Electronic ballast of HID lamps

An electronic ballast and circuit technology, applied in the direction of electric light sources, electrical components, lighting devices, etc., can solve the problems of poor first-order system stability, slow load response speed, power factor reduction, etc., to achieve fast load response speed, system Good stability and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

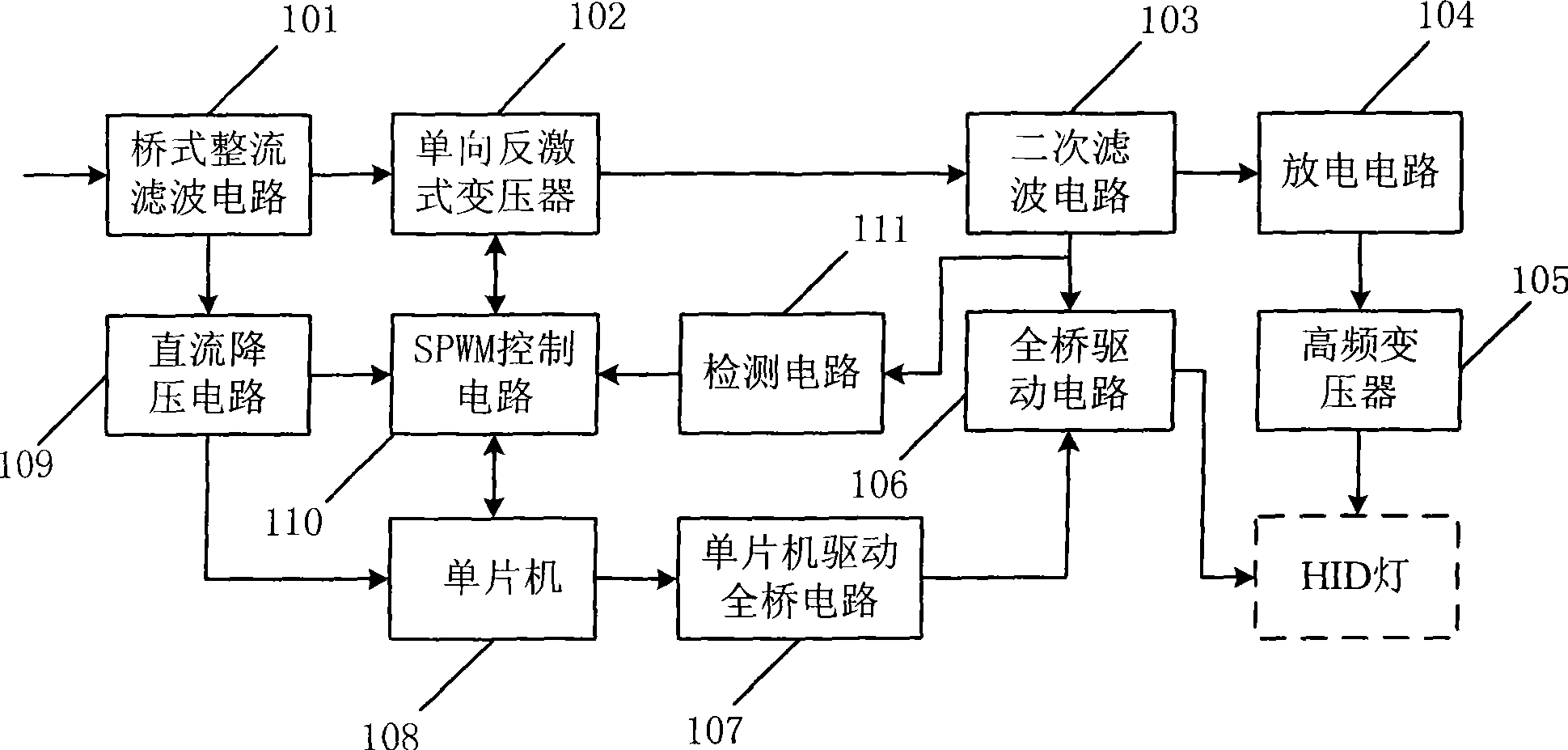

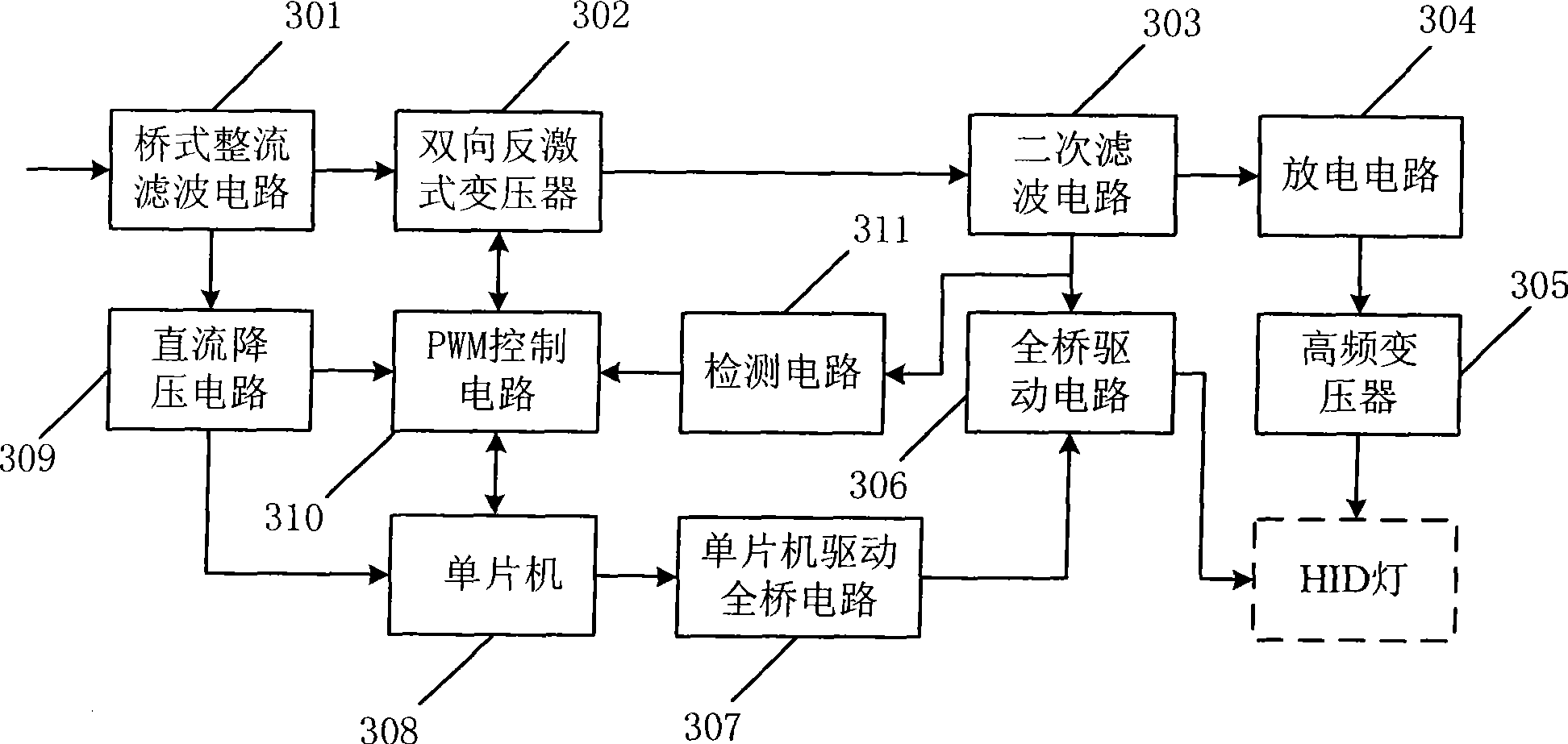

[0028] refer to image 3 , the HID lamp electronic ballast of the present invention comprises: comprise bridge type rectification filter circuit 301, secondary filter circuit 303, discharge circuit 304, high-frequency transformer 305, full-bridge driving circuit 306, single-chip microcomputer driving full-bridge circuit 307, single-chip microcomputer 308 , DC step-down circuit 309 and detection circuit 311, bridge rectifier filter circuit 301 is connected with DC step-down circuit 309, secondary filter circuit 303 is connected with discharge circuit 304, full bridge drive circuit 306, detection circuit 311 respectively, discharge circuit 304 Connect with the high-frequency transformer 305, the high-frequency transformer 305 is connected with the HID lamp, the full-bridge drive circuit 306 is connected with the single-chip microcomputer 307, the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com