Plumbago melting furnace

A melting furnace and graphite technology, applied in the field of melting furnaces, can solve the problems of low production efficiency, short service life of carbon steel furnaces, poor uniformity of material mixing and ejection, etc., and achieve the effects of reducing processing time, increasing service life and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

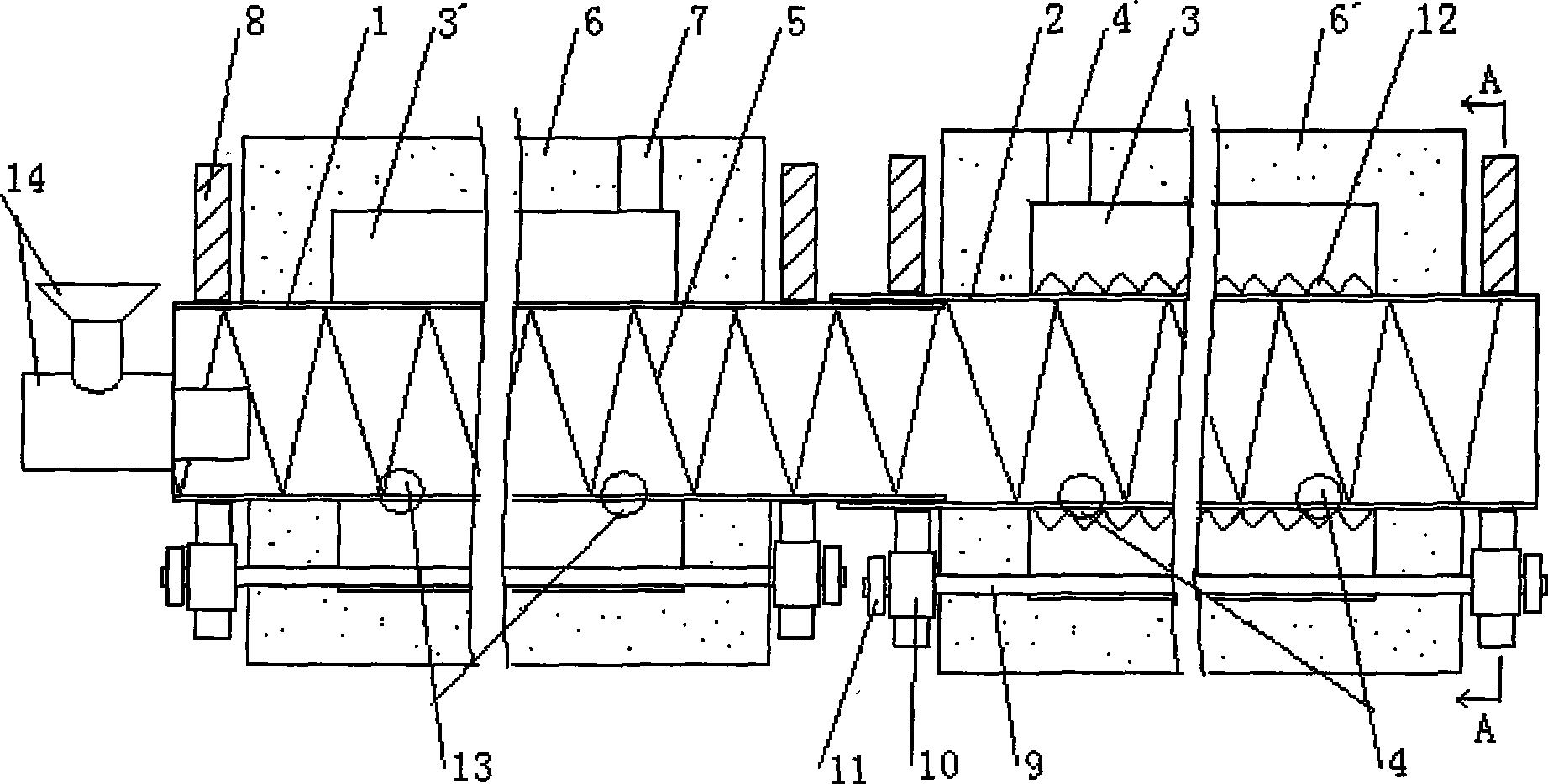

[0018] like figure 1 As shown, the present invention includes a transmission device, a high-temperature chamber, and a stirring and ejecting device for materials in the high-temperature chamber, as well as an insulating layer 6 of the high-temperature chamber, and a heating chamber 3' between the two.

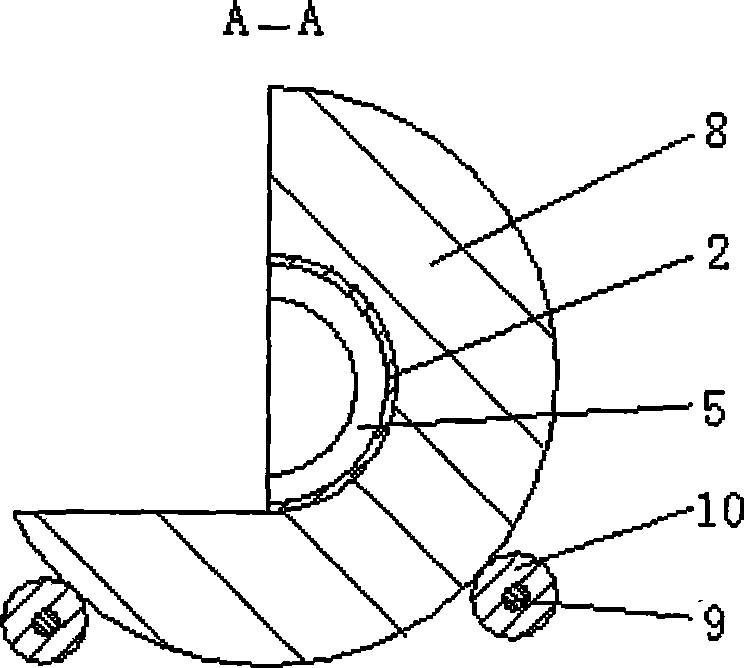

[0019] still as figure 1 As shown, the high temperature chamber 1 is made of stainless steel, a metal material resistant to high temperature and alkali corrosion. The material stirring and pushing device is that the inner wall of the high temperature chamber 1 is provided with spiral fins 5, and the horizontal angle of the spiral fins 5 is selected as 50°. The spiral fin 5 is made of the same material as the high-temperature chamber 1 , and the spiral fin 5 is processed into a strip-shaped sheet, and one side thereof is welded to the inner wall of the high-temperature chamber 1 . The transmission shaft 9 in the transmission device passes through the insulation layer 6 of the ...

Embodiment 2

[0021] like figure 1 As shown, the high temperature chamber 1 is connected with the cooling chamber 2, the inner diameter of the high temperature chamber 1 is slightly smaller than the inner diameter of the cooling chamber 2, and its discharge end is inserted into the feeding end of the cooling chamber 2, and the two are connected by a clearance fit. The cooling chamber 2 is provided with a transmission device consistent with the high-temperature chamber 1, and the cooling chamber 2 is also provided with an insulation layer 6'; the transmission shaft 9 in the transmission device passes through the insulation layer 6' of the cooling chamber 2 at both ends, and adopts The bearing is movably connected on the frame (not shown in the figure); the transmission wheel 10 is fixedly connected to the two ends of the transmission shaft 9 respectively, and the end of the transmission shaft 9 outside the transmission wheel 10 is respectively fixedly connected with a power input wheel 11, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com