Injecting flow guiding silt-proof method

A technology of anti-silting and spraying pipes, which is applied in sea area engineering, water conservancy engineering, climate change adaptation, etc., can solve problems that affect the normal berthing of ships, easy sedimentation, endangering the safety of ships, etc., and achieve the protection of ecological environment and natural landscape , The diversion beam effect is good, and the stability is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

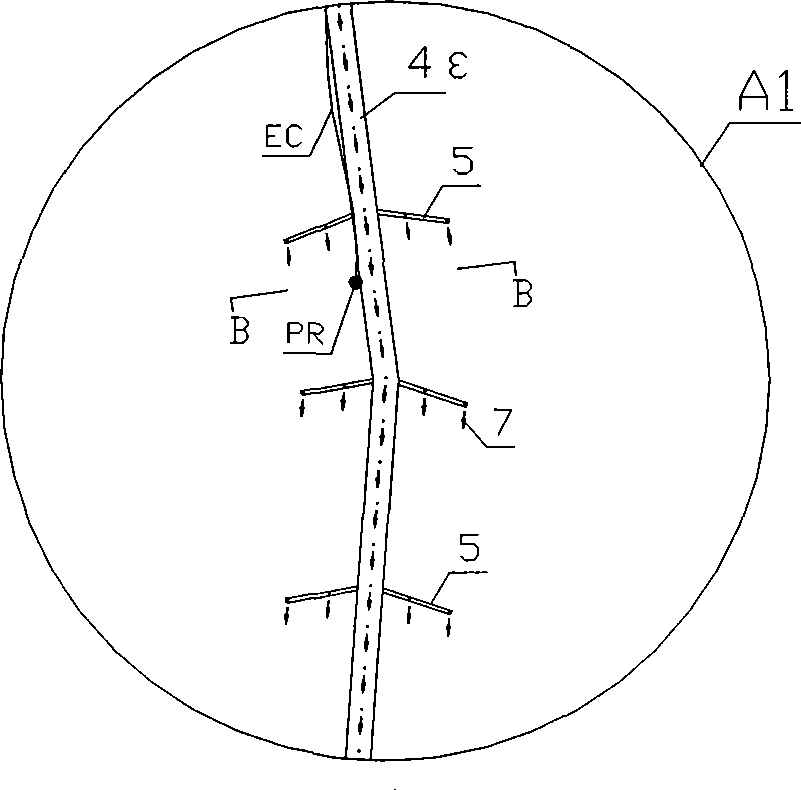

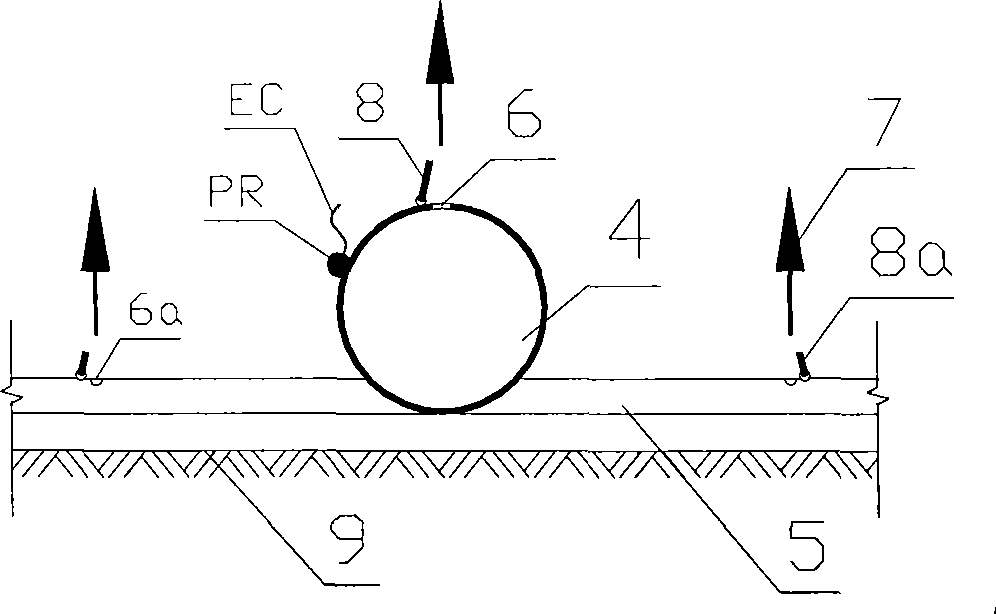

[0036] One or more main pipes are laid on the bottom surface of the main waterway, and spray holes are opened at a certain distance on the upper or lower part or side of the main pipes, and a water column with a certain pressure is injected through the spray holes; pressure measuring devices are installed along the main pipes.

