Warm washing automatic control system of filtering machine of refinery ketone-benzol combination unit

A technology of automatic control system and combined device, applied in the direction of filtration separation, moving filter element filter, separation method, etc., can solve problems such as increased production cost, poor performance, waste of solvent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

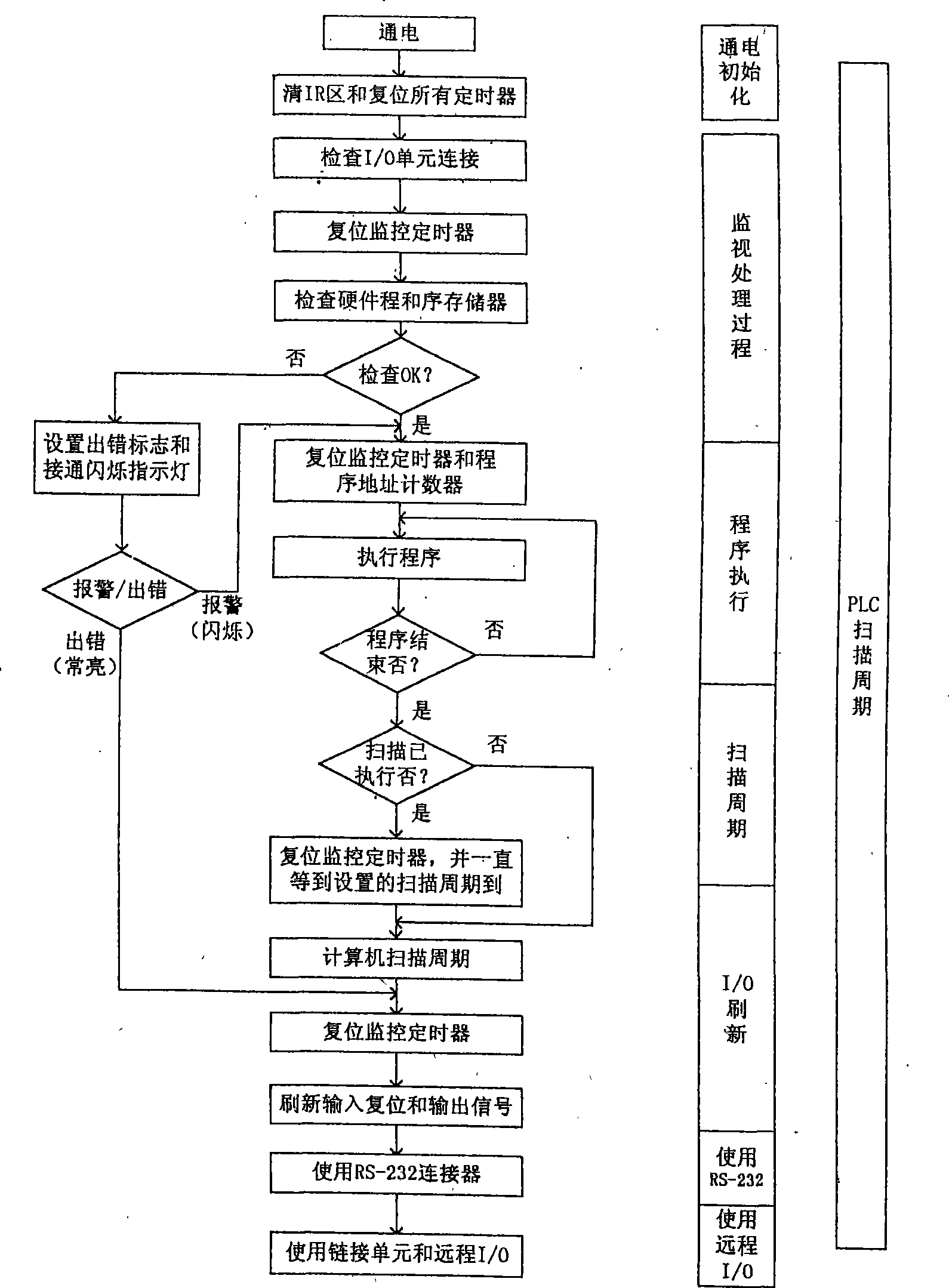

[0018] Embodiment 1, the present invention a kind of oil refinery ketone benzene combined unit filter machine temperature washing automatic control system, it is made up of filter machine computer control system and filter machine system; Described computer control system includes control indoor unit and field unit . The PLC in the control room unit is a programmable controller, and the model selected by the present invention is: SYSMAC CS1, and its technical performance is as follows:

[0019] (1) The CS1 series provides more effective speed and capacity, memory and scalability in terms of CPU performance, which is not only suitable for the present but also can meet the requirements of the future.

[0020] (2) The CS1 series provides multiple ports for serial communication with external devices, providing better compatibility with external devices.

