LED back light source structure

An LED backlight and LED chip technology, applied in the fields of optics and image processing, can solve the problems of increased energy consumption and heat, and achieve the effects of preventing deformation, improving light efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

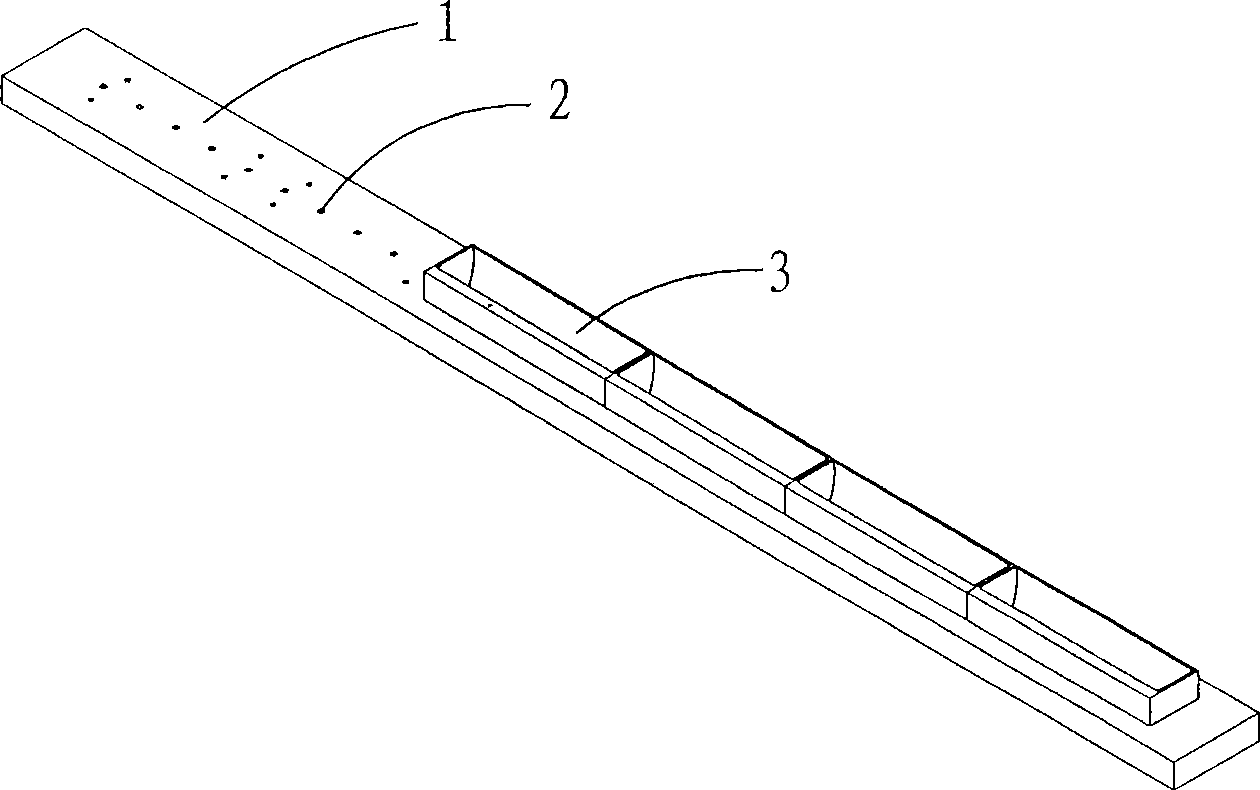

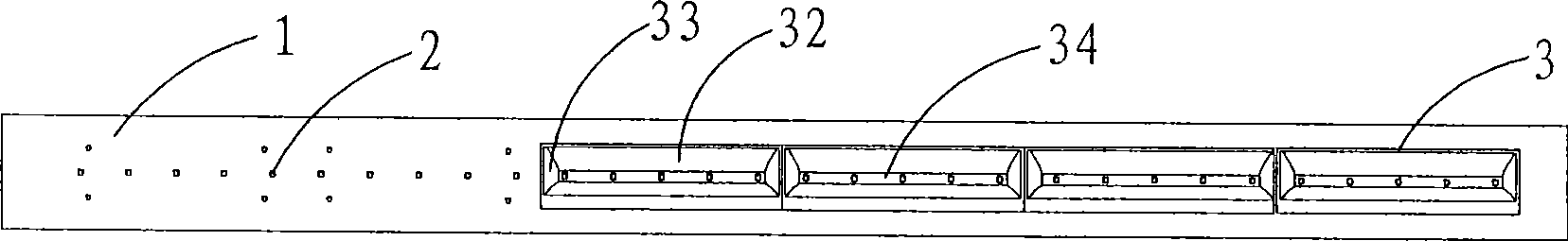

[0022] Such as Figure 1 to Figure 3 As shown, the LED backlight structure of the present invention includes a substrate 1 , a plurality of LED chips 2 and a plurality of reflective modules 3 .

