Device for calibrating relationship between current of electric machine of numerically controlled machine and cutting load

A technology of motor current and relationship, which is applied in the direction of metal processing machinery parts, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of poor flexibility and adaptability, large consumption of manpower and material resources, and achieve compact device structure, fast response, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is a numerical control machine tool motor current and cutting load relationship calibration device based on the magnetorheological principle, which is used for the calibration of the machine tool feed motor current-cutting resistance relationship and the spindle motor current-cutting torque relationship. Explain in detail.

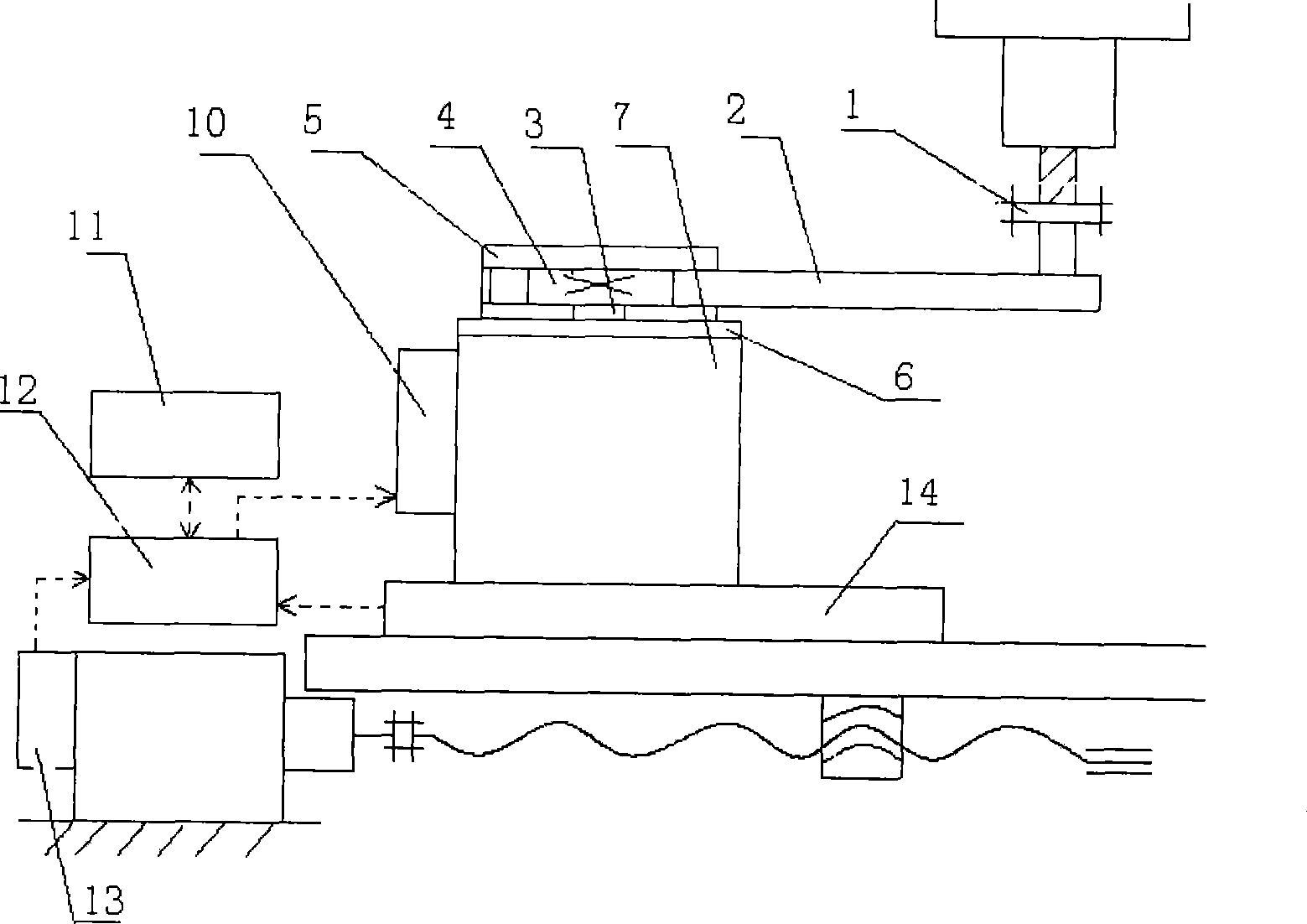

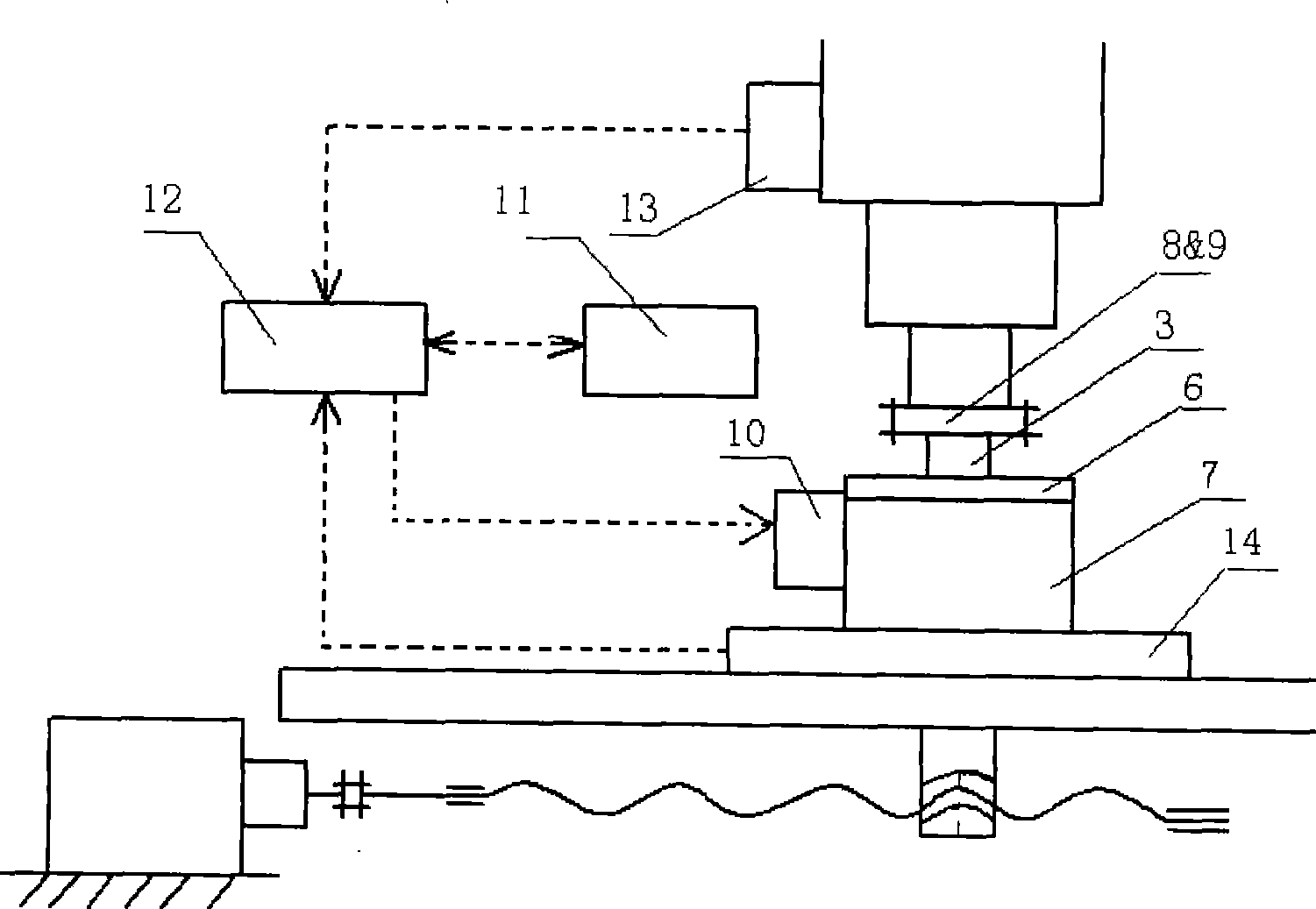

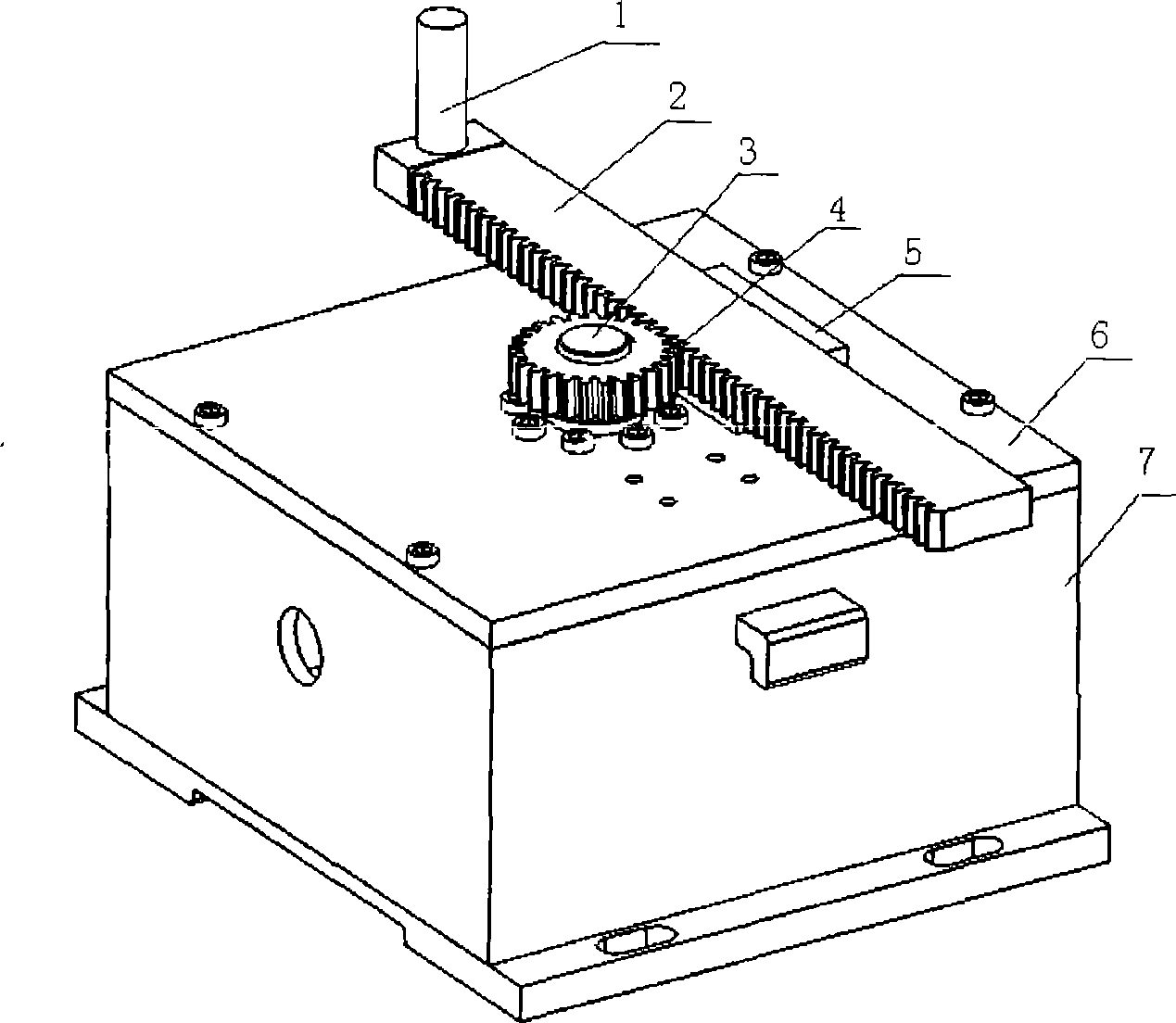

[0026] like figure 1 , 2, 3, 4, the machine tool motor current-cutting load relationship calibration device proposed by the present invention includes a magnetorheological rotary damper 3, a bracket box cover 6, a bracket box 7, a damper controller 10, and a calibration processor. 11. Data acquisition card 12, Hall current sensor 13 and calibration components. The magnetorheological rotary damper 3 is fixed on the support box cover 6 by screws, the support box cover 6 is fixed on the support box body 7 by screws, and the calibration component is connected with the protruding shaft end of the damper 3 . The damper controller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com