System and method for catalyzing hydrocarbon for recombinant production of high-quality gasoline

A technology of heavy gasoline and catalytic hydrocarbons, which is applied in the direction of gasoline stabilization, refining hydrocarbon oil, and aromatics hydrorefining, etc., which can solve the problems of high operating costs, high olefin content, and low octane number, and achieve low cost and low olefin content. Low, low sulfur effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

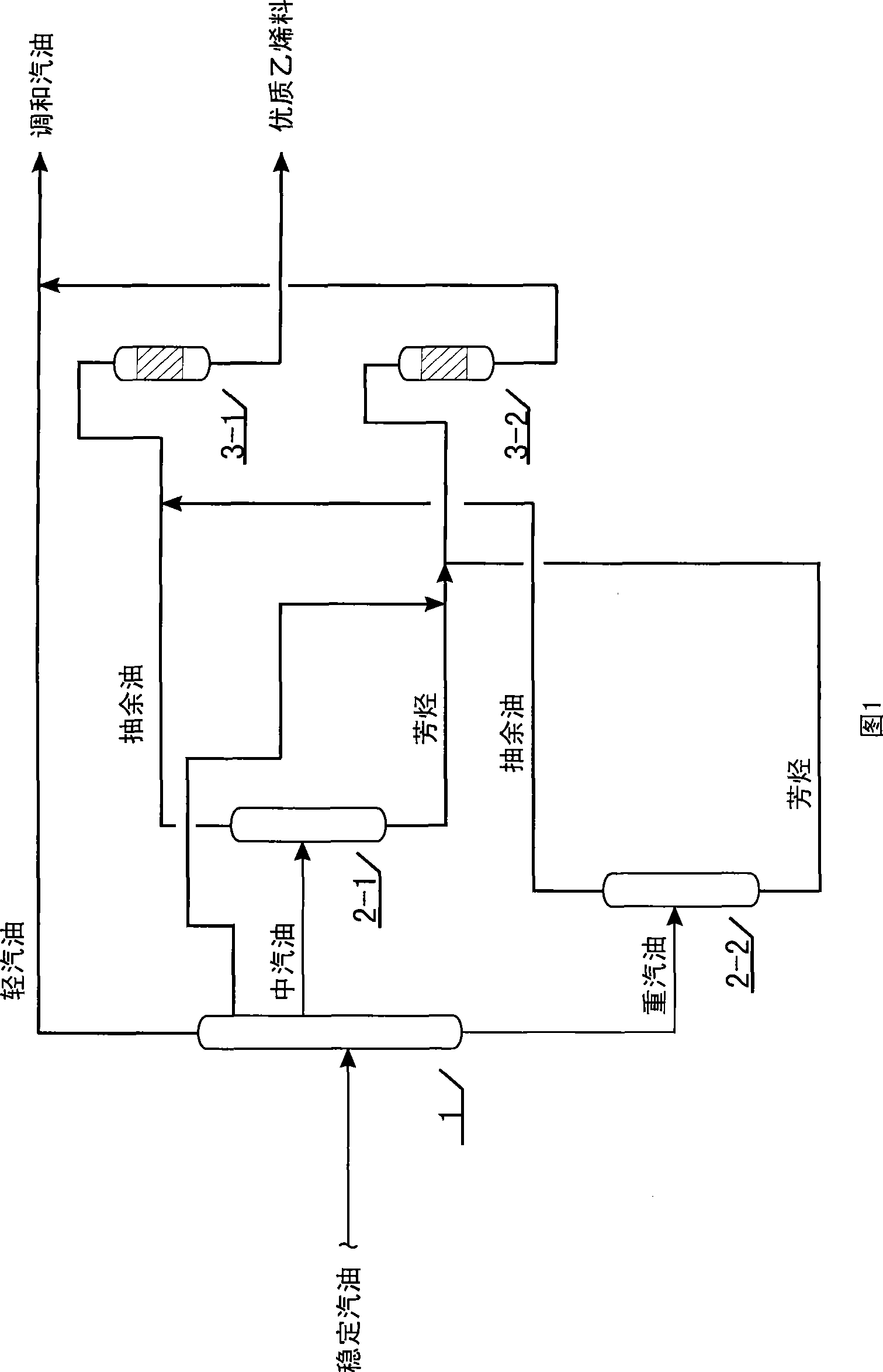

[0034] As shown in Figure 1, the distillation range is 30-205°C, the sulfur content is 300ppm, the mercaptan content is 8.0ppm, the olefin content is 40% (v), the diene content is 1% (v), and the aromatic hydrocarbon content is 19%(v), octane number (RON) 91, density 728 kg / m 3The stable gasoline (catalytic gasoline) is cut and fractionated in distillation tower 1 with a flow rate of 100,000 tons / year. The temperature at the top of distillation tower 1 is 67°C, the temperature at the bottom of the tower is 186°C, and the distillation range of light-medium gasoline is 65°C. -90°C; the distillation range of medium gasoline is 90-160°C. Tower top pressure is 0.2MPa (absolute), tower bottom pressure is 0.25MPa (absolute), fractionation obtains light gasoline, light-medium gasoline, medium gasoline and heavy gasoline respectively, and described light gasoline (distillation range is 30-65 ℃) Steam through the upper part of the distillation tower 1, and its steaming capacity is 20,0...

