Heat pump water heater

A heat pump water heater and regenerative heat exchanger technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve problems such as the inability to simultaneously realize compressor heat preservation, low performance of heat pump water heaters, and poor heat dissipation performance of compressors, etc., to achieve Improved heat exchange efficiency, shortened heating time, and improved overload resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

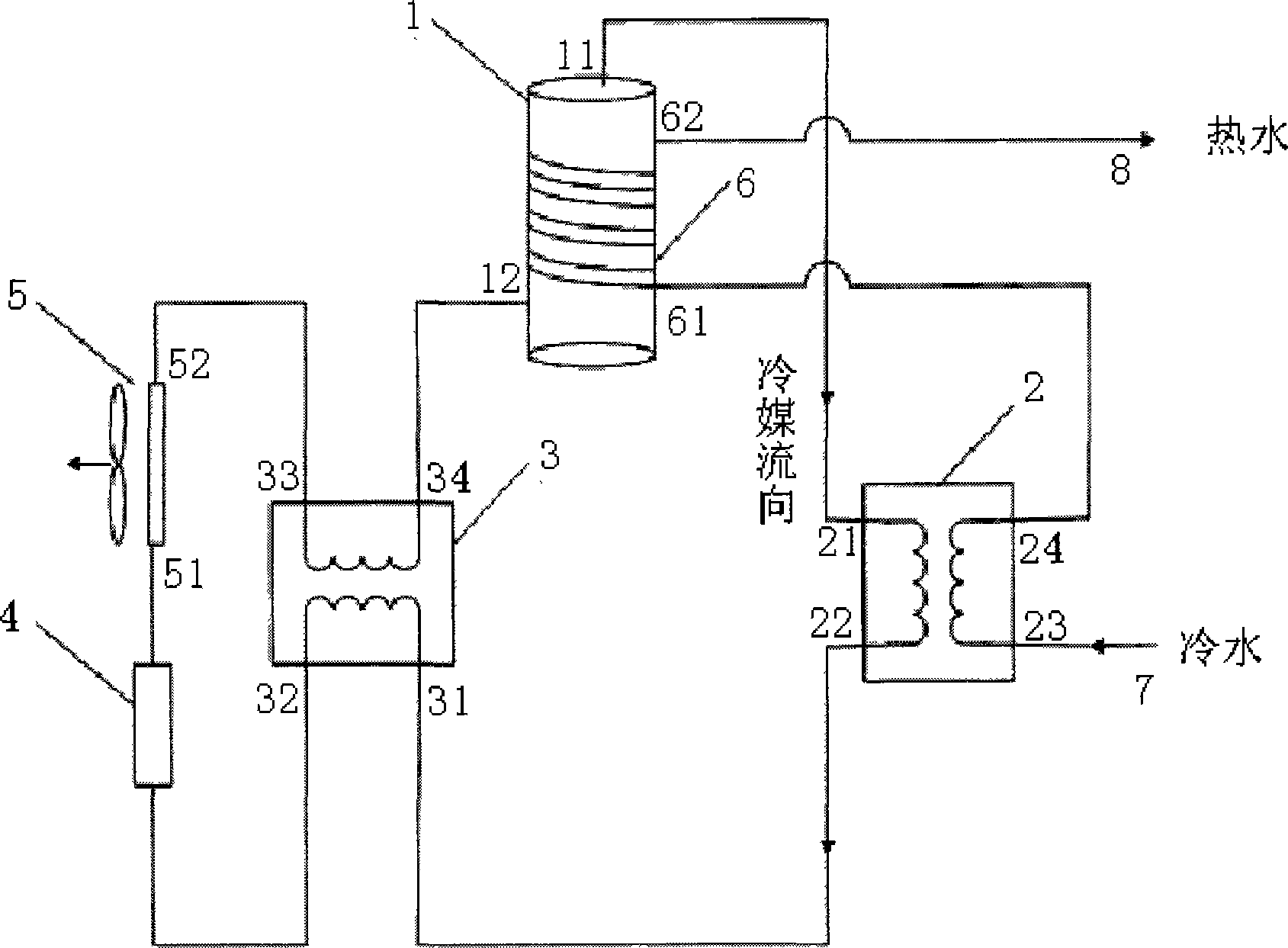

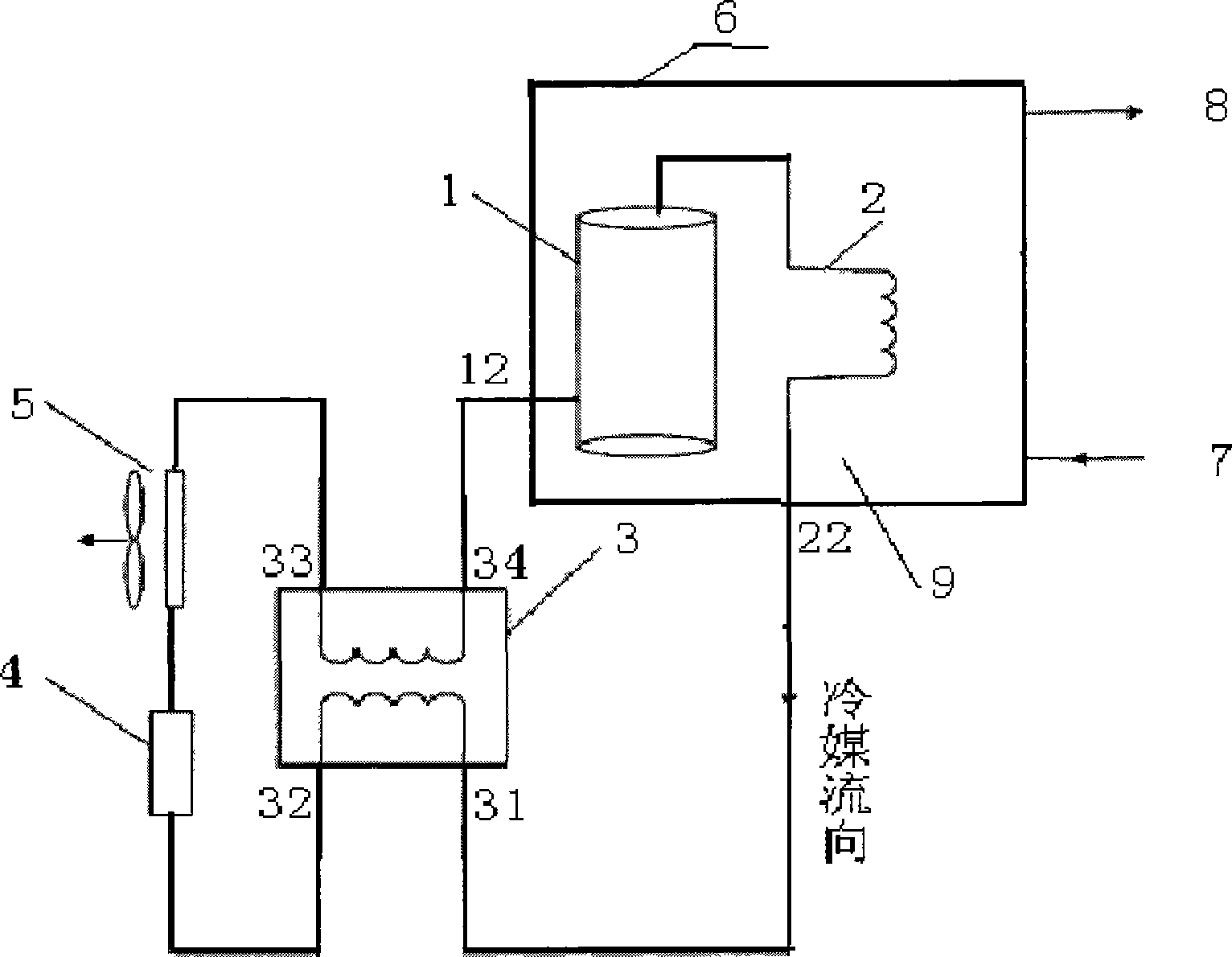

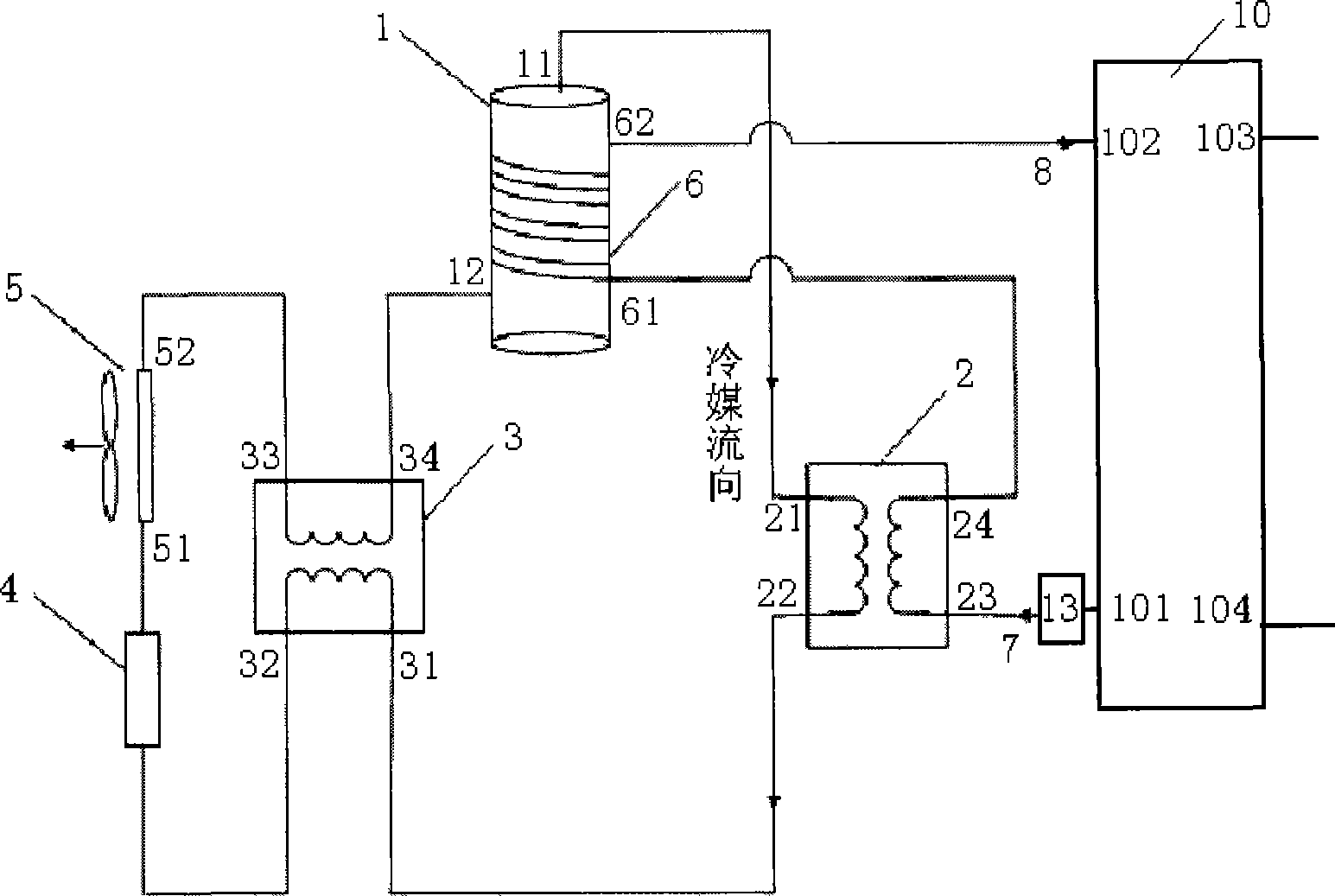

[0047] as attached figure 1 As shown, the heat pump water heater of the present invention includes a compressor 1, a condensation heat exchanger 2, an expansion valve 4, an evaporation heat exchanger 5, a cold water connection 7, a hot water connection 8, a heat recovery heat exchanger 3 and a compressor Shell heat exchanger 6.

[0048] The compressor 1 is provided with a refrigerant outlet 11 and a refrigerant inlet 12, the condensing heat exchanger 2 is provided with a refrigerant inlet 21, a refrigerant outlet 22, and the condensing heat exchanger 2 is also provided with a water inlet 23, The water outflow port 24 is provided with a first refrigerant inflow port 31, a first outflow port 32, a second inflow port 33, and a second outflow port 34 on the heat recovery heat exchanger 3, and a refrigerant inflow port 51 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com