Fume exhaust ventilator and range integrated machine

An all-in-one machine and range hood technology, applied in the direction of removing lampblack, household stoves, household appliances, etc., can solve the problems of no obvious effect, easy penetration of condensed oil droplets, oil leakage, etc., to achieve good oil leakage prevention, low cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

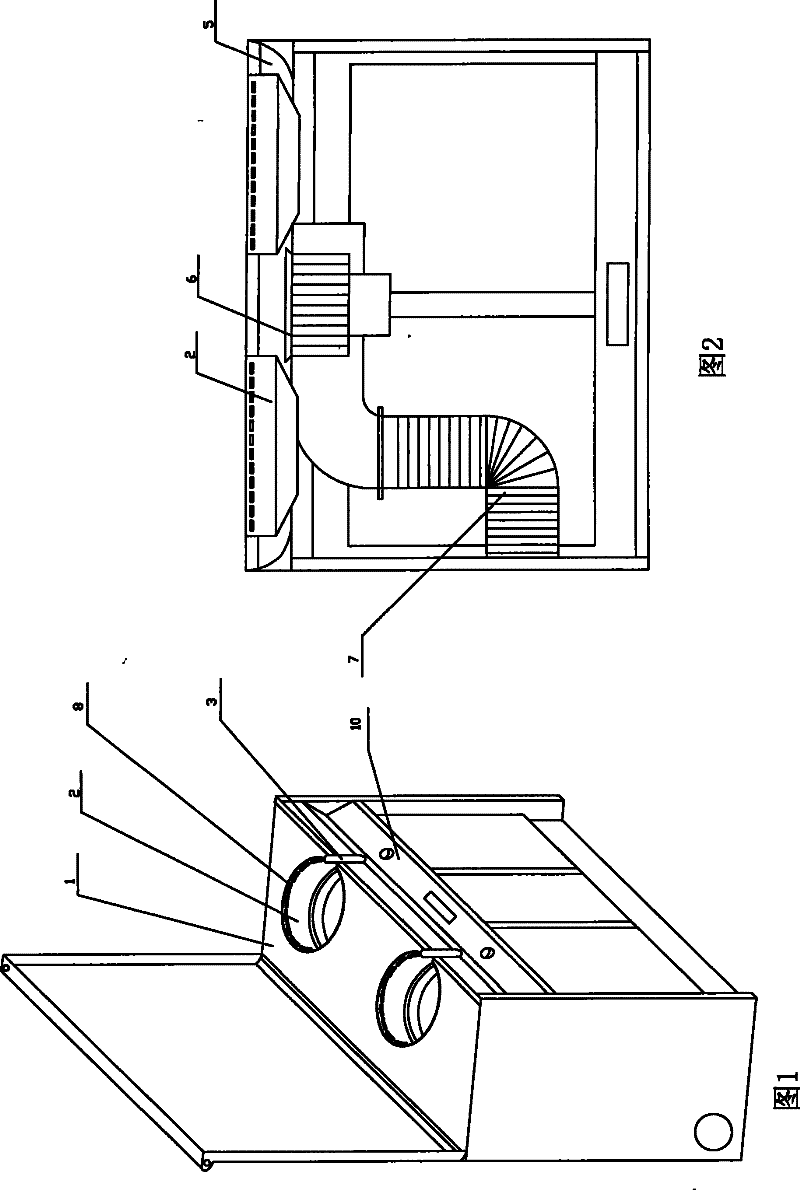

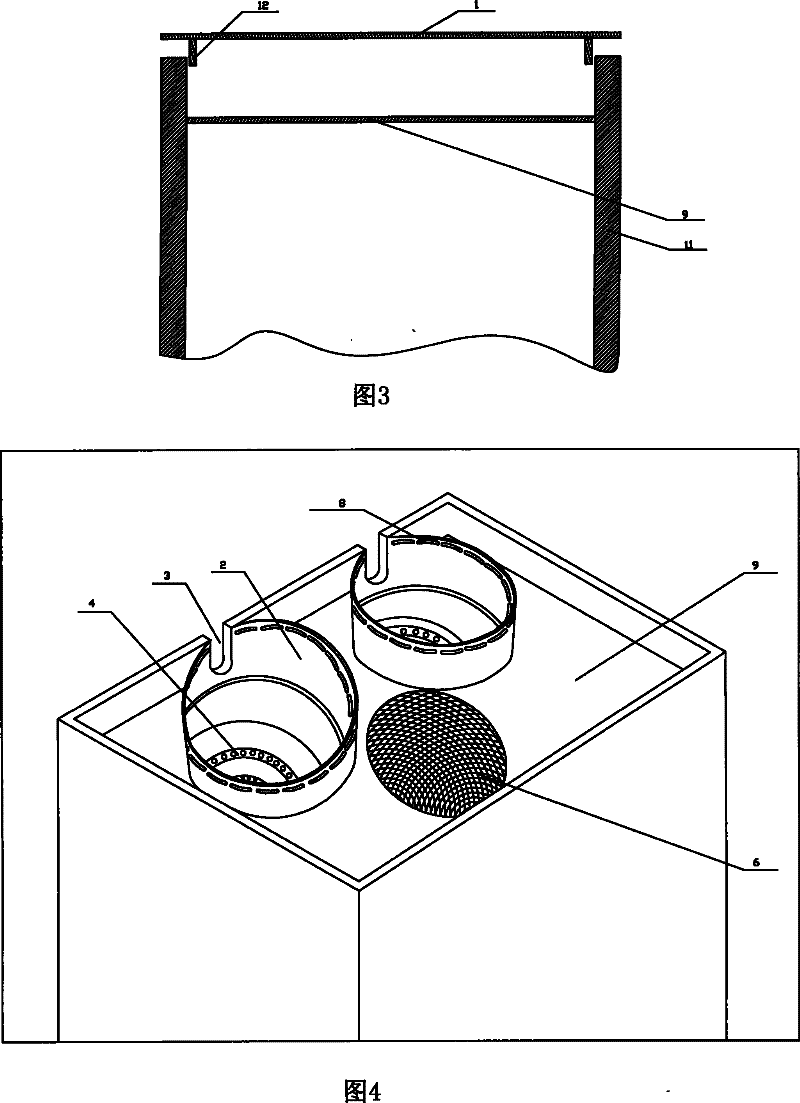

[0019] Refer to attached Figure 1-5 :

[0020] The range hood integrated machine of the present invention includes a cabinet-type body, the panel 1 of the body is provided with a concave cylindrical stove hole 2, the bottom plate of the stove hole 2 is provided with a stove 4, and the bottom of the stove hole 2 The upper part of the wall surface is provided with an arc-shaped suction port 8, and the side of the stove hole 2 facing people has a handle hole 3, the suction port 8 is covered in the gas collection box 5, and the air inlet of the fan 6 is arranged on the gas collection box. In the box 5, the wall surface of the stove hole 2 is connected with the top plate and the bottom plate of the gas collection box 5, the fan 6 is also connected with the exhaust pipe 7, and the top surface of the gas collection box 5 is attached with a The bar 12 of the junction of 11.

[0021] There is a bottom plate 9 generally parallel to the panel 1 , and the bottom plate 9 extends to the ...

Embodiment 2

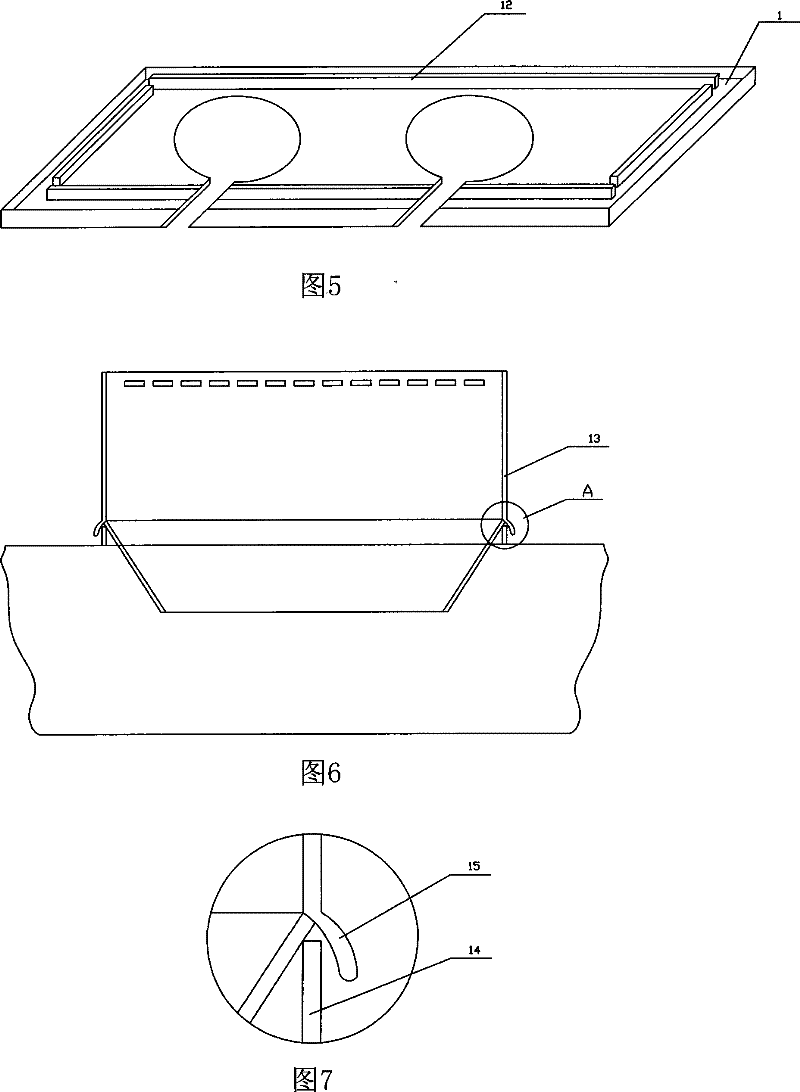

[0029] Refer to attached Figure 1-7 :

[0030] The difference between this embodiment and the second embodiment is that the following structure is added: the cylindrical wall surface 13 of the stove hole 2 is fastened with the annular flange 14 on the bottom plate 9, and the cylindrical wall surface 13 is wrapped in the The convex edge 14 is outside.

[0031] Oil droplets will also condense on the cylindrical wall surface 13 of the stove hole 2, and if the joint between the cylindrical wall surface 13 of the stove hole 2 and the bottom plate is exposed, it is also easily penetrated by oil. Adopting the structure of this embodiment can prevent the seams from contacting oil droplets and prevent leakage.

Embodiment 3

[0033] Refer to attached Figure 1-7 :

[0034] The difference between the present embodiment and the third embodiment is that the air outlet on the stove hole is added: the upper part of the wall of the stove hole 2 is provided with a positive pressure air outlet, and the air outlet is opposite to the suction port, and the air outlet is obliquely Next, the air outlet is connected to the positive pressure air source through the air duct.

[0035] The combined use of the blowing port and the suction port is conducive to the formation of a fluid envelope above the source of oil fume, improving the rate of oil fume absorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com