Embodiment 2

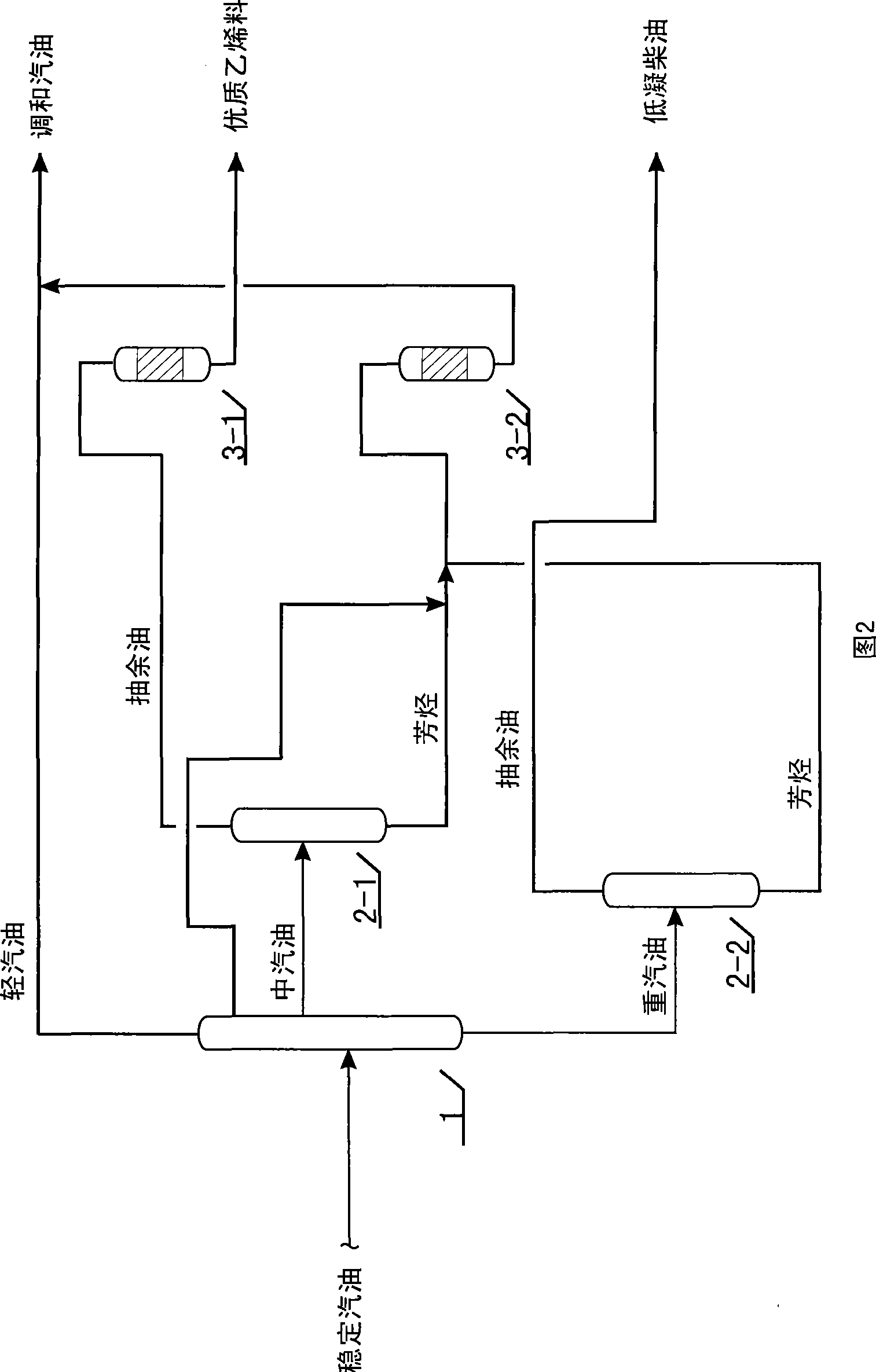

[0052] As shown in Figure 2, the distillation range is 30-205°C, the sulfur content is 300ppm, the mercaptan content is 8.0ppm, the olefin content is 40% (v), the diene content is 1% (v), and the aromatic hydrocarbon content is 19%(v), octane number (RON) 91, density 728 kg / m 3 The stable gasoline is cut and fractionated in distillation tower 1 with a flow rate of 100,000 tons / year. The temperature at the top of distillation tower 1 is 67°C, the temperature at the bottom of the tower is 186°C, and the distillation range of light-medium gasoline is 65-90°C; The distillation range of medium gasoline is 90-160°C. Tower top pressure is 0.2MPa (absolute), tower bottom pressure is 0.25MPa (absolute), fractionation obtains light gasoline, light-medium gasoline, medium gasoline and heavy gasoline respectively, and described light gasoline (distillation range is 30-65 ℃) Steam through the upper part of the distillation tower 1, and its steaming capacity is 20,000 tons / year; the middle...