[0021] (3) The CS1 series supports communication through the three-layer network level, and it can even be a different form of...

Embodiment 2

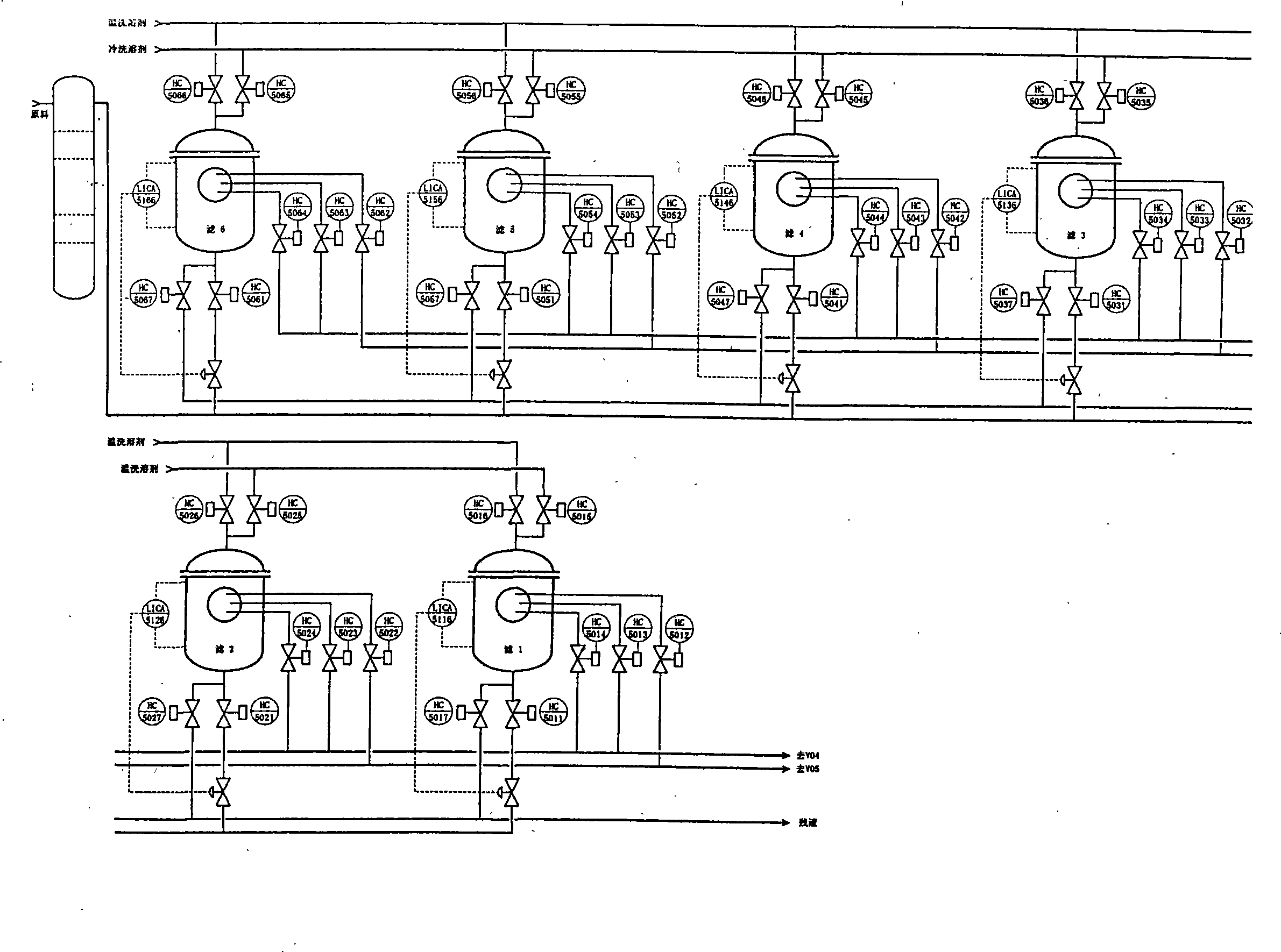

[0023] Embodiment 2, the filter system of the present invention includes a filter liquid level control system and a warm washing process control system; wherein the liquid level control of the filter liquid level control system completes the following three tasks:

[0024] (1) Ensure that the liquid level of the filter is within the specified upper limit and lower limit, so that they have a certain buffer capacity.

[0025] (2) Under normal liquid level conditions, the balance between inlet flow and outlet flow is maintained most of the time.

[0026] (3) Maintain the balance of the front and rear process loads through volume buffering, and adjust the flow rate gradually and smoothly when the flow rate needs to be changed.

[0027] Based on the above three points, it is necessary to control the liquid level of 18 filters. The specific method is:

[0028] Cover the high vacuum section in the distribution head of the filter and add a baffle to keep the liquid level of the filt...

Embodiment 3

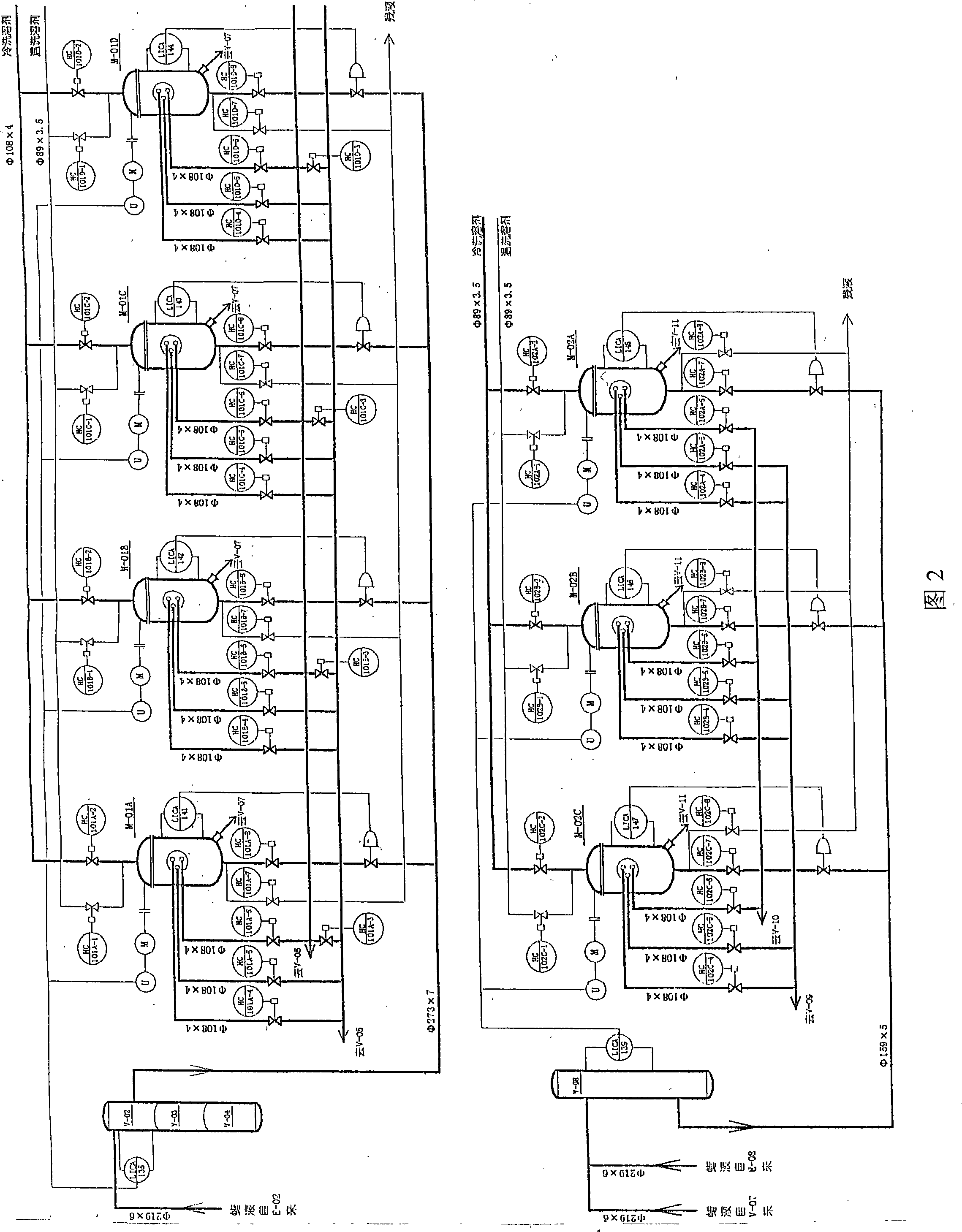

[0029] Embodiment 3, the filter system of the present invention comprises a filter liquid level control system and a warm washing process control system; wherein the various inlet and outlet valves and switch states of the filter of the warm washing process control system are controlled by Computer to do it automatically. According to the process requirements, the logic analysis is carried out on the switch of the valve, and the logic state matching the process requirements is compiled, so as to realize the automatic control of the process. The main control valves include: high vacuum discharge valve, middle vacuum discharge valve, low vacuum discharge valve, residual liquid valve, warm wash solvent feed valve, cold wash solvent feed valve, a total of 112 pneumatic pneumatic gates The valves are all controlled by explosion-proof two-position five-way pilot solenoid valves for ON / OFF control. Through the control of these valves, the operating intensity can be greatly reduced, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com