Treatment process for industrial wastewater

A technology for treating process and industrial wastewater, applied in multi-stage water treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc. It can solve problems such as operator poisoning, sulfur easily exceeding the standard, and pollute the environment, so as to reduce the number of employees. Labor intensity, saving raw materials and labor costs, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

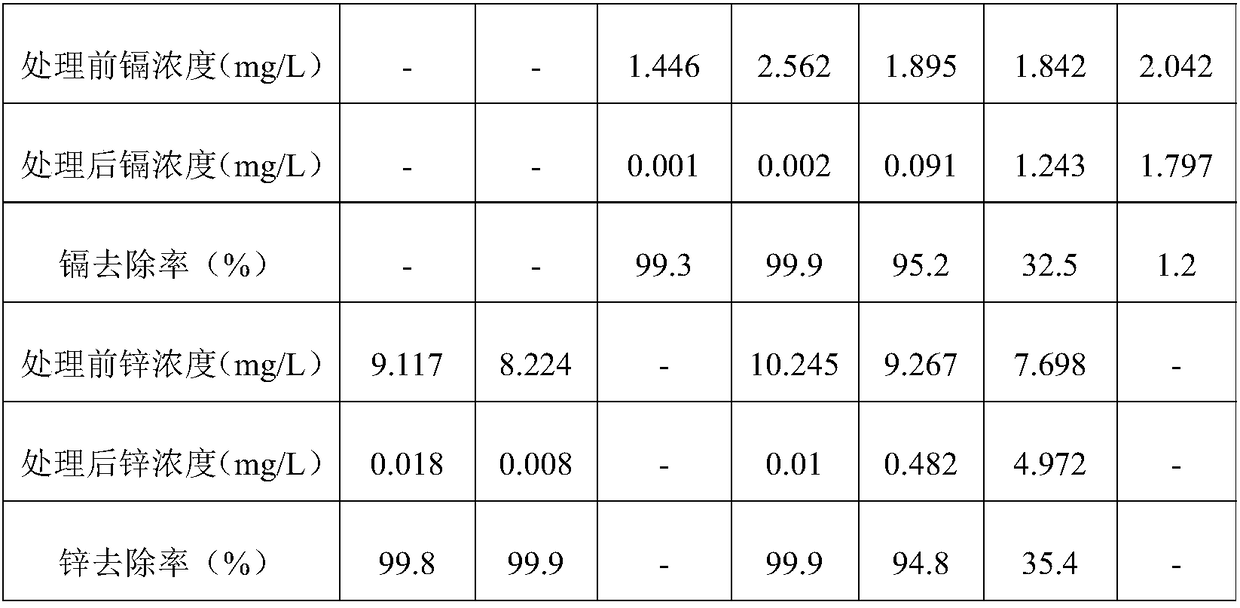

Embodiment 1

[0016] This embodiment provides an industrial wastewater treatment process, including: discharging the wastewater through a regulating tank, a neutralization tank, an aeration oxidation tank, a coagulation reaction tank, a sedimentation tank, a filter tank, and a pH callback tank in sequence: wherein, the detection If zinc is contained in the waste water, lime with a particle size of 70 mesh after slurry is added to the coagulation reaction tank to adjust the pH of the reaction solution to 7; sulfuric acid is used to adjust the filtrate to pH 6 in the pH callback tank.

Embodiment 2

[0018] This embodiment provides an industrial wastewater treatment process, including: discharging the wastewater through a regulating tank, a neutralization tank, an aeration oxidation tank, a coagulation reaction tank, a sedimentation tank, a filter tank, and a pH callback tank in sequence: wherein, the detection If zinc is contained in the waste water, slurryed lime with a particle size of 90 mesh is added to the coagulation reaction tank to adjust the pH of the reaction solution to 8; sulfuric acid is used to adjust the filtrate to pH 9 in the pH callback tank.

Embodiment 3

[0020] This embodiment provides an industrial wastewater treatment process, including: discharging the wastewater through a regulating tank, a neutralization tank, an aeration oxidation tank, a coagulation reaction tank, a sedimentation tank, a filter tank, and a pH callback tank in sequence: wherein, the detection If cadmium is contained in the waste water, lime with a particle size of 80 mesh after slurry is added to the coagulation reaction tank to adjust the pH of the reaction solution to 9; sulfuric acid is used to adjust the filtrate to pH 7 in the pH callback tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com