Vacuum freeze-drying machine

A technology of vacuum freeze-drying and freeze-drying bins, which is applied in local stirring dryers, dryers for static materials, dryers, etc., can solve the problems of inconvenient transportation and maintenance, poor heating effect, and poor water capture effect. Prolonged effect and service life, improved energy efficiency, reduced drying time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

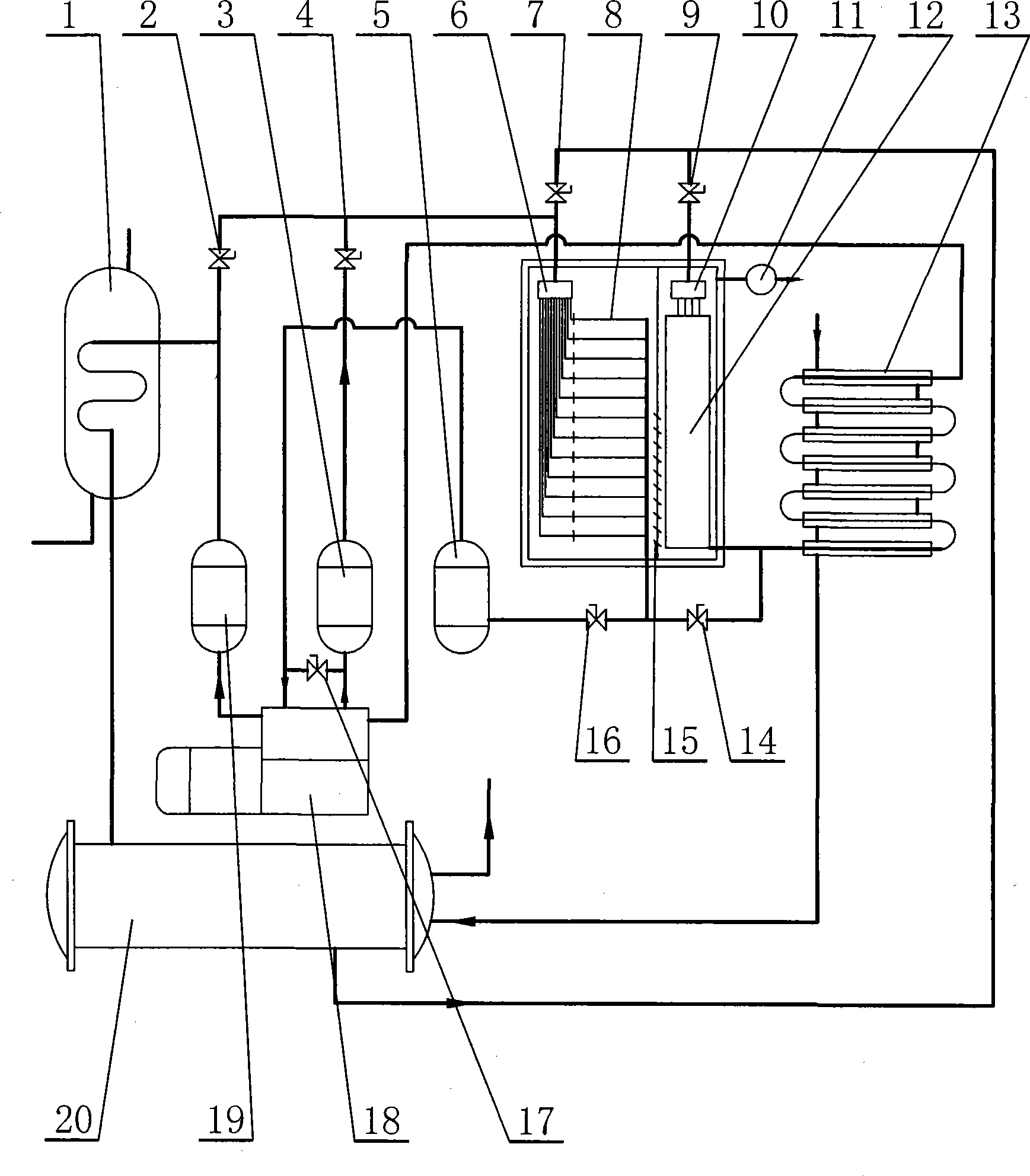

[0010] Such as figure 1 As shown, among them, 1-heating tank, 2-valve VII, 3-oil separator I, 4-valve VI, 5-gas-liquid separator, 6-distributor I, 7-valve I, 8-refrigerated evaporator , 9-valve II, 10-distributor II, 11-vacuum pump, 12-water trap, 13-refrigerant liquid return heater, 14-valve III, 15-baffle, 16-valve IV, 17-valve V , 18-refrigeration compressor unit, 19-oil separator II, 20-condensation receiver.

[0011] The material to be dried is placed in the freezing evaporator through the material tray, and the material is frozen and heated by cold and heat transfer.

[0012] The material freezing process is as follows: At this time, valve I7, valve III14 and valve V17 are opened, valve II9, valve IV16, valve VI4 and valve VII2 are closed, and the refrigeration compressor unit is started. 1. Condensate the accumulator 20 and the valve I7 into the distributor I6, through the distributor I distribute the refrigerant evenly to the material placed on the refrigerated evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com