate connecting copper bar 44 , the three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com