Heating equipment and heating method

A technology of heating equipment and heating section, applied in heat treatment equipment, induction heating, electric/magnetic/electromagnetic heating, etc., can solve the problems of coil cooling water leakage, difficulty in manufacturing coils, complicated system, etc., to achieve overheating and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Next, specific embodiments of the present invention will be described with reference to the drawings.

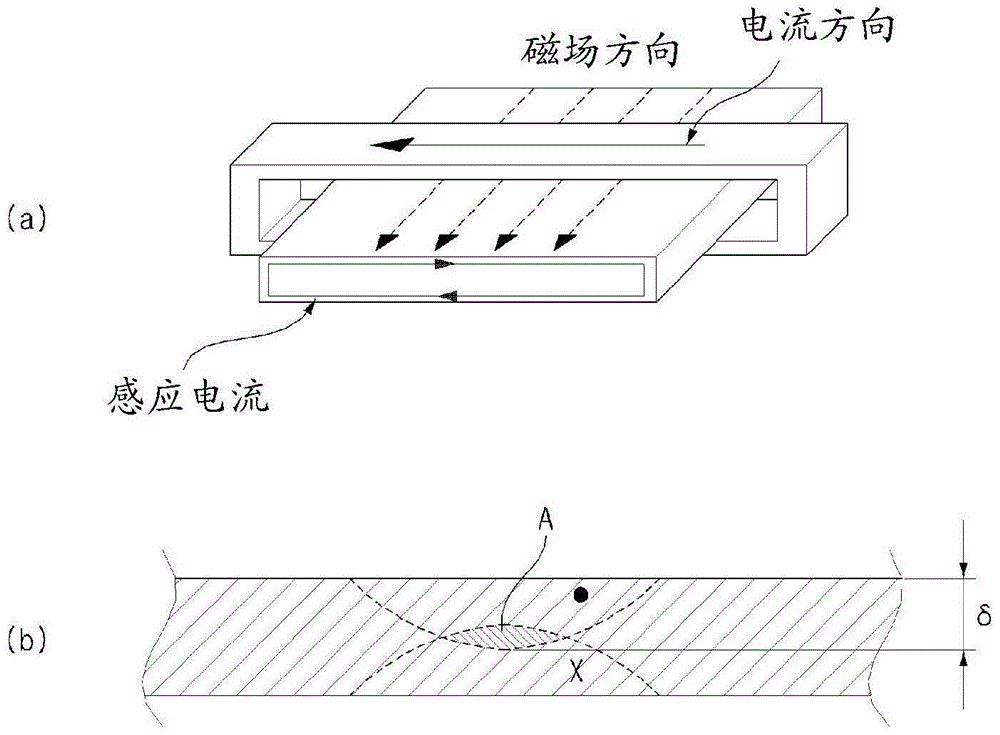

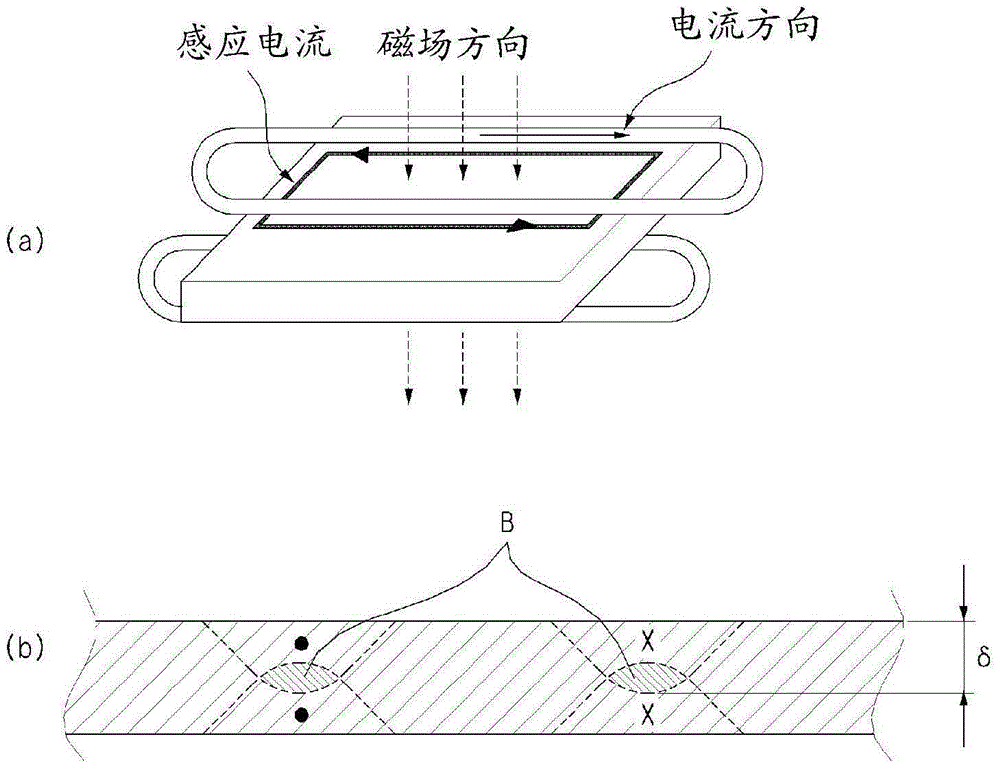

[0059] Figure 5a is a graph showing the eddy current density profile when heated with the TFIC in FIG. 3; Figure 5b is shown in Figure 5a Diagram of the induced eddy current path in the metal plate of . As shown in FIG. 5 , when the TFIC in FIG. 3 is used, it can be seen that eddy currents are concentrated at the edge portion E. As shown in FIG. This is because the magnetic field is distorted and concentrated in the edge portion E, thereby causing an end effect (Endeffect) in which the eddy current density increases.

[0060] The end effect is generated not only at the edge portion E inside the heating coil, but also at the edge portion E’ outside the heating coil, therefore, as Figure 5b As shown, the eddy current loop (Loop) will form an outer current loop in addition to the main current path in the middle part. Eventually, a point where the current splits ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com