Integral anaerobic dynamic membrane bioreactor and method of operation

An anaerobic membrane biological and dynamic membrane technology, applied in the field of water treatment, can solve the problems of high energy consumption of circulating pumps, difficult to clean, and high membrane cost, and achieve the effects of reducing operating costs, increasing membrane flux, and resisting impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

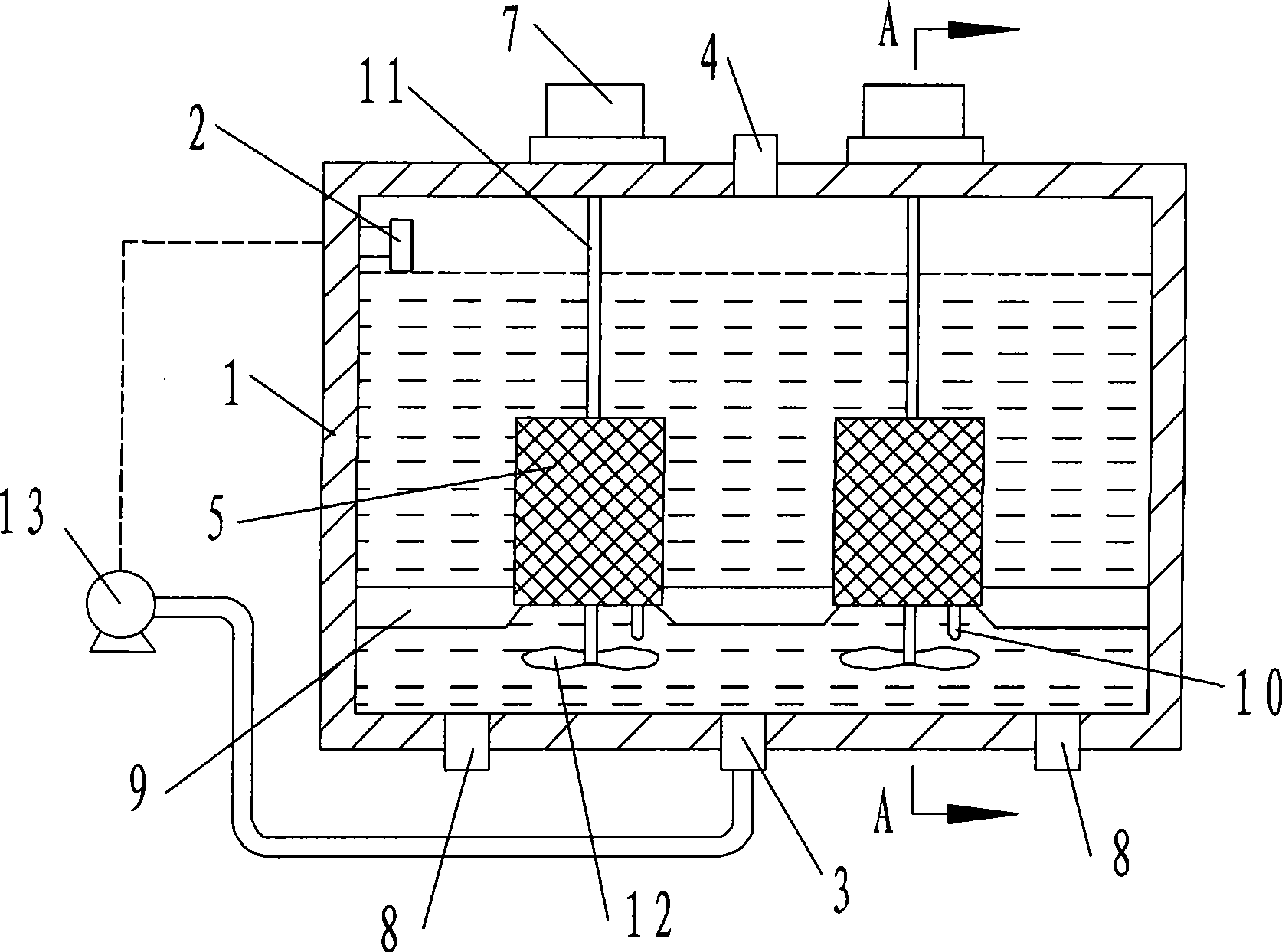

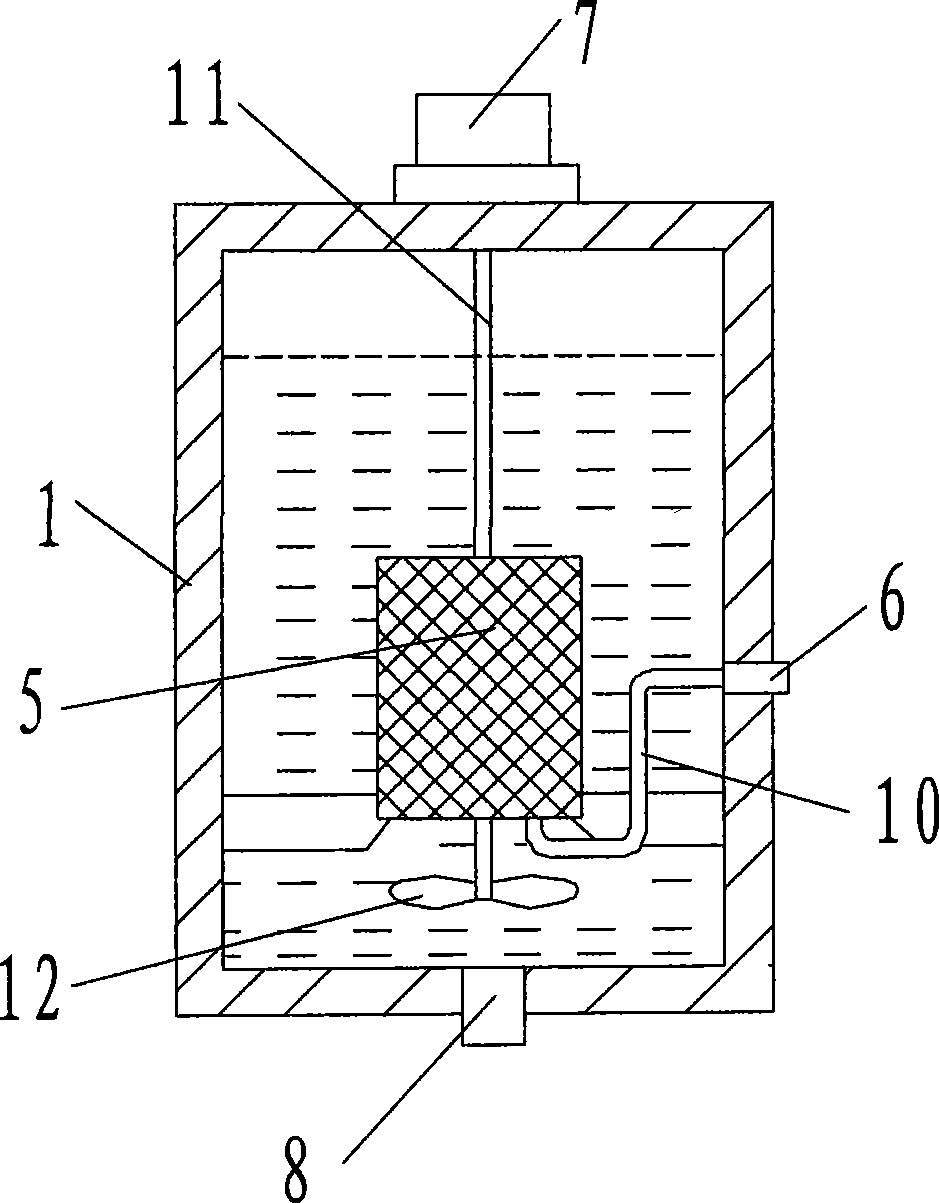