Embodiment 3

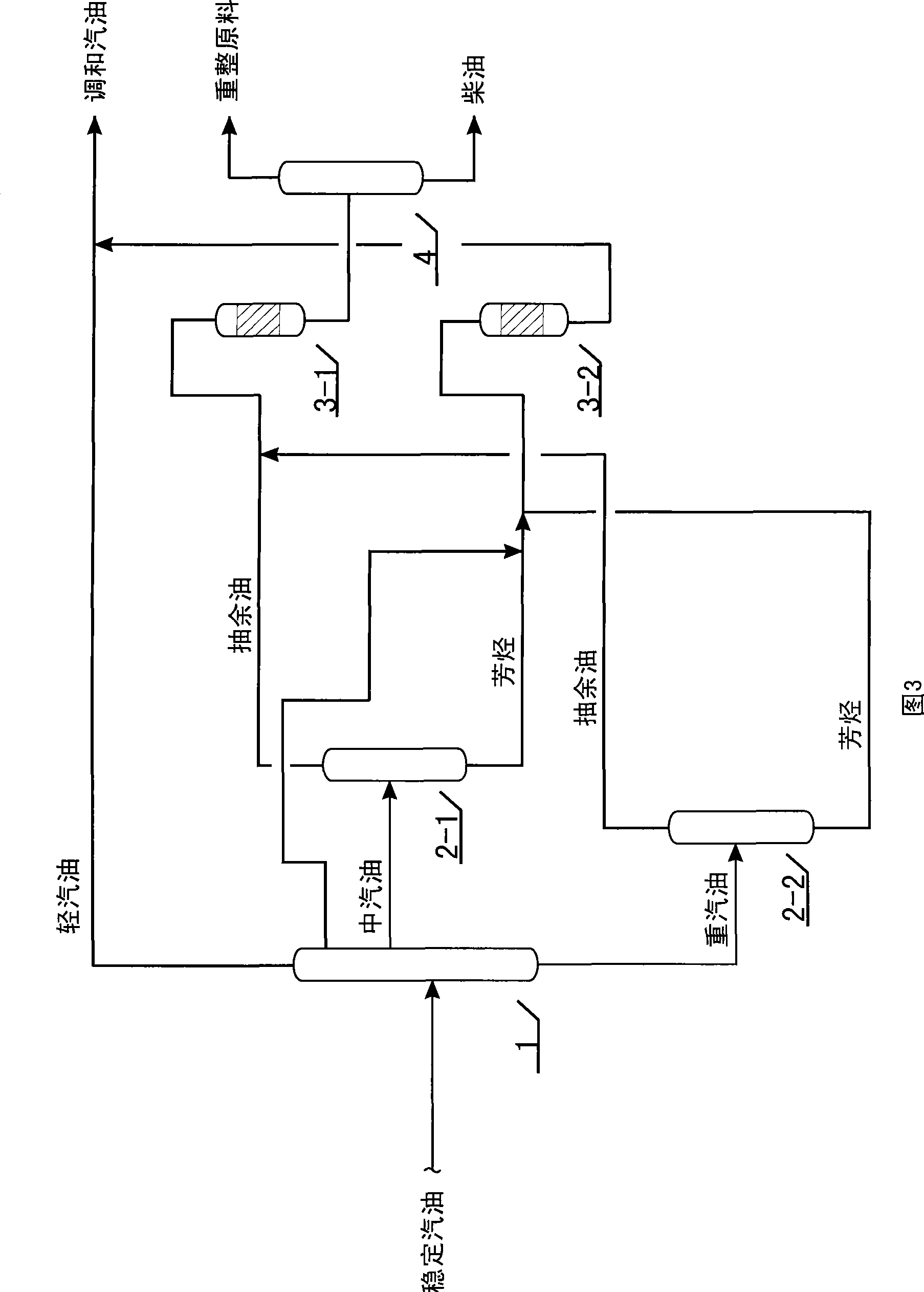

[0057] As shown in Figure 3, the distillation range is 30-205 ° C, the sulfur content is 100 ppm, the mercaptan content is 5.0 ppm, the olefin content is 30% (v), the diene content is 0.1% (v), and the aromatic content is 15%(v), octane number (RON) 89, density 728 kg / m 3The stable gasoline (catalytic gasoline) is cut and fractionated in the distillation tower 1 with a flow rate of 100,000 tons / year. The temperature at the top of the distillation tower 1 is 68°C, the temperature at the bottom of the tower is 188°C, and the distillation range of light-medium gasoline is 65°C. -90°C; the distillation range of medium gasoline is 90-160°C. Tower top pressure is 0.2MPa (absolute), tower bottom pressure is 0.25MPa (absolute), fractionation obtains light gasoline, light-medium gasoline, medium gasoline and heavy gasoline respectively, and described light gasoline (distillation range is 30-65 ℃) Steam through the upper part of the distillation tower 1, and its steaming capacity is 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com