Low-temperature prewarming and flattening method of normalizing furnace

A technology of normalizing furnace and preheating and pressing, which is applied in the direction of furnace, furnace type, heat treatment furnace, etc., can solve the problems of increasing the transportation and transfer of the intermediate process of steel plate, failing to meet the requirements of technical conditions, and damaging the company's image and reputation, etc., to simplify production process, reduce the generation of unplanned quantities, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

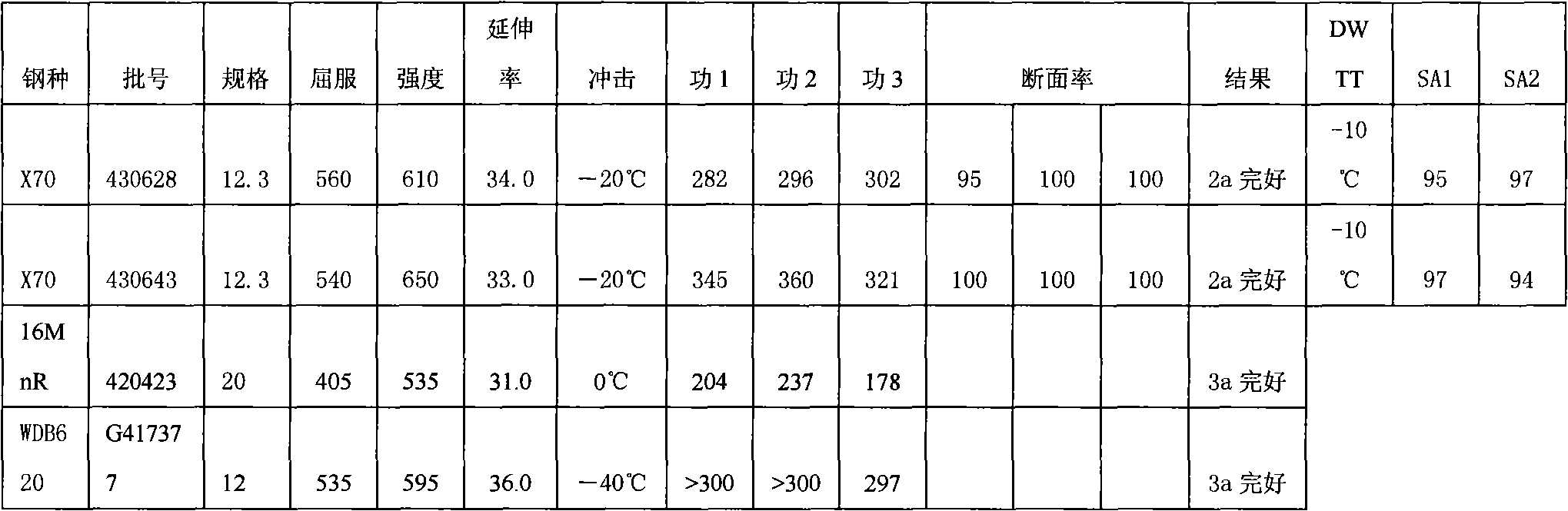

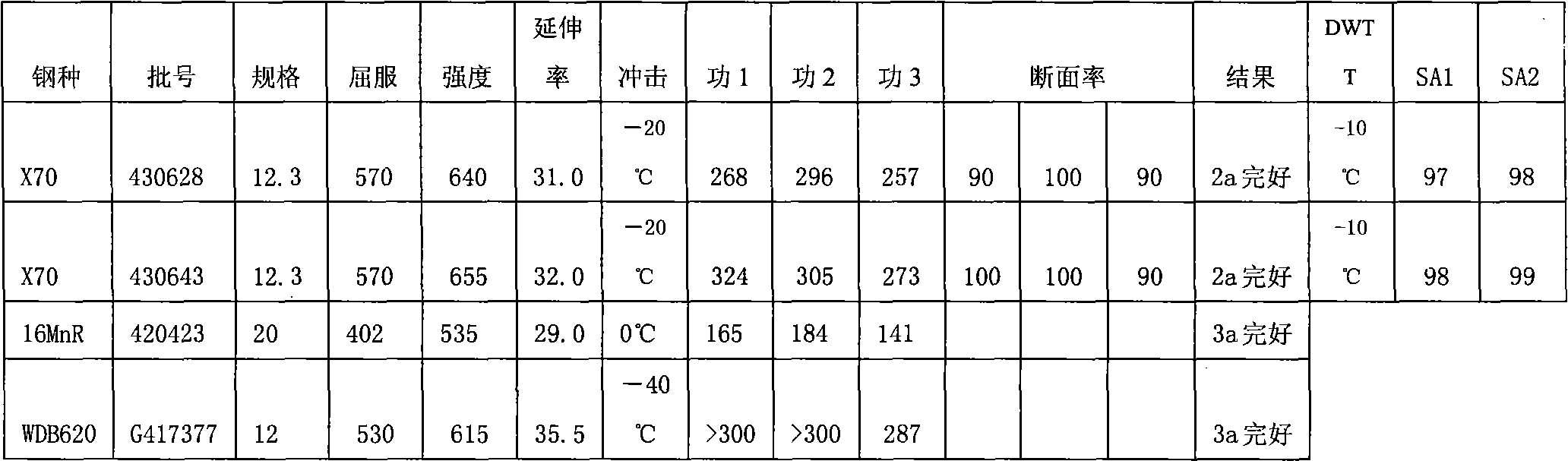

Examples

Embodiment 1

[0024] The normalizing furnace low temperature preheating flattening method of the present invention comprises the following steps:

[0025] (1) In this embodiment, the heating temperature of the normalizing furnace of steel based on bainite is 450° C., and the total heating time is 1.2 minutes / mm (this process is applicable to all steels based on bainite);

[0026] (2) When the steel plate is fed into the furnace, the method of slow loading and fast exit is adopted. The furnace loading speed is set at 0.007m / s, and the furnace discharge speed is set at 0.5m / s, so that the steel plate can be straightened after being discharged from the furnace, and the flatness of the steel plate can be guaranteed. Before straightening, blow air to clean the iron sheet and other sundries on the surface of the steel plate, so as to avoid the pressing of the iron sheet of the steel plate and the normalization of pits and roll marks, so as to reduce unplanned occurrences.

Embodiment 2

[0028] The normalizing furnace low temperature preheating flattening method of the present invention comprises the following steps:

