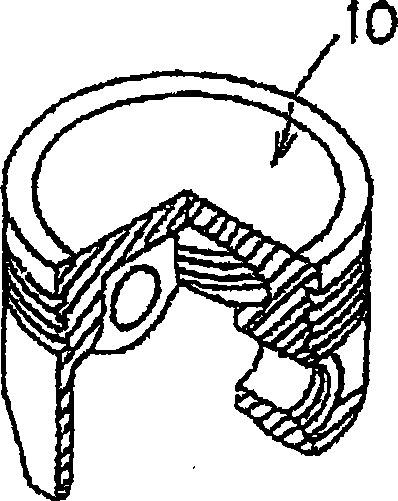

Piston ring

A technology for piston rings and base layers, applied in the field of piston rings, can solve the problems of surface coating film wear and peeling, loss of lubricating ability, wear of piston ring grooves, etc., and achieve the effect of preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

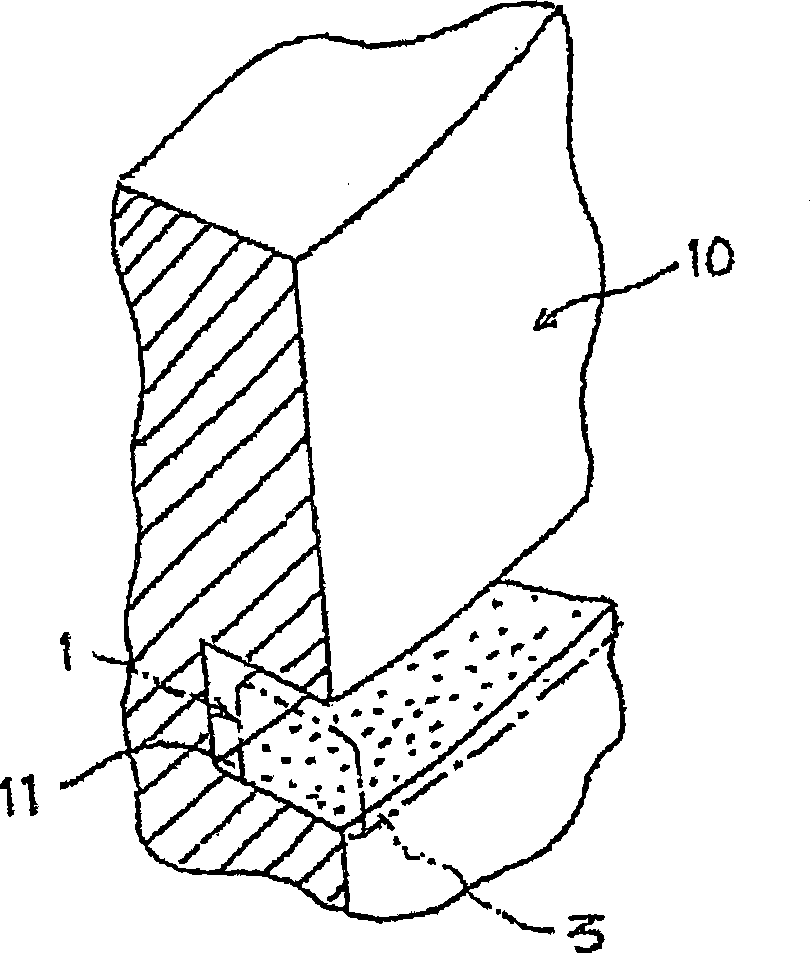

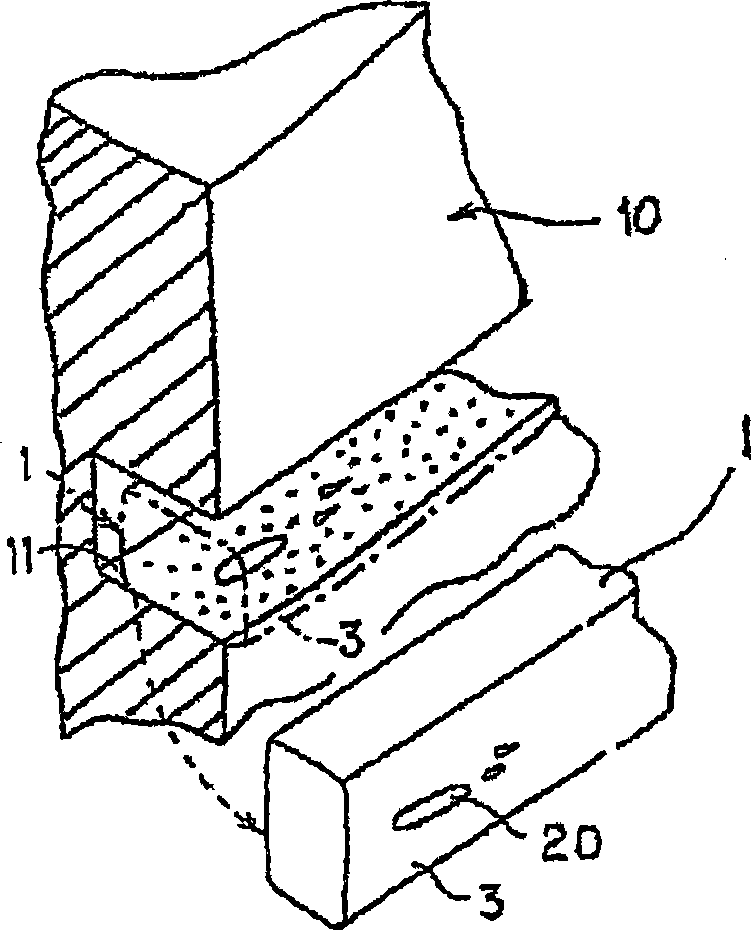

[0041] Refer below Image 6 and FIG. 7 present a first embodiment of a piston ring according to the invention.

[0042] refer to Image 6 , the piston ring 60 of this embodiment has a piston ring body 61 and on at least one of the upper surface and the lower surface of the piston ring body 61 ( Image 6 In is the surface coating film 62 formed on both the upper surface and the lower surface). The surface coating film 62 is provided on the portion of the piston ring body 61 farthest from the sliding surface side, and is composed of an outermost surface layer 64 including a heat-resistant resin 65 and a base (innermost) layer 63 . The metal powder 67 contained in the heat-resistant resin 65 , the base layer 63 is disposed closest to the piston ring body 61 and is composed of the heat-resistant resin 66 .

[0043] The material of the piston ring body 61 of the present invention is not particularly limited, and various materials can be used. For example, steel (steel material)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com