Byproduct collecting apparatus of semiconductor apparatus

A technology for reacting by-products and shells, which is applied in the field of by-product collection devices, can solve the problems of TAT extension, reduced working rate, narrow collection area (narrow space), etc., and achieves the effects of reducing productivity, prolonging work cycle and improving collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

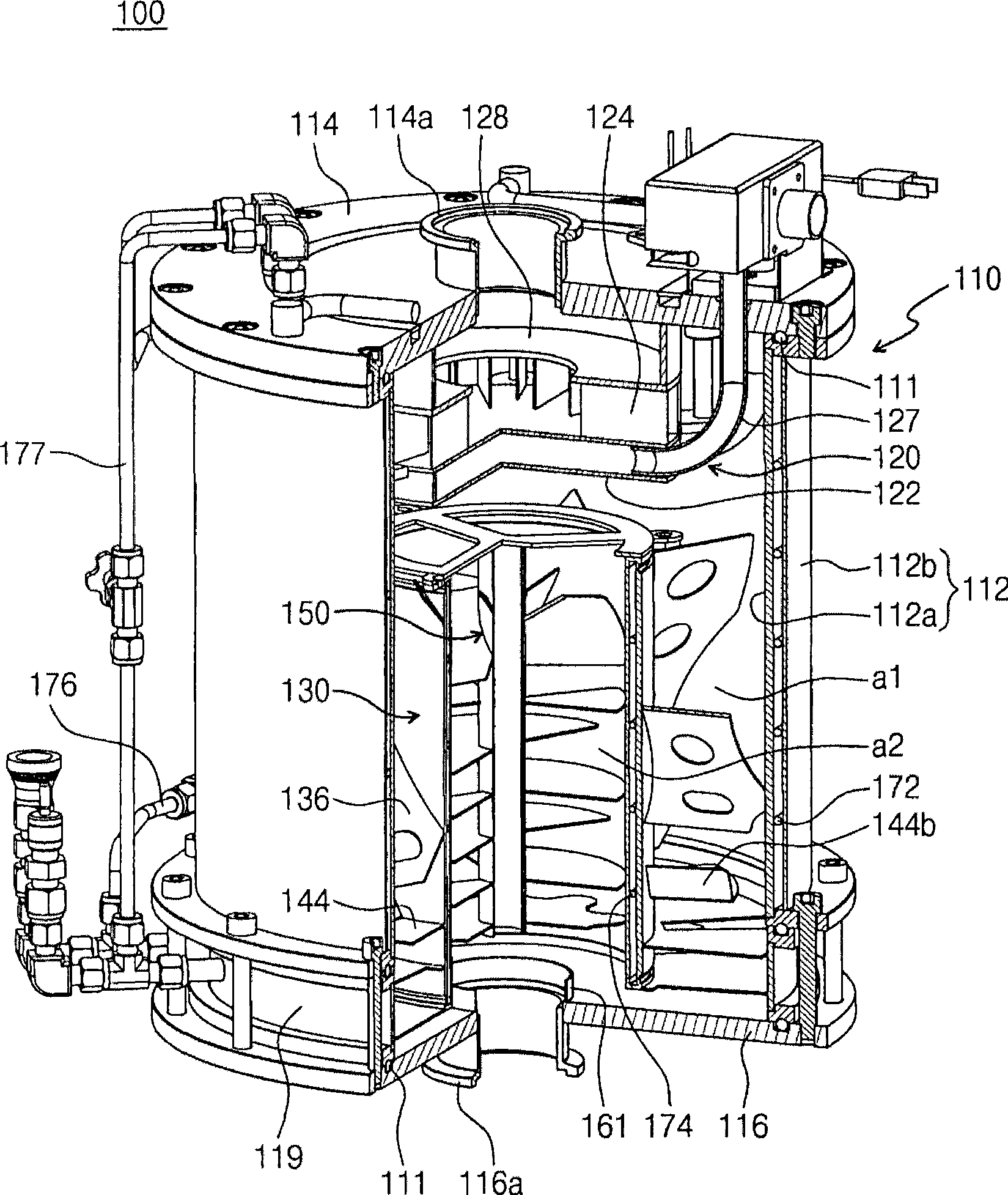

[0053] The structure of the collecting device of the invention allows the exhaust gases to pass through a simple and wide channel at the front and through a complex and narrow channel at the rear, so that the powder can not only accumulate evenly on the front, but also build up on the rear. In addition, the structure of the collecting device of the present invention can double cool the temperature of the exhaust gas on the outside and inside of the casing, thereby reducing the temperature of the exhaust gas more quickly.

