Air cooling system of motor

An air-cooling system and body technology, applied in the field of electric motors, can solve the problems of life reduction, weight increase, and equipment size being too large, and achieve good heat dissipation effect, good heat dissipation effect, and the effect of saving consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

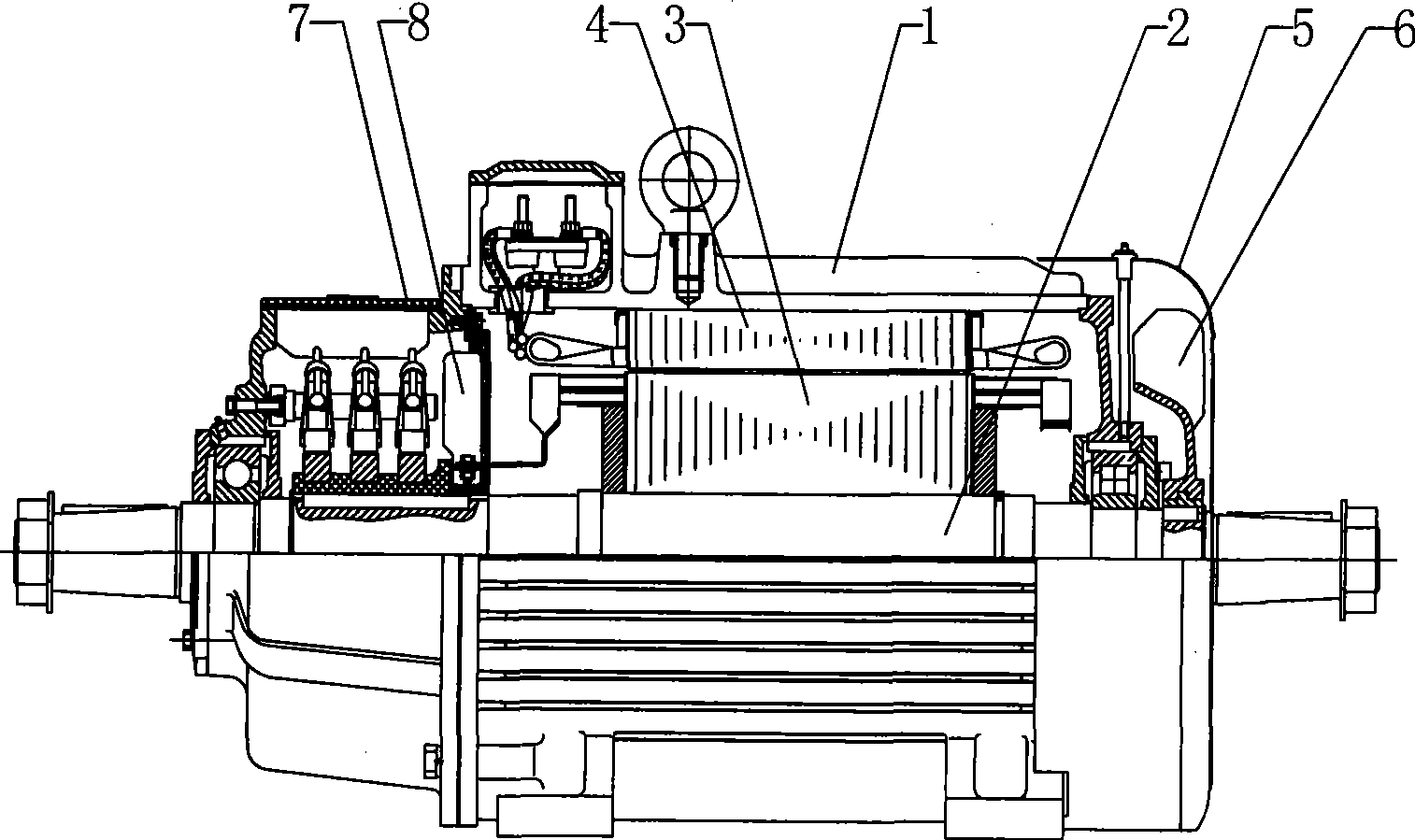

[0013] like figure 1 As shown, an air cooling system for a motor includes a body 1 and a shaft 2, a stator 3 and a rotor 4 are installed inside the body 1, the rotor 4 is fixed on the shaft 2, and a windshield 5 is provided on one side of the body 1 , the other side is provided with an end cover 7, a fan 6 is built inside the wind cover 5, and a fan 8 is also provided inside the end cover 7, and the two fans 6, 8 are installed on the crankshaft 2 of the motor.

[0014] The air-cooling system of the present invention can not only play a good heat dissipation effect on the stator 3 and the rotor 4, but also can play a good heat dissipation effect on the equipment inside the end cover 7, so that the structure of the equipment inside the end cover 7 is more efficient. Compact, which reduces the size of the equipment and reduces the space occupied by the equipment, so consumables are saved, and the weight of the equipment is also reduced, making it relatively more convenient to car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com