Method for purifying hypericin

A technology of hypericin and process, which is applied in the fields of quinone separation/purification, organic chemistry, pharmaceutical formulation, etc., and can solve problems such as failure to effectively separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

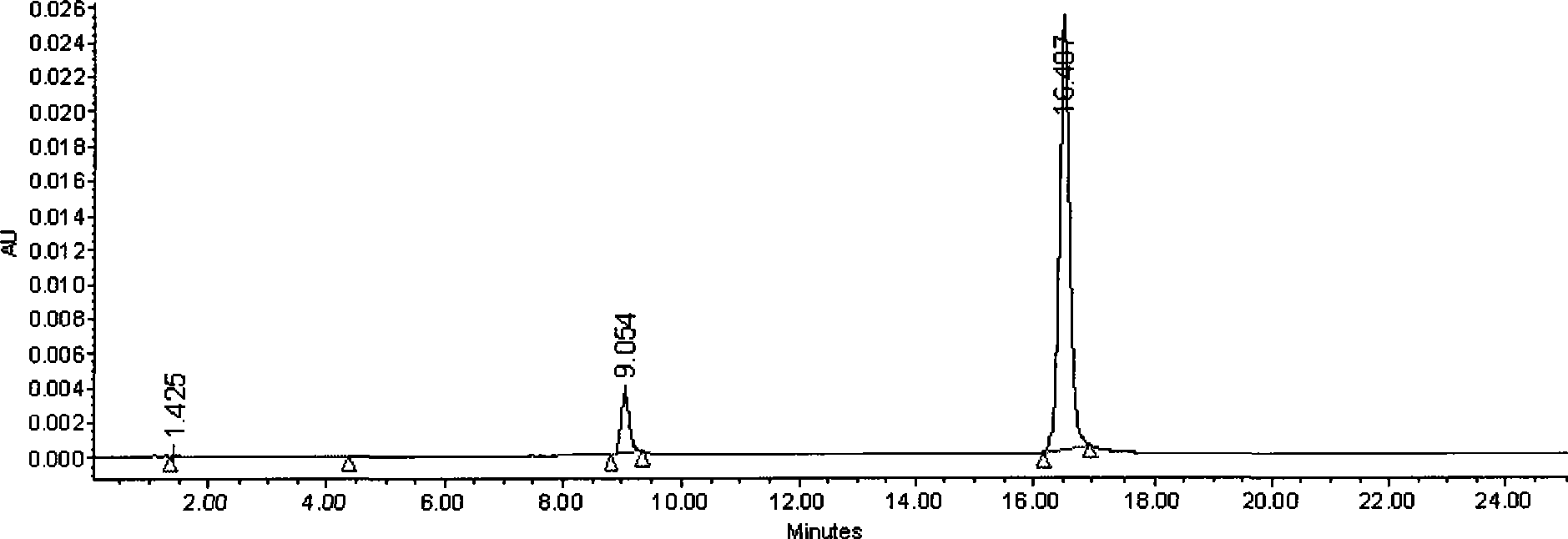

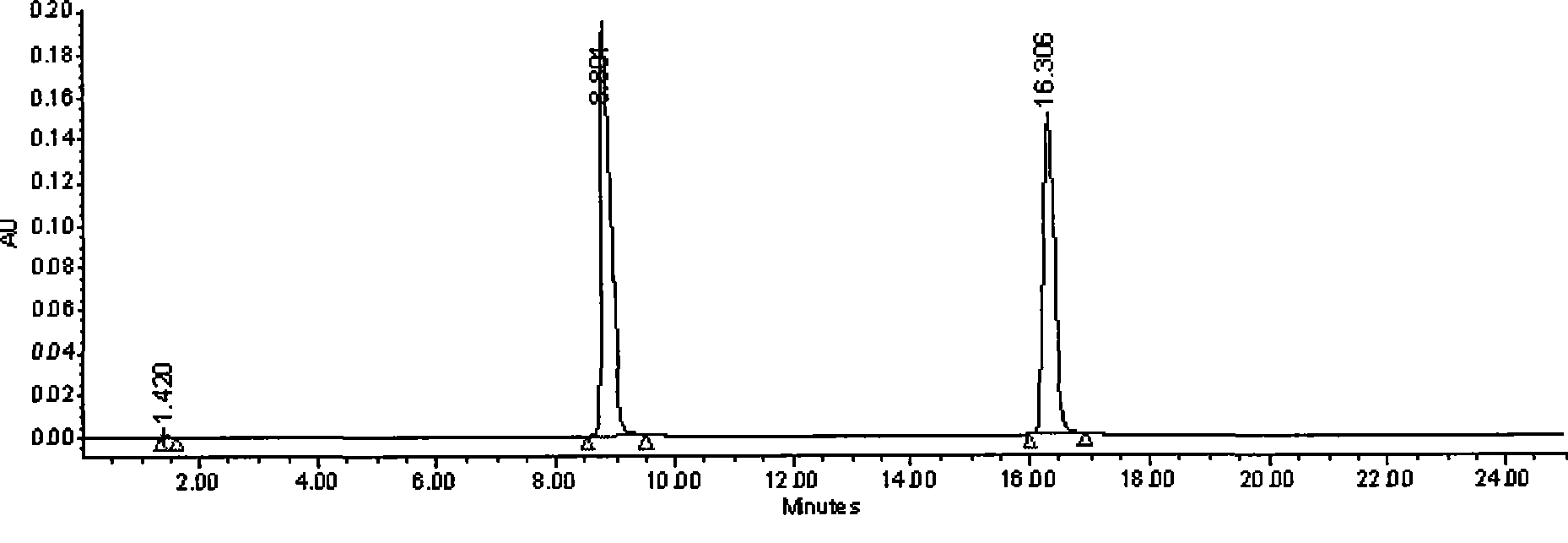