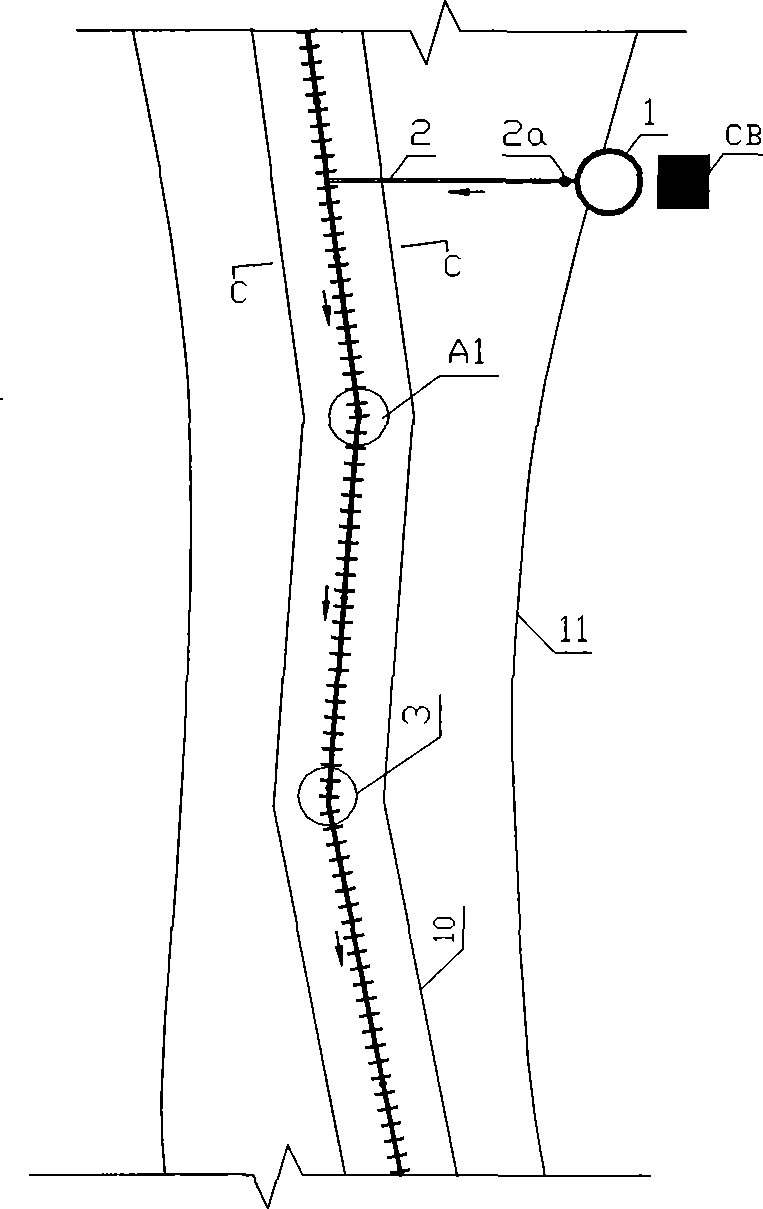

[0037] see Figure 1~4

[0038] 1. Build a water supply facility 1 upstream of the waterway; the water volume of the water supply facility 1 should be able to ensure the continuous supply of water with a certain pressure to the branch pipe network 3 and keep the pressure stable.

[0039] The water supply facilities may be reservoirs, pools, deep wells, water diversion pipes, transmission and distribution networks, pumping stations, public water supply stations and other facilities that can provide a large amount of water.

[0040] 2. Build a monitoring center CB near the water supply facilities to monitor and maintain the normal operation of the jet d...

Embodiment 2

[0048] The pipe network is laid on the bottom surface of the deep water area, and the upper or lower part of the pipe network or the side is provided with injection holes at a certain distance, and a water column with a certain pressure is injected through the injection holes.

[0049] see Figure 5-12

[0050] 1. Build a water supply facility 18 near the harbor basin; the water output of the water supply facility 18 should be able to ensure the continuous supply of water with a certain pressure to the injection pipe network and keep the pressure stable.

[0051] 2. Build a monitoring center CB near the water supply facilities to monitor and maintain the normal operation of the jet diversion system.

[0052] 3. Excavate the harbor basin according to the designed harbor basin location and water depth.

[0053] 4. Lay the injection pipe network on the bottom surface 21 of the harbor basin. The injection network includes a main pipe 14 and a discharge pipe 16 arranged in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com