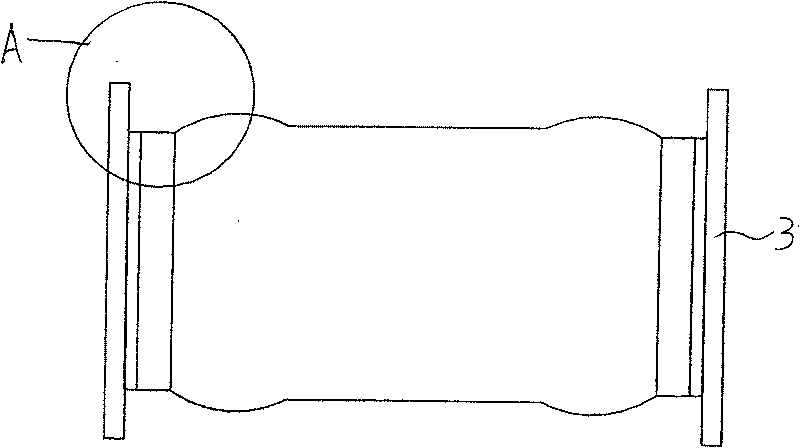

Mud suction and drainage hose

A technology of mud glue and inner rubber layer, which is applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of easy corrosion, large corrosion of suction mud pipe, increase in cost, etc., to improve corrosion resistance, Improve the effect of medium corrosion resistance and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

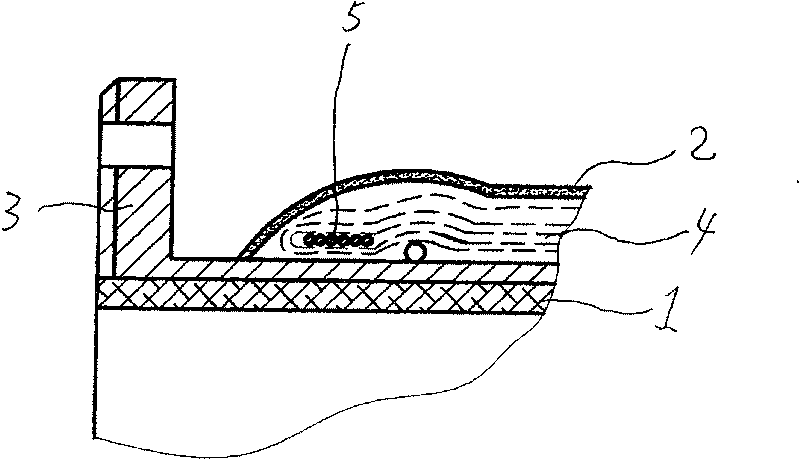

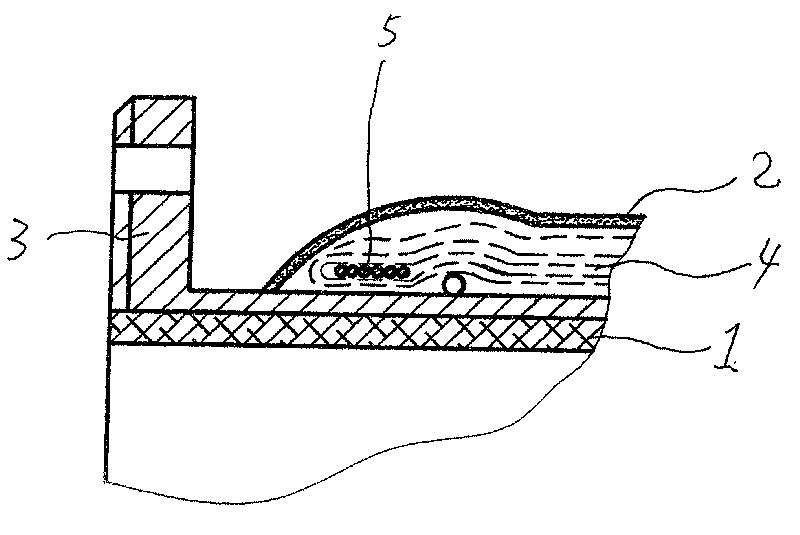

Method used

Image

Examples

Embodiment 1

[0052] The first step is to prepare raw materials and make inner rubber compound and outer rubber compound

[0053] Take 75 kg of natural rubber, 25 kg of styrene-butadiene rubber, 4 kg of zinc oxide, 3 kg of stearic acid, 80 kg of carbon black, 2 kg of sulfur, 1.0 kg of accelerator CZ, 20 kg of pine tar, 30 kg of light calcium, and 1.0 kg of paraffin kg, 2.0 kg of anti-aging agent A, 10 kg of coumarone, crushed and mixed, and mixed with various raw materials through an internal mixer to make inner rubber compound rubber;

[0054] Take 60 kg of natural rubber, 40 kg of styrene-butadiene rubber, 5 kg of zinc oxide, 4 kg of stearic acid, 60 kg of carbon black, 1 kg of sulfur, 2.0 kg of accelerator DM, 18 kg of pine tar, 80 kg of light calcium, and 1.5 kg of paraffin kg, 2.0 kg of anti-aging agent A, crushed and mixed, and mixed with various raw materials through an internal mixer to make the outer rubber compound;

[0055] The second step of heating:

[0056] Put the inner rub...

Embodiment 2

[0070] The first step is to prepare raw materials and make inner rubber compound and outer rubber compound

[0071] Take 75 kg of natural rubber, 25 kg of styrene-butadiene rubber, 5 kg of zinc oxide, 3 kg of stearic acid, 65 kg of carbon black, 2 kg of sulfur, 1.0 kg of accelerator CZ, 12 kg of pine tar, 15 kg of light calcium, and 1 kg of paraffin kg, 1.0 kg of anti-aging agent A, 5 kg of coumarone, crushed and mixed, and mixed with various raw materials through an internal mixer to make inner rubber compound rubber;

[0072] Take 60 kg of natural rubber, 40 kg of styrene-butadiene rubber, 8 kg of zinc oxide, 4 kg of stearic acid, 40 kg of carbon black, 1.5 kg of sulfur, 1.5 kg of accelerator DM, 20 kg of pine tar, 85 kg of light calcium, and 1.5 kg of paraffin kg, 2.0 kg of anti-aging agent A, crushed and mixed, and mixed with various raw materials through an internal mixer to make the outer rubber compound;

[0073] Step 5: Preparation of the reinforcement layer

[0074]...

Embodiment 3

[0079] The first step is to prepare raw materials and make inner rubber compound and outer rubber compound

[0080] Take 75 kg of natural rubber, 25 kg of styrene-butadiene rubber, 6 kg of zinc oxide, 3 kg of stearic acid, 50 kg of carbon black, 2 kg of sulfur, 1.0 kg of accelerator CZ, 10 kg of pine tar, 15 kg of light calcium, and 2 kg of paraffin kg, 1.0 kg of anti-aging agent A, 5 kg of coumarone, crushed and mixed, and mixed with various raw materials through an internal mixer to make inner rubber compound rubber;

[0081] Take 60 kg of natural rubber, 40 kg of styrene-butadiene rubber, 8 kg of zinc oxide, 5 kg of stearic acid, 40 kg of carbon black, 2 kg of sulfur, 1 kg of accelerator DM, 10 kg of pine tar, 60 kg of light calcium, and 1.0 kg of paraffin kg, 1.5 kg of anti-aging agent A, crushed and mixed, and mixed with various raw materials through an internal mixer to make the outer rubber compound;

[0082] Step 5: Preparation of the reinforcement layer

[0083] Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com