Clamping mechanism for chucking appliance system

A technology of clamping device and fixture system, applied in the direction of positioning device, clamping, manufacturing tools, etc., can solve the problems of noise pollution, energy consumption, large energy loss, etc., and achieve effective control of output displacement, high energy utilization rate, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

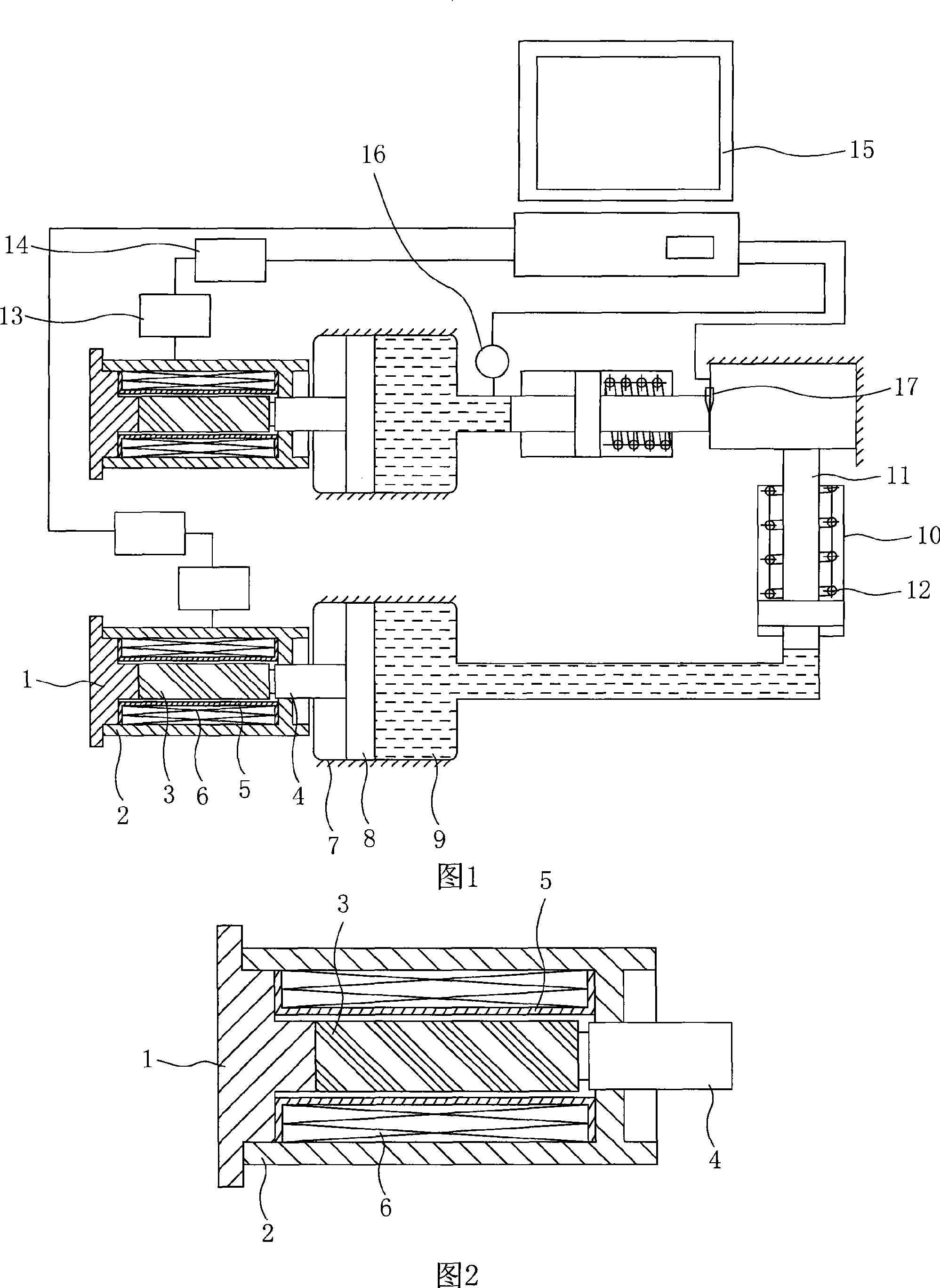

[0035]Embodiment 1: Referring to accompanying drawings 1 to 2, a clamping device for a fixture system includes a micro-displacement driving device, a stroke amplification device and a displacement output device, and the micro-displacement driving device includes a base 1 , the base is provided with a jacket 2 outside, and a giant magnetostrictive rod 3 is arranged inside it. One end of the giant magnetostrictive rod is fixedly connected with the base, and the other end is connected with an output rod 4. The two ends of the giant magnetostrictive rod A skeleton 5 is arranged on the side, and a coil 6 is arranged between the skeleton and the outer jacket; the stroke amplification device includes a piston cylinder 7 with a piston 8 inside, and one end of the piston is connected to the output rod of the micro-displacement drive device. It is fixedly connected, and a hydraulic chamber is formed between the other end and the piston cylinder, and a hydraulic medium 9 is arranged insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com