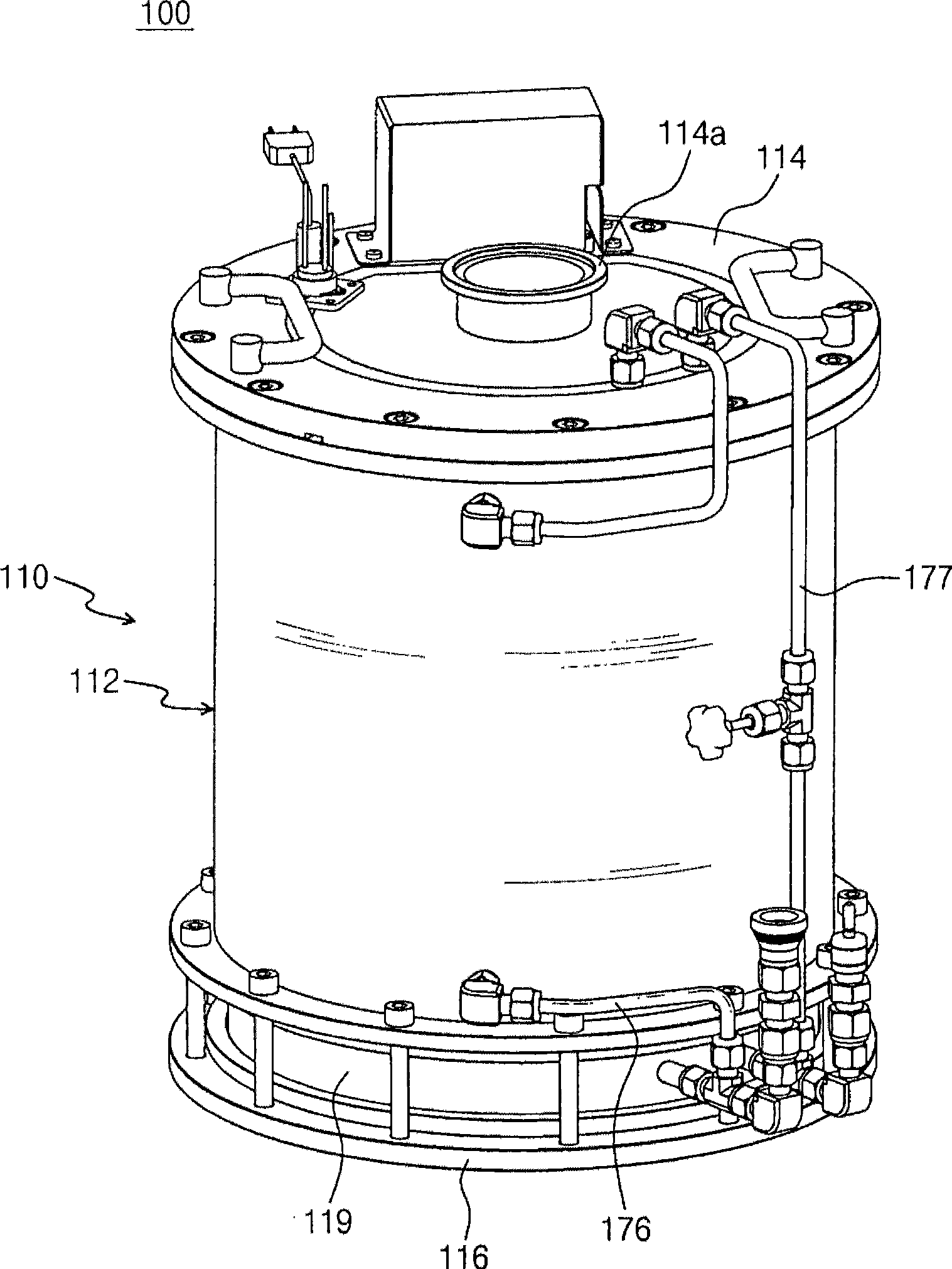

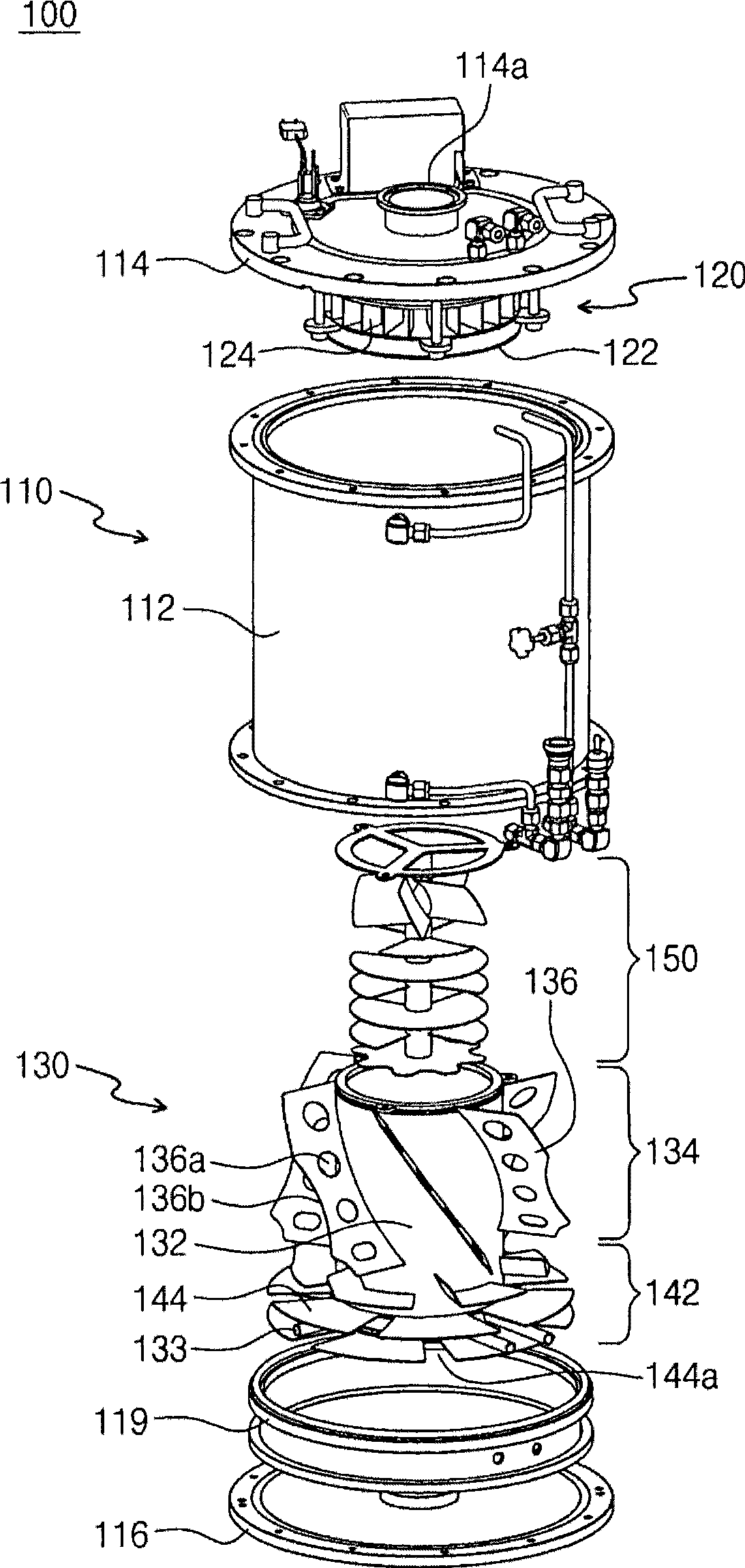

[0054] figure 1 is a view illustrating the appearance of a by-product collecting device of an embodiment of the present invention, figure 2 is a partial cross-sectional view of the by-product collection device, image 3 is an exploded perspective view of the by-product collection device, Figure 4 is a side view illustrating the by-product collection device, and Figure 5 is along Figure 4 A cross-sectional view of line A-A in .

[0055] The by-prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com