[0023] The substrate 1 is a strip-shaped linear plate, and the LED chips 2 are arranged on the substrate 1 in a line;

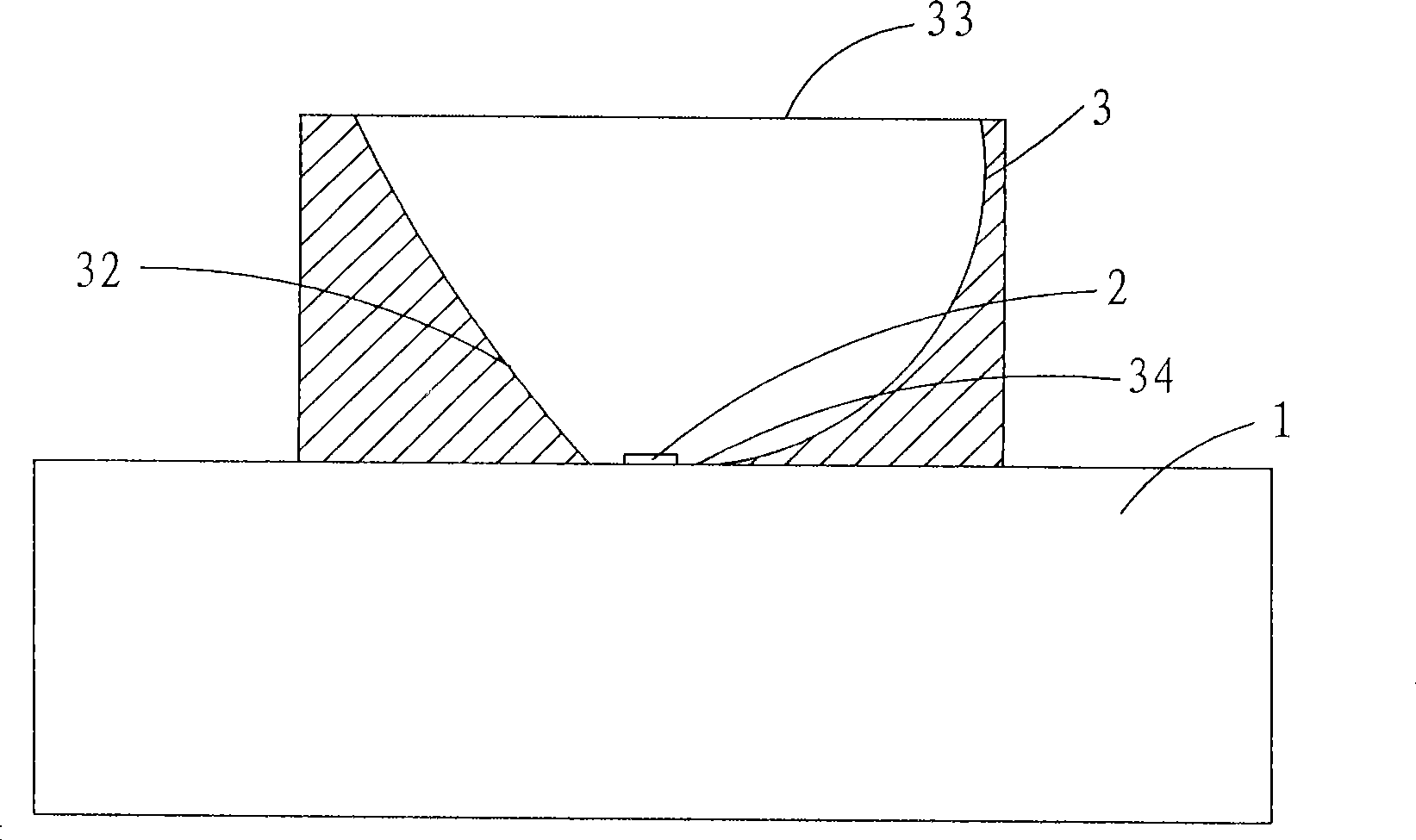

[0024] Cooperate Figure 4 , 5 , 6, and 7, the reflective module 3 is a rectangular block formed in response to the size of the substrate 1, its upper end is an opening 31, and its front and rear inner surfaces are arc-shaped concaves from the upper end to the bottom to form an asymmetric curved surface 32 , and the left and right inner surfaces are also arc-shaped and concave from the upper end to the bottom to form an asymmetric curved surface 33, and the curvature of the asymmetric curved surfaces 32, 33 is set in response to the length and width of the light guide plate 4; A through linear groove 34 is formed below, and the linear groove 34 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com