[0029] (1) In this embodiment, the heating temperature of the normalizing furnace of steel based on bainite is 500° C., and the total heating time is 1.2 minutes / mm (this process is applicable to all steels based on bainite);

[0030] (2) When the steel plate is fed into the furnace, the method of slow loading and fast exit is adopted. The furnace loading speed is set at 0.125m / s, and the furnace discharge speed is set at 0.5m / s, so that it is easy to straighten the steel plate after it comes out of the furnace, and ensure the flatness of the steel plate. Before straightening, blow air to clean the iron sheet and other sundries on the surface of the steel plate, so as to avoid the pressing of the iron sheet of the steel plate and the normalization of pits and roll marks, so as to reduce unplanned occurrences.

Embodiment 3

[0032] The normalizing furnace low temperature preheating flattening method of the present invention comprises the following steps:

[0033] (1) The heating temperature of the normalizing furnace for ferrite-based steel is 600°C, and the total heating time is 1.2 minutes / mm (this process is applicable to all ferrite-based steels);

[0034] (2) When the steel plate is fed into the furnace, the method of slow loading and fast exit is adopted. The furnace loading speed is set at 0.007m / s, and the furnace discharge speed is set at 0.5m / s, so that the steel plate can be straightened after being discharged from the furnace, and the flatness of the steel plate can be guaranteed. Before straightening, blow air to clean the iron sheet and other sundries on the surface of the steel plate, so as to avoid the pressing of the iron sheet of the steel plate and the normalization of pits and roll marks, so as to reduce unplanned occurrences.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com