Static voltmeter correcting assembly, making method thereof and correcting method thereof

A technology of static voltage and assembly, applied in the field of correction assembly of static voltmeter, can solve the problems of no more accurate correction method, low accuracy, accumulation of static electricity in process machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Since the present invention discloses a static voltage detector calibration assembly, the basic principles of static voltage measurement, production and calibration used therein have been understood by those with ordinary knowledge in the relevant technical field, so the following description, No longer fully described. At the same time, the drawings compared below are schematic structural representations related to the features of the present invention, and are not and need not be completely drawn according to actual sizes, and are explained here in advance.

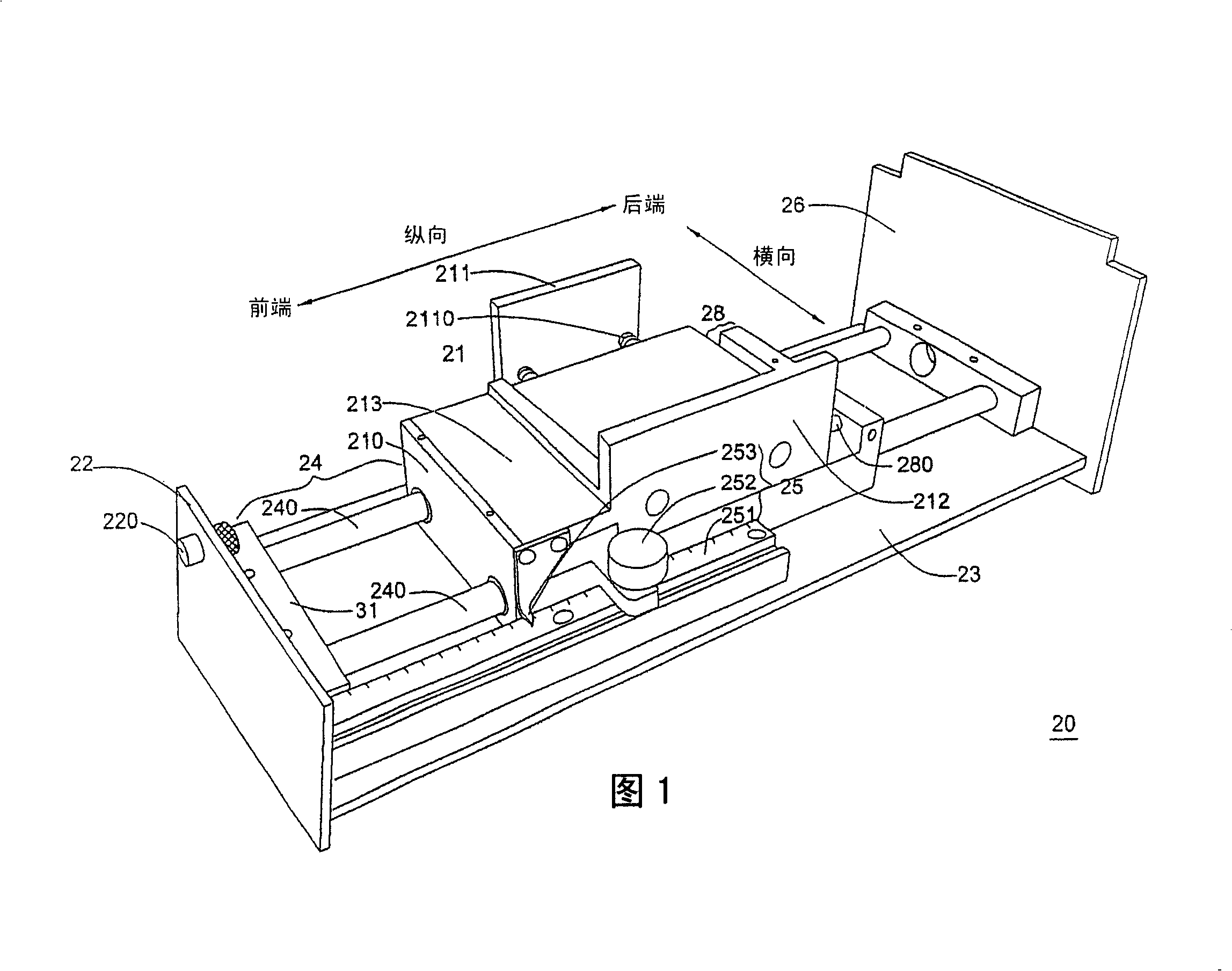

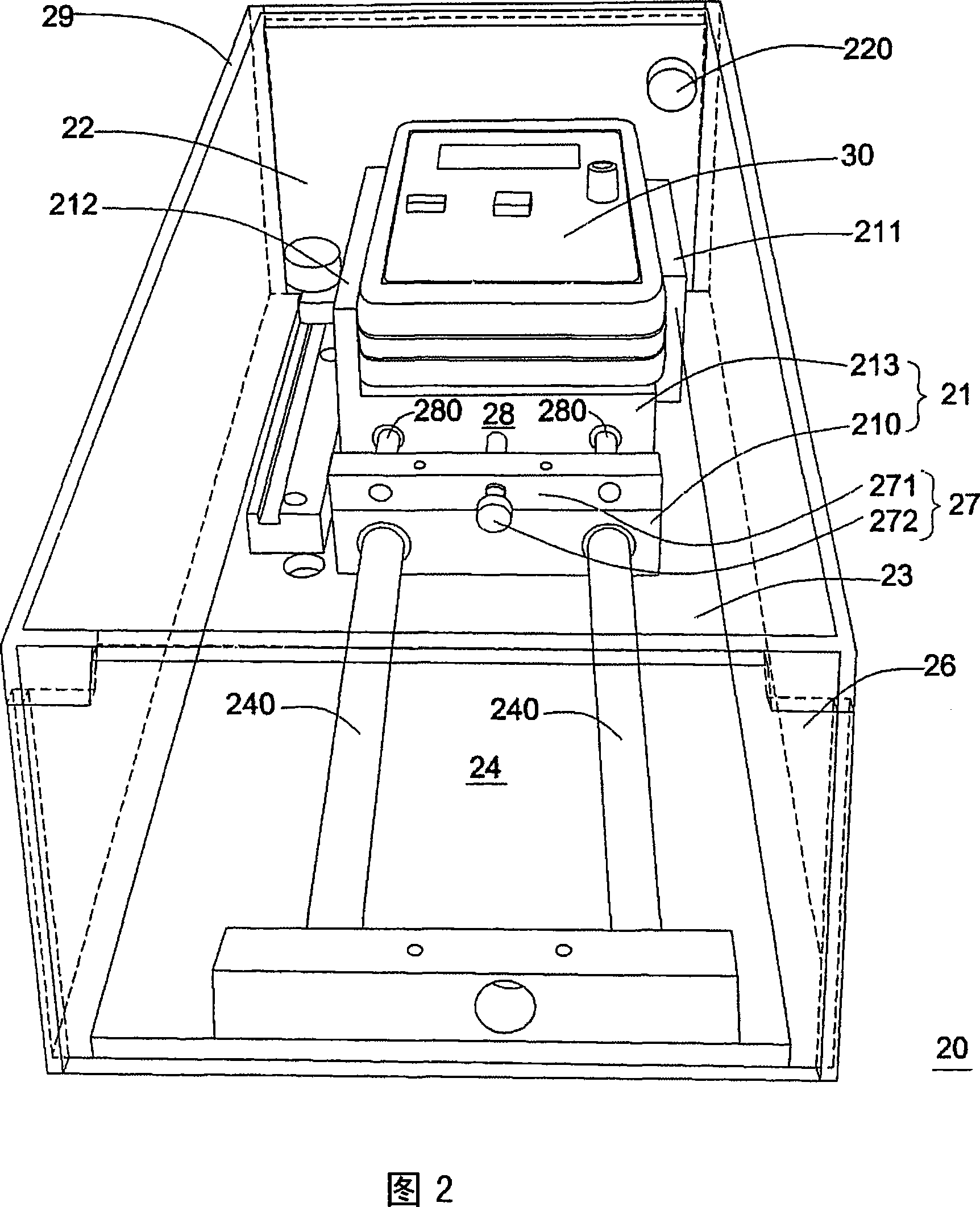

