Polybutylene terephthalate resion composition and thin film product

A technology of polybutylene terephthalate and resin composition, which is applied in the field of polybutylene terephthalate resin composition and thin-walled molded products, can solve the problems that there is no record of fluidity of resin composition, etc. Achieve excellent fluidity, mechanical strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

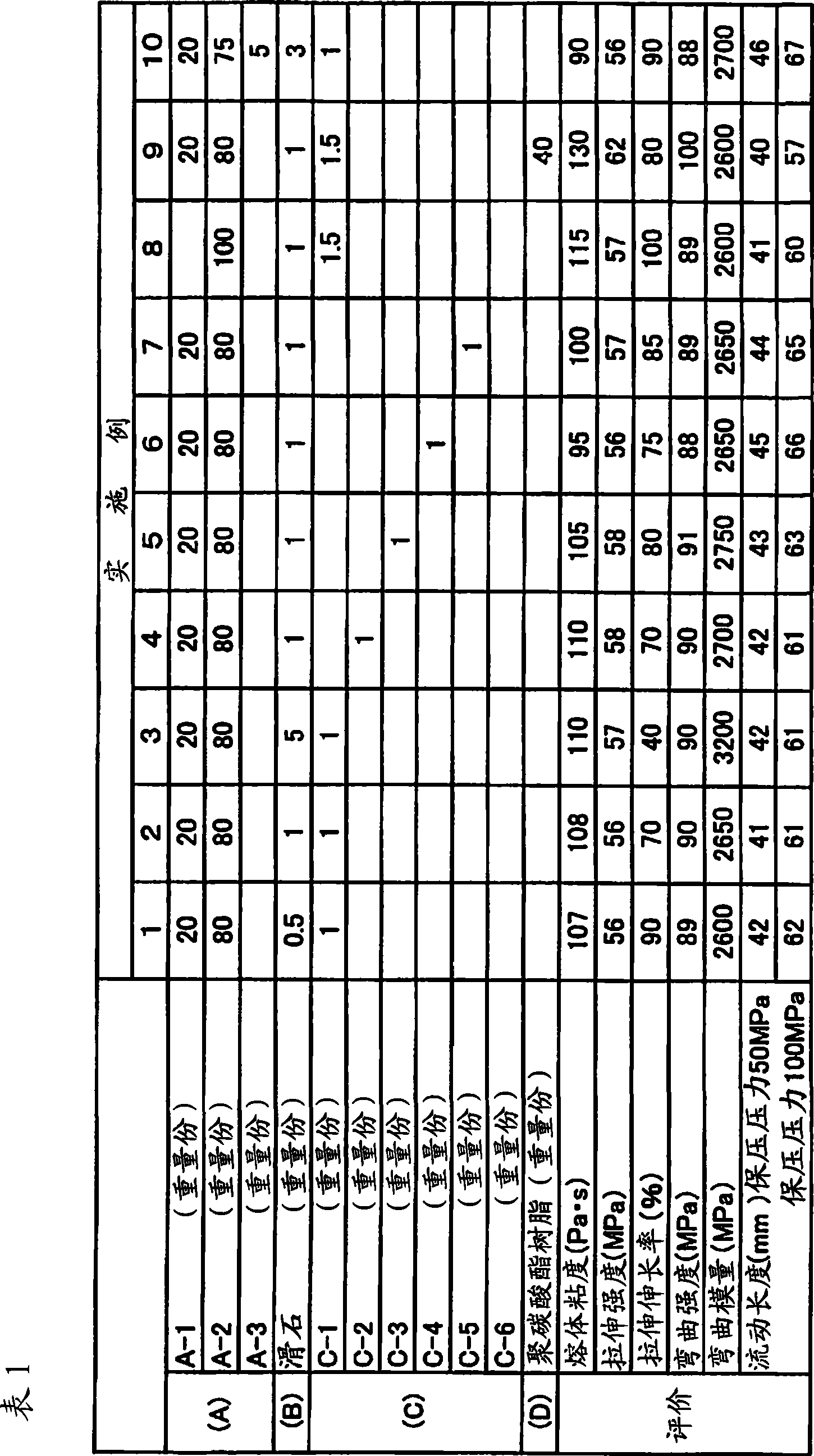

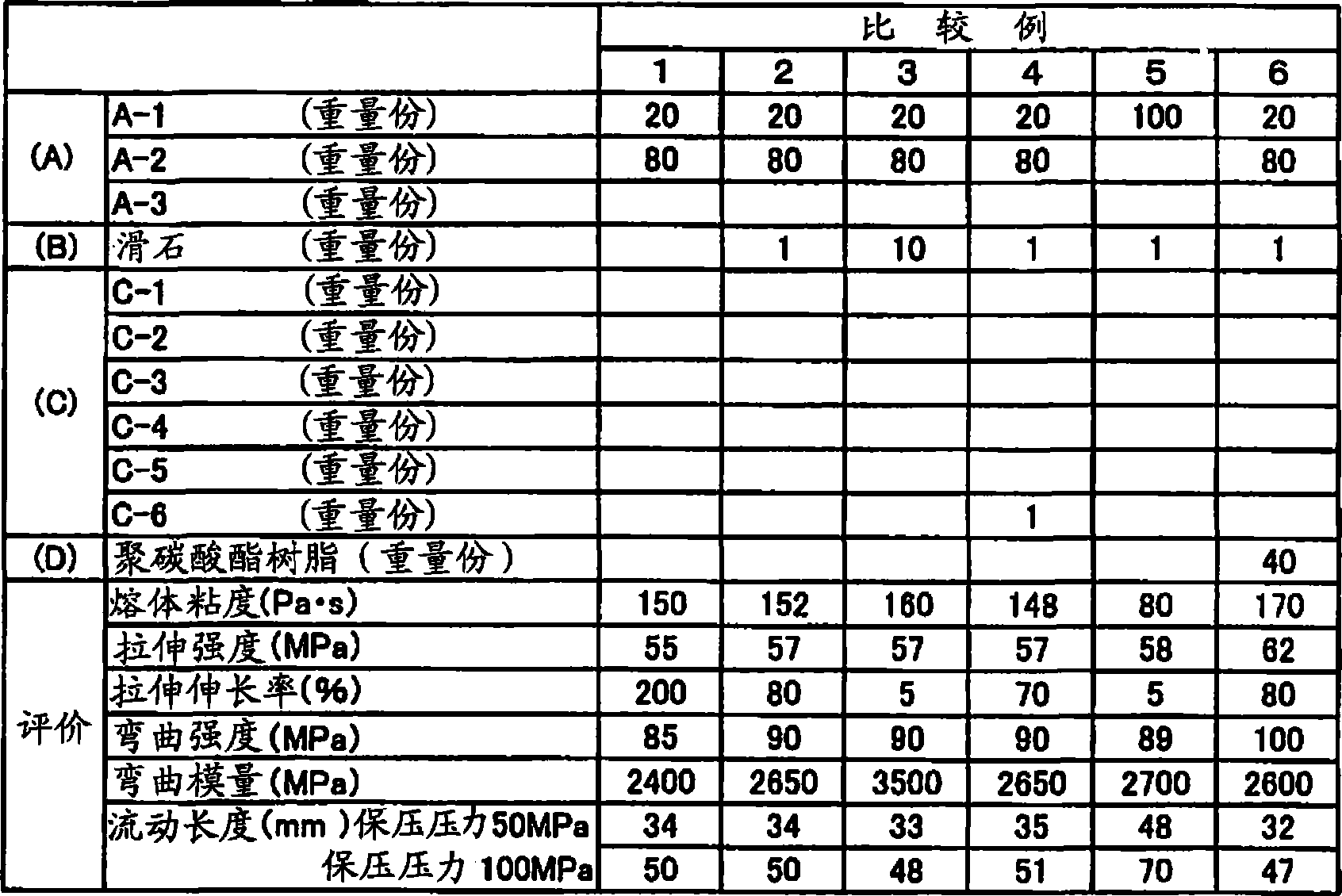

Embodiment 1~10、 comparative example 1~6

[0057] Each resin composition was dry-blended at the mixing ratios shown in Tables 1 and 2, melt-kneaded at 250°C using a twin-screw extruder (manufactured by Nippon Steel Corporation) with a screw of 30 mmΦ, and pelletized. chemically, test pieces were produced, and various evaluations were performed. The results are shown in Tables 1 and 2.

[0058] In addition, the specific content of the components used, and the measuring method of physical-property evaluation are as follows.

[0059] (A) Polybutylene terephthalate resin

[0060] (A-1) Polybutylene terephthalate (intrinsic viscosity IV=0.69 dL / g, manufactured by WinTech Polymer Ltd.).

[0061] (A-2) Polybutylene terephthalate (intrinsic viscosity IV=0.875 dL / g, manufactured by WinTech Polymer Ltd.).

[0062] (A-3) Polyester elastomer ("Neubelane P4110AN" manufactured by Teijin Chemicals Co., Ltd.).

[0063] (B) Talc

[0064] Talc ("MICRON WHITE 5000A" manufactured by Hayashi Kasei Co., Ltd., average particle diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com