Sub-wave length metal grating polarizer

A metal grating and polarizer technology, applied in polarizing elements and other directions, can solve the problems of low transmittance and extinction ratio, and achieve the effect of improving transmittance and polarization extinction ratio, and overcoming low transmittance and extinction ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

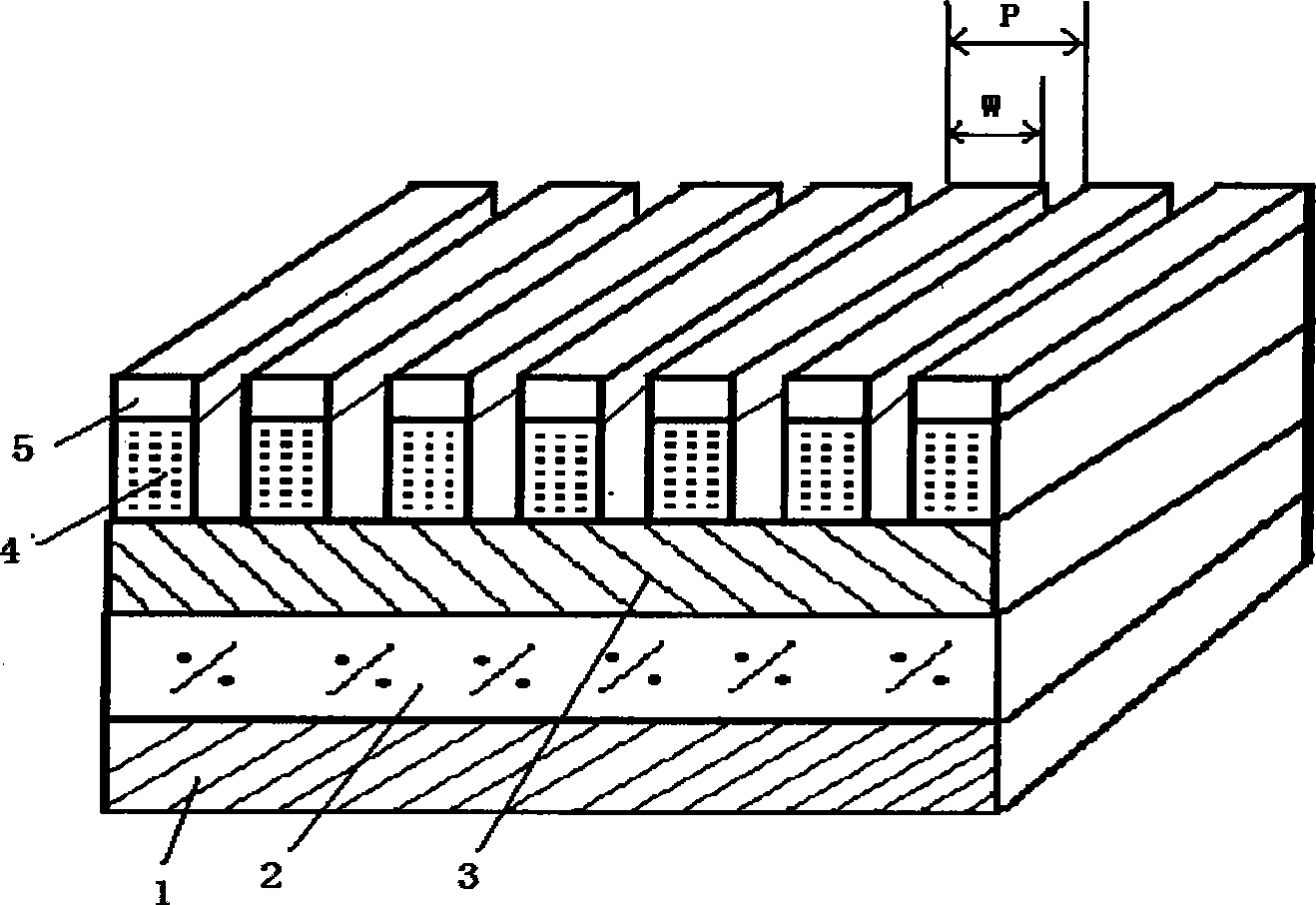

[0023] as CO 2 Laser sub-wavelength metal grating polarizer, multi-layer dielectric anti-reflection film layer 1 and multi-layer dielectric film layer 3 are the same, both made of ZnSe film layer and YF 3 The composition of the film layer, the optical thickness is 2.86μm and 5.94μm respectively; in the multi-layer dielectric anti-reflection coating layer 1, YF 3 The film layer is close to the substrate, and the ZnSe film layer is on the outer layer; in the multilayer dielectric film layer 3, YF 3 The film layer is close to the substrate, and the ZnSe film layer is close to the metal stripe grating 4; the substrate 2 is a polished ZnSe crystal. When the two polished surfaces of the substrate are not coated with multi-layer dielectric anti-reflection coatings, the transmittance at 10.64 μm wavelength is 70%, and both sides are coated with After the multi-layer dielectric anti-reflection coating, the transmittance is over 98%, the material of the metal stripe grating 4 is gold, ...

Embodiment 2

[0025] As a YAG laser (532nm) sub-wavelength metal grating polarizer, the multilayer dielectric antireflection coating layer 1 and the multilayer dielectric coating layer 3 are both made of ZrO 2 film and SiO 2 Composition of film layer, substrate 2 is double-sided polished BK7 glass; when the two polished surfaces of substrate 2 are not coated with multi-layer dielectric anti-reflection coating, the transmittance at 532nm wavelength is 90%, after both sides are coated with multi-layer dielectric anti-reflection coating , the transmittance is greater than 99%, the material of the metal stripe grating 4 is aluminum, the period is 200nm, the duty ratio is 0.5, and the ratio of depth to width is 5:1, so the grating groove depth is 500nm, and the protective layer 5 is Al 2 o 3 , thickness 30nm.

Embodiment 3

[0027] As a broadband sub-wavelength metal grating polarizer, the multilayer dielectric antireflection coating layer 1 and the multilayer dielectric coating layer 3 are broadband multilayer antireflection coatings, both made of ZrO 2 film layer and MgF 2 The substrate 2 is made of BK7 glass material; when the two polished surfaces of the substrate are not coated with multi-layer dielectric anti-reflection coating, the transmittance in the wavelength range of 400nm to 1200nm is 90%. The pass rate is greater than 97%; the material of the metal stripe grating 4 is aluminum, the period is 100nm, the duty ratio is 0.5, and the ratio of depth to width is 2:1, so the groove depth of the grating is 100nm, and the protective layer 5 is MgF 2 , thickness 10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Optical thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com