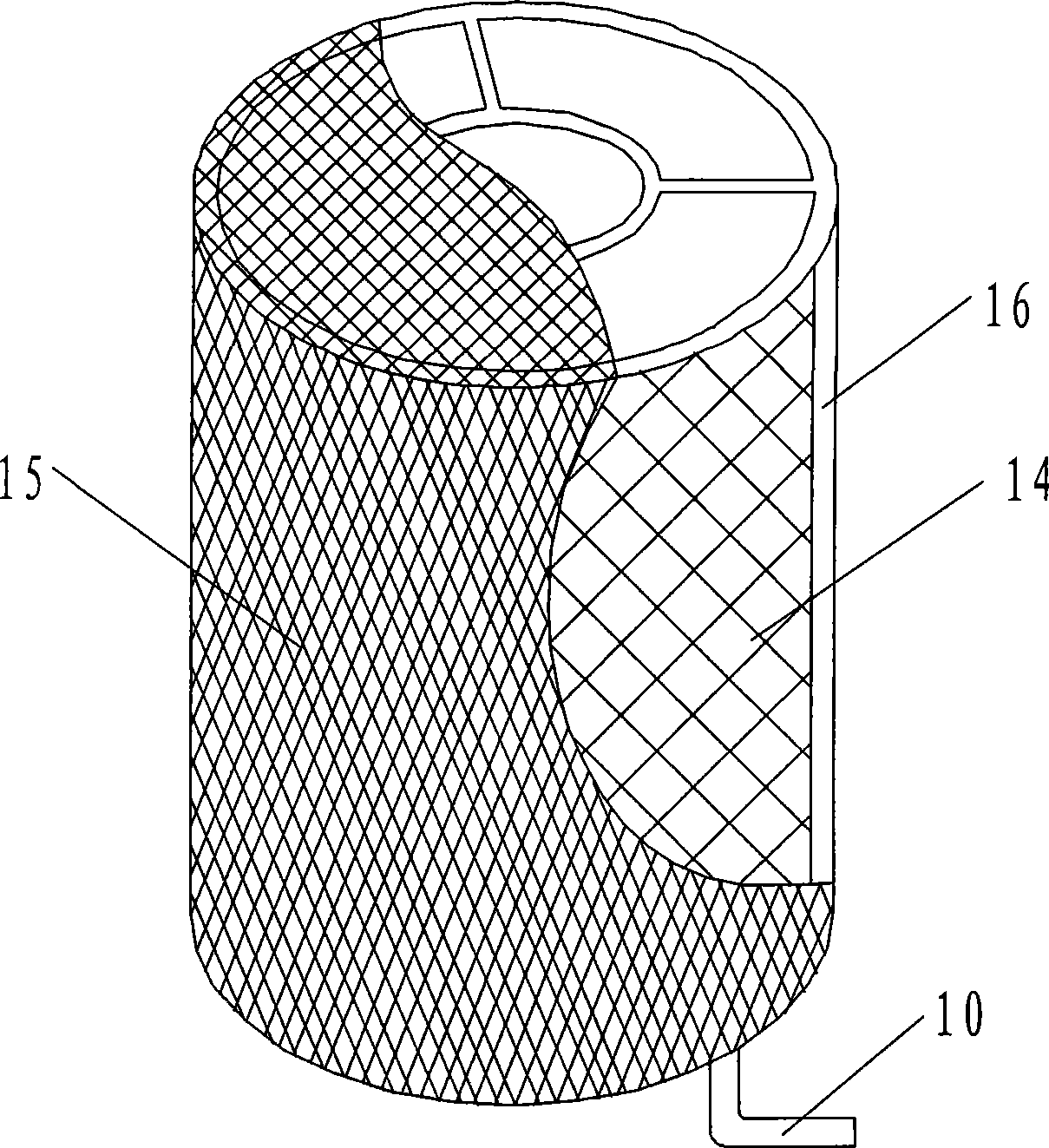

[0015] Such as figure 1 As shown, the integrated anaerobic membrane bioreactor provided by the present invention is mainly composed of a main body 1 , a dynamic membrane module 5 and a stirring device 7 . The main body 1 is of a sealed structure, with an exhaust port 4 on the top, a water outlet 6 on the side, and a water inlet 3 and a mud discharge port 8 on the bottom. Two dynamic membrane modules 5 are installed in the main body 1 (the number of dynamic membrane modules 5 is determined according to the size of the main body 1 and the actual situation), and each dynamic membrane module 5 is supported and installed on the main body 1 by three ribs 9 at 120° to each other. middle. The structure of the dynamic membrane module 5 is as figure 2 As shown, the polyurethane activated carbon filter screen 15 is wrapped around the cylindrical skeleton 16, and the metal mesh 14 is built in the skeleton 6, so as to avoid the surface depression of the membrane module caused by the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com