Coagulation sedimentation method for advanced treatment of printing and dyeing wastewater

A technology for coagulation and sedimentation and printing and dyeing wastewater, which is applied in textile industry wastewater treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of low coagulation and sedimentation efficiency and large amount of coagulant used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

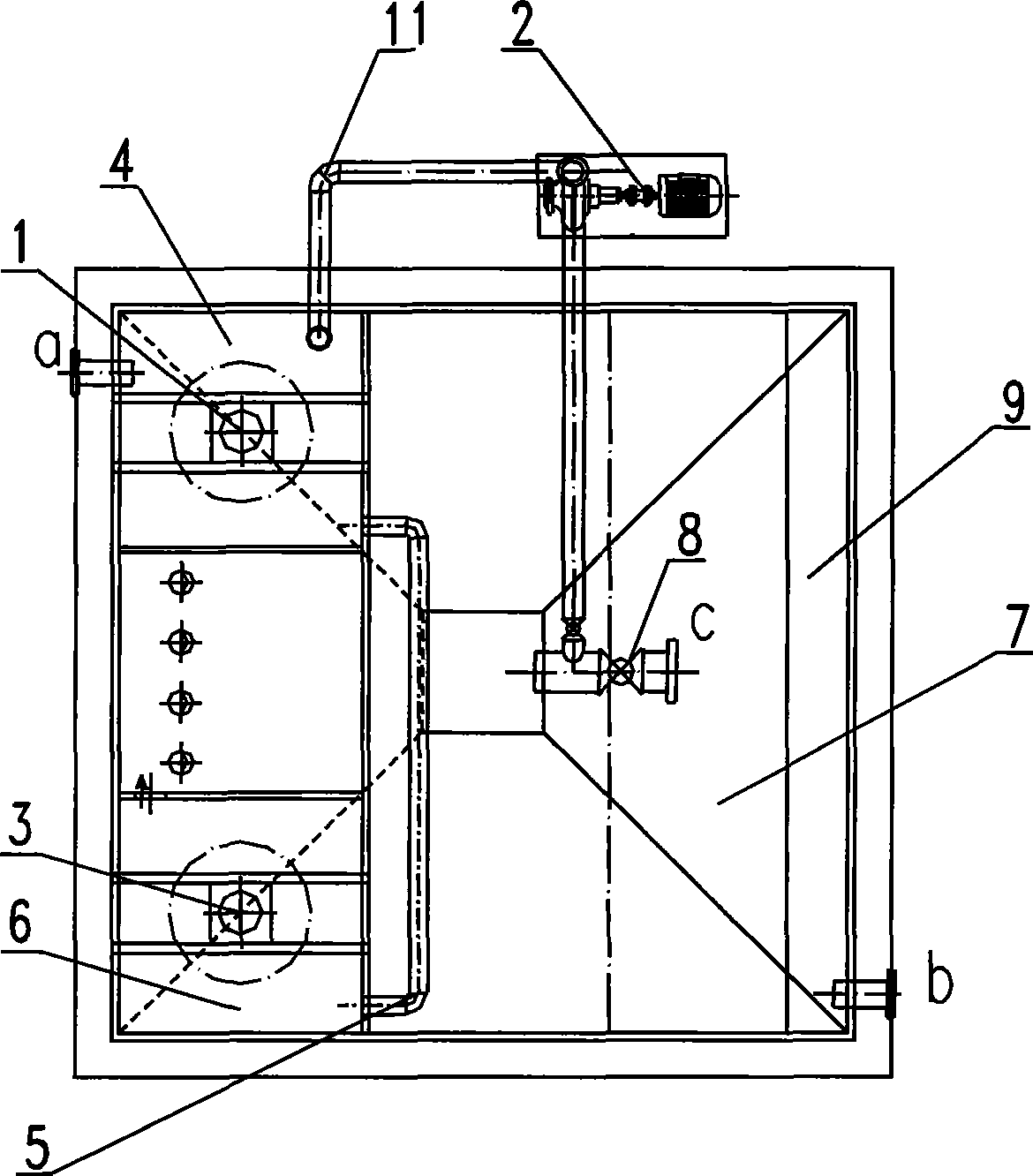

[0017] use as figure 1 The coagulation sedimentation tank with the structure shown is fed into the printing and dyeing wastewater of a certain factory after biochemical treatment (anaerobic hydrolysis + A / O process). The water quality index of printing and dyeing wastewater after biochemical treatment COD: 150.6mg / L, NH 3 -N: 3.45mg / L, TN: 17.2mg / L, TP: 1.2mg / L, chromaticity 80 times. The coagulant is polyaluminum chloride (PAC), and the dosage is 200mg / L. The sludge settling area 12 is equipped with a return pump 2 for sludge return, which is completed through the return pipe 11, and the return ratio is 100%. After the wastewater enters the coagulation sedimentation tank from the water inlet pipe a, it is fully mixed with fresh coagulant and return sludge in the mixing zone 4 under the action of the fast mixer 1, and then enters the coagulation zone 6 through the diversion pipe 5 to coagulate and settle together , the slow speed mixer 3 stirs, and the effluent is collected...

Embodiment 2

[0019] Other operating conditions are the same as in Example 1, but no reflux is used. After treatment, the effluent water quality COD: 69.4mg / L, NH 3 -N: 1.54mg / L, TN: 15.6mg / L, TP: 0.3mg / L, chromaticity 30 times. The removal rate of each index COD: 53.9%, NH 3 -N: 55.4%, TN: 9.3%, TP: 75%, Chroma 62.5%.

Embodiment 3

[0021] Other operating conditions are the same as in Example 1, no reflux is used, the amount of PAC coagulant used is 230mg / L, and the effluent quality COD after treatment: 58.4mg / L, NH 3 -N: 1.12mg / L, TN: 14.6mg / L, TP: 0.3mg / L, chromaticity 20 times. The removal rate of each index COD: 61.2%, NH 3 -N: 67.5%, TN: 15.1%, TP: 75%, Chroma 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com