High-efficiency easy-cleaning sullage heat exchanger

An easy-to-clean, heat-exchanger technology, which is applied in the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of heavy cleaning workload, high investment and maintenance costs, and achieve faster technological progress and better Excellent heat exchange effect and application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

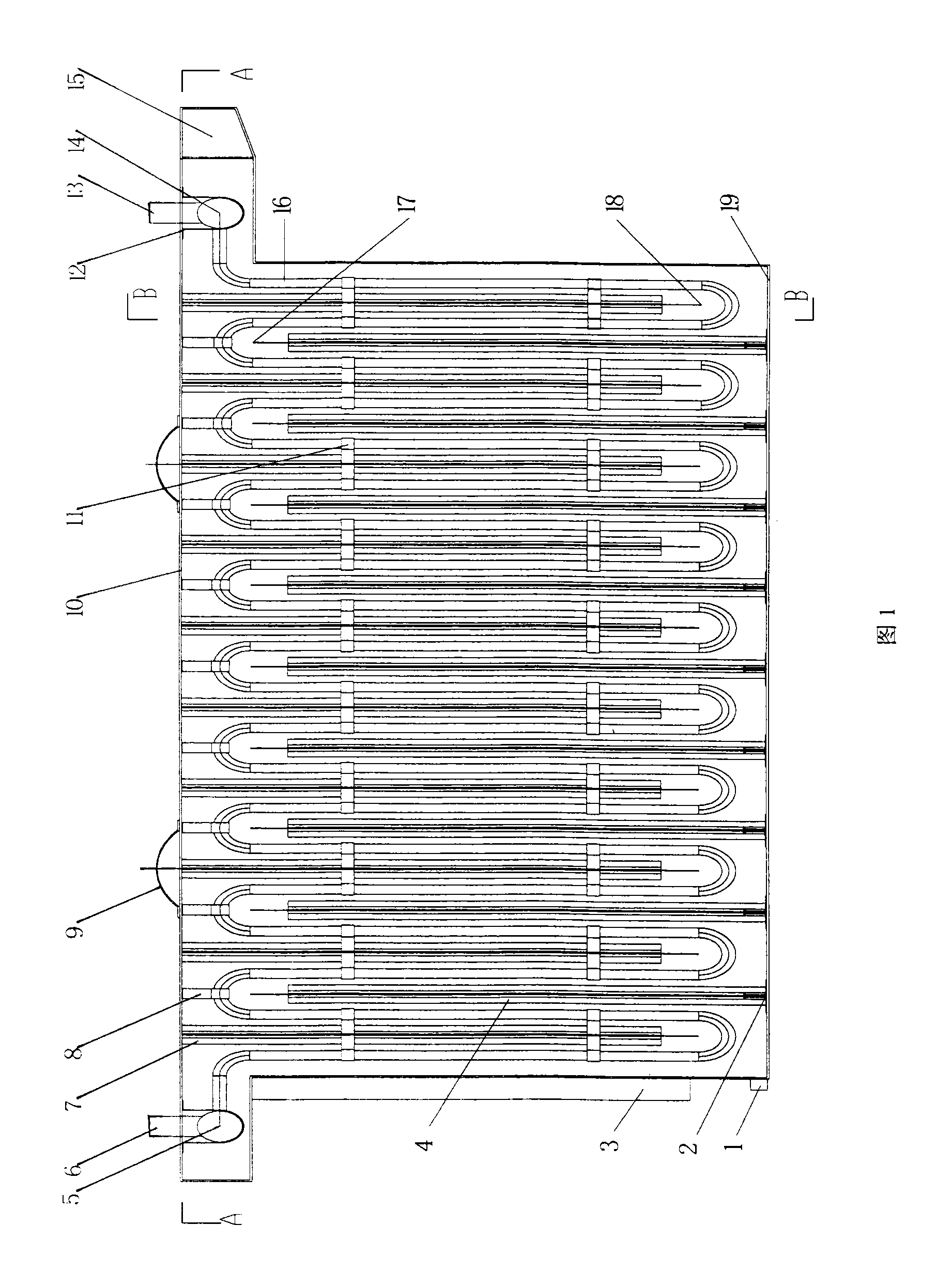

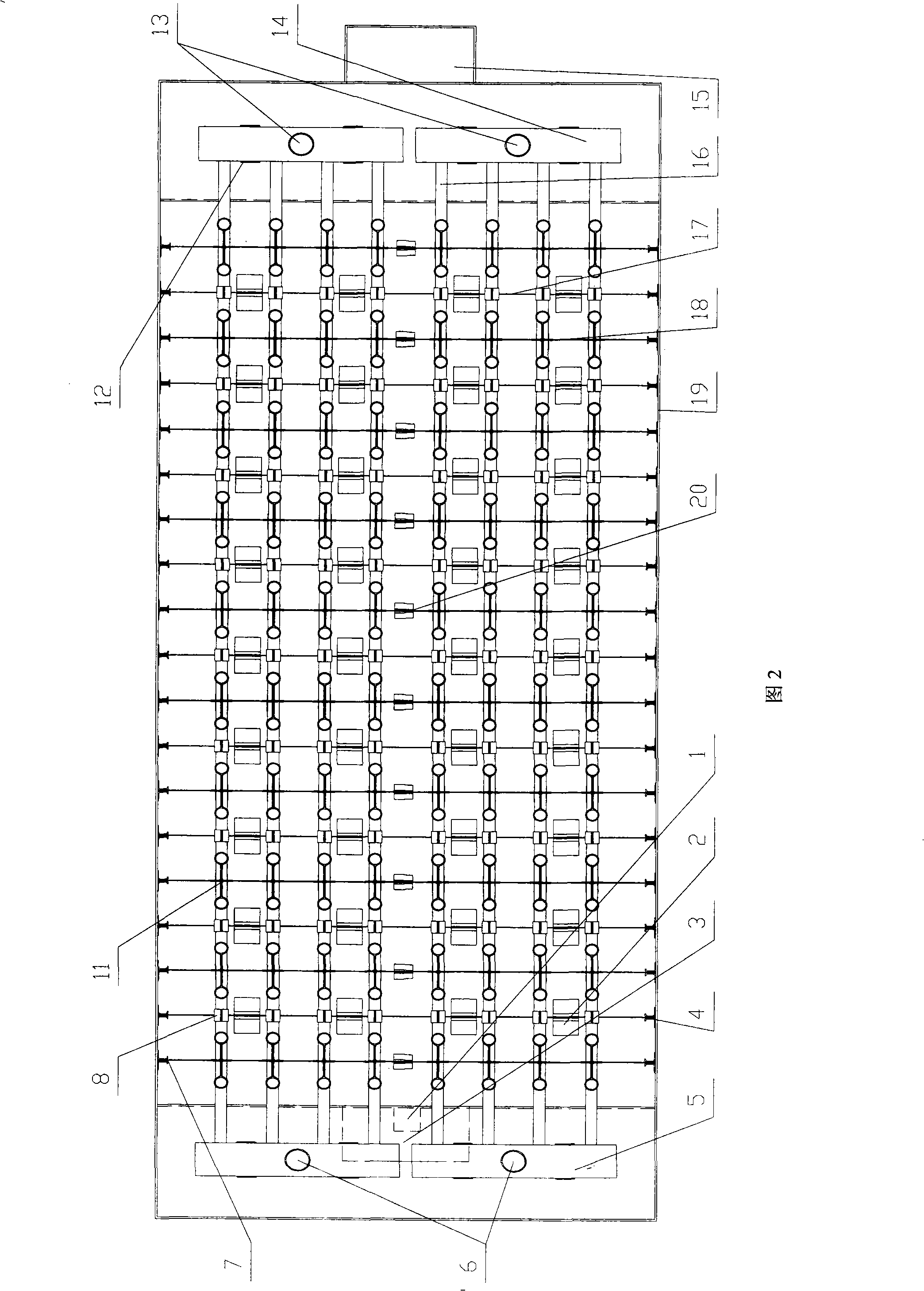

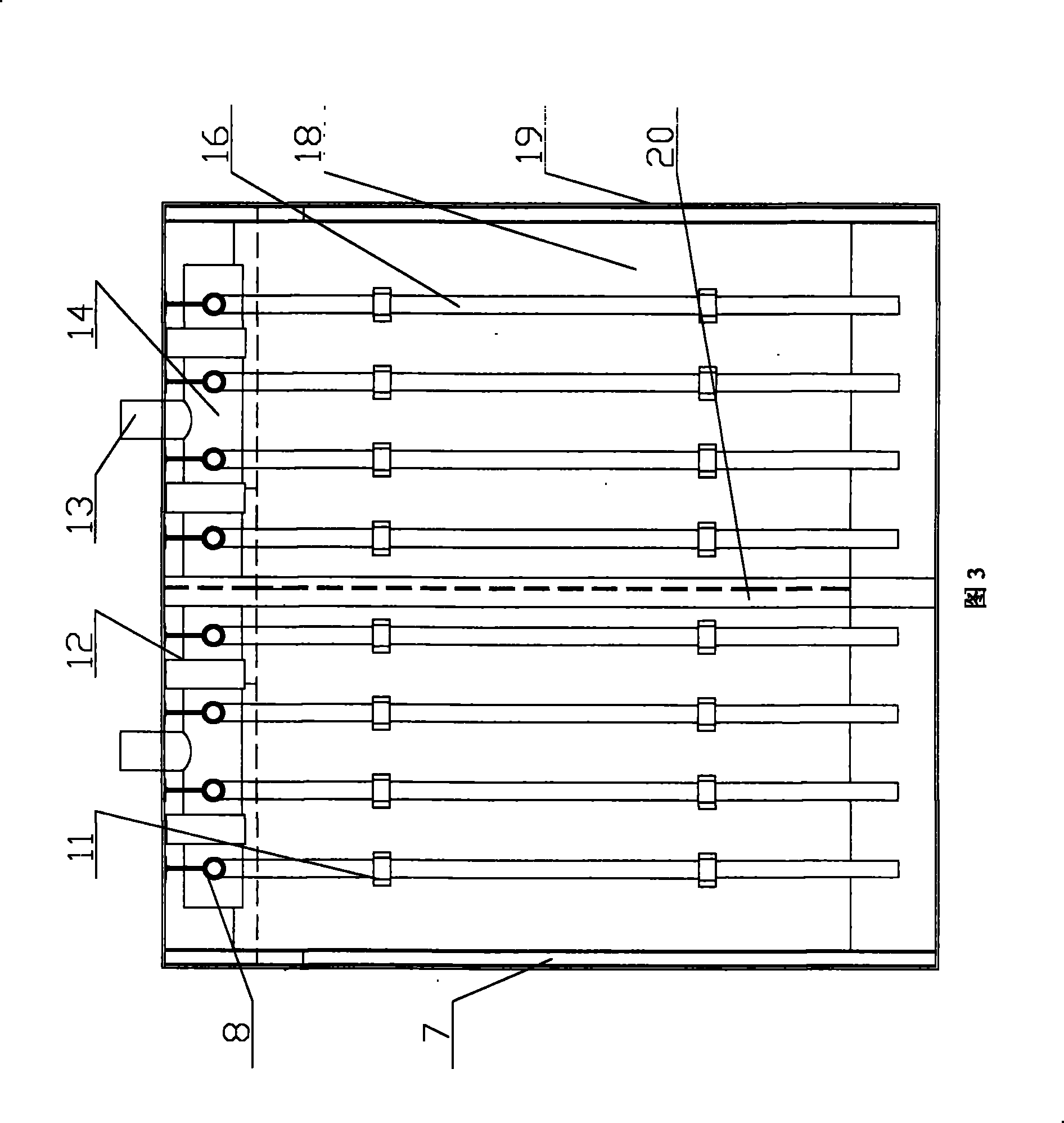

[0031] see figure 1 , figure 2 with image 3 , an efficient and easy-to-clean sewage heat exchanger includes a sewage tank 19, the top of the sewage tank 19 is provided with a flat upper top plate 10, and the inner surface of the upper top plate 10 is evenly equipped with upper baffles 18;

[0032] Four serpentine heat exchange tubes 16 are evenly distributed in the sewage tank 19, and each bend on the upper part of the serpentine heat exchange tubes 16 is connected to the inner side of the upper top plate 10 through fastening hangers 8, and the adjacent serpentine heat exchange tubes The distance between the tubes 16 in the horizontal direction should be large enough to ensure that they can be cleaned manually with a brush, and the distance should be at least greater than 50mm; one end of the serpentine heat exchange tube 16 is connected to the liquid distribution pipe 5, and the other end is connected to the liquid collection pipe 14 ;

[0033] The dispensing pipe 5 is ...

Embodiment 2

[0046] Consider the maintenance and cleaning of the heat exchanger. The upper top plate can be divided into 10 blocks, and one heat exchange tube can be divided into one piece, or two, three, four, etc., and different designs can be carried out according to different situations. figure 2 In the middle, 4 heat exchange tubes are used as a whole, and the whole heat exchanger has a total of 8 heat exchange tubes. Therefore, the upper top plate 10 is divided into two pieces. When cleaning, it can be taken out of the box one by one, rinsed with water or with a brush. Clean up.

[0047] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com