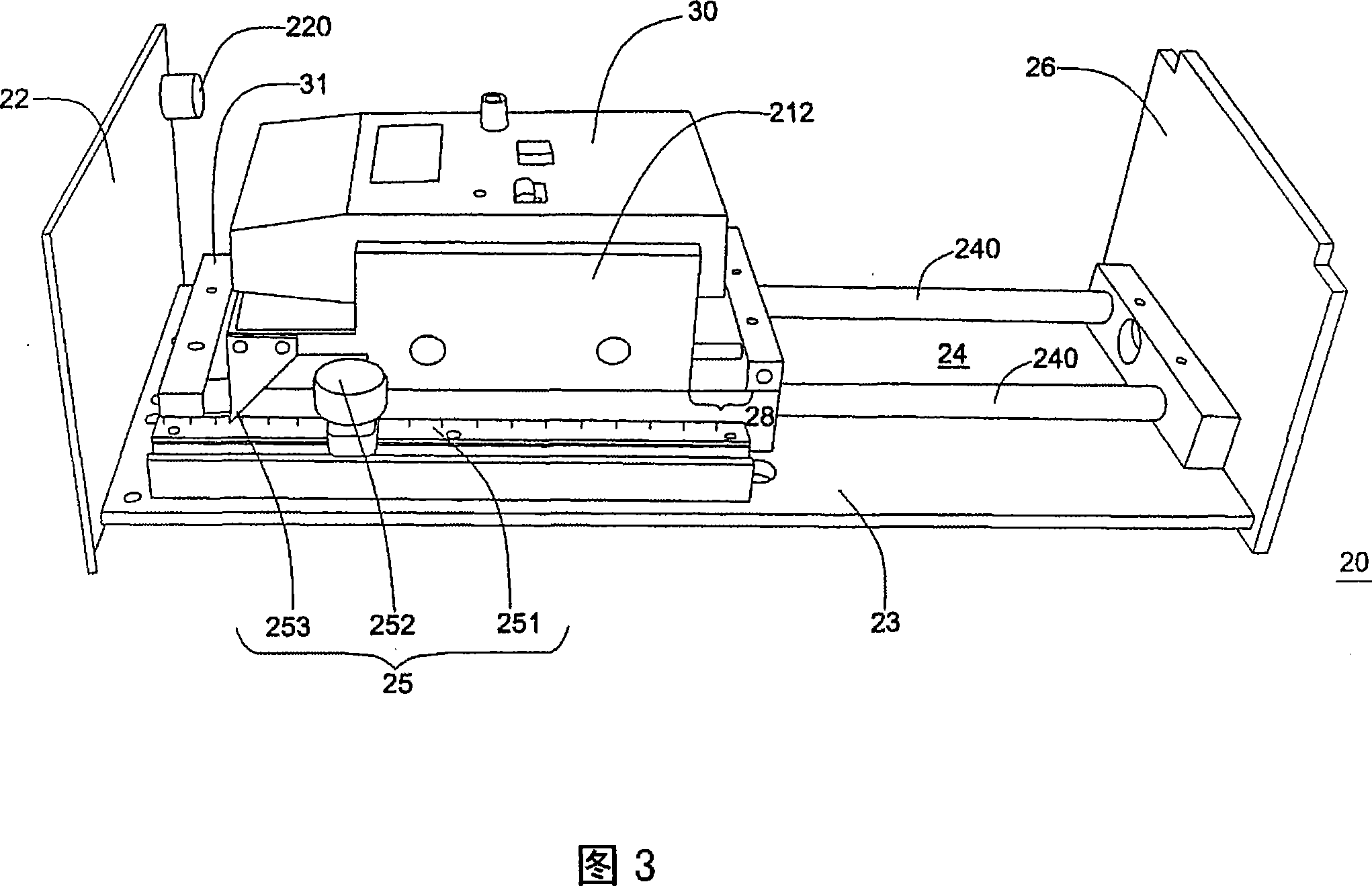

[0046] Please refer to FIG. 1, which is a first preferred embodiment provided according to the present invention, which is a calibration assembly 20 for a static voltage meter 30, including a clamping part 21, a high voltage plate 22, a bottom plate 23, and a first slide rail part 24, a scale part 25, a fine adjustment part 27, a second slide rail part 28 and an outer cover part 29. The holding part 21 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com