Improved ceramic foam filter for better filtration of molten iron

A filter material, ceramic filtration technology, applied in ceramic products, filtration separation, application, etc., can solve problems such as no one found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The materials listed in Table 1 were used to prepare ceramic precursor compositions. In Table 1, the refractory aluminosilicate used was Mulcoa 60 available from C-E Minerals It has been ground to about 325 mesh. The colloidal silica used was obtained from the company Nyacol. The modified bentonite used was obtained from Wyo-Ben Company. The fumed silica used was obtained from C-E Minerals. The composition was fired at 1200°C for 30 minutes. Fumed silica can be used instead of fumed silica in order to improve the ability of porous ceramics in the fired state to be cut. The modulus of rupture measured at room temperature is reported in Table 2. The modulus of rupture measured at elevated temperature is reported in Table 3.

[0045] Table 1

[0046] Element weight% High temperature resistant aluminosilicate 54.50 Colloidal silica 21.00 Modified bentonite 0.75 Fumed silica 17.75 water 6.00

[0047] The average room tem...

Embodiment 2

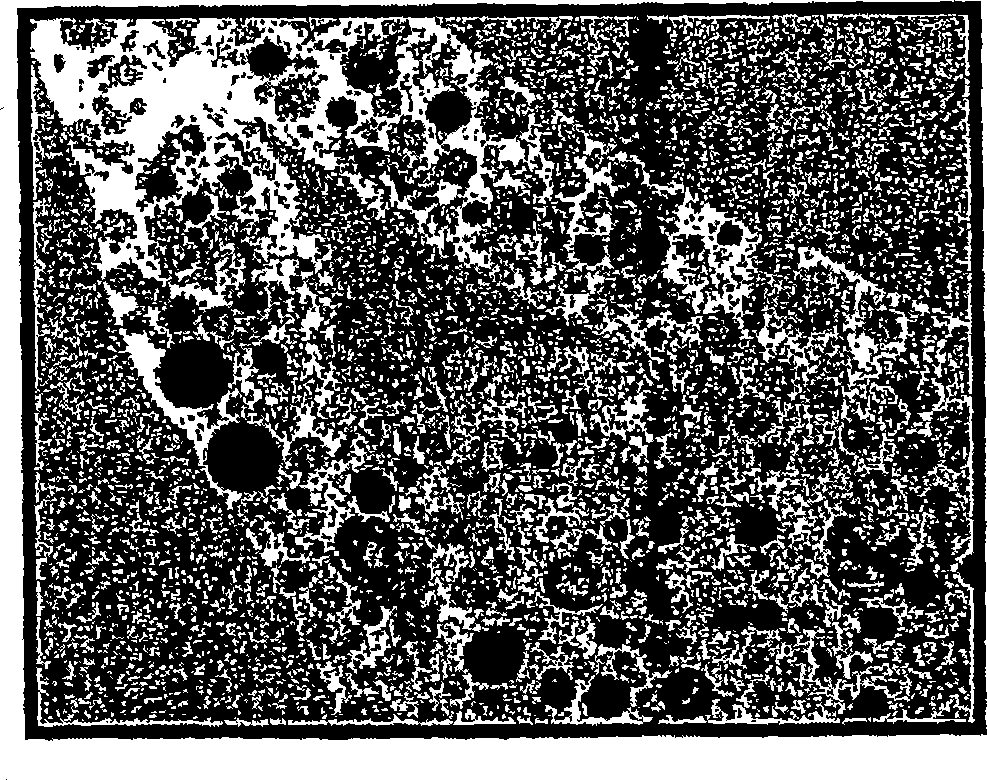

[0054] In order to improve the interception ability and retention capacity for liquid slag, the composition was prepared according to the ingredients listed in Table 1, and additionally added 4% by weight of hollow organic spheres with a diameter of 80 microns. The resulting filter material was observed under a microscope, and its final microstructure is shown in figure 2 . When the liquid slag wets the mullite body, it is sucked into the micropores by capillary action.

Embodiment 3

[0056] Using the compositions provided in Table 4, filter materials were prepared under the same conditions as in Example 1. Using Mulcoa 70 available from C-E Minerals As a high temperature resistant aluminosilicate.

[0057] Table 4

[0058] Element weight% High temperature resistant aluminosilicate 54.5 Colloidal silica 21.0 Modified bentonite 0.8 Fumed silica 17.8 water 5.9

[0059] When the average relative density of the porous body is 14%, the measured average high temperature rupture modulus is 34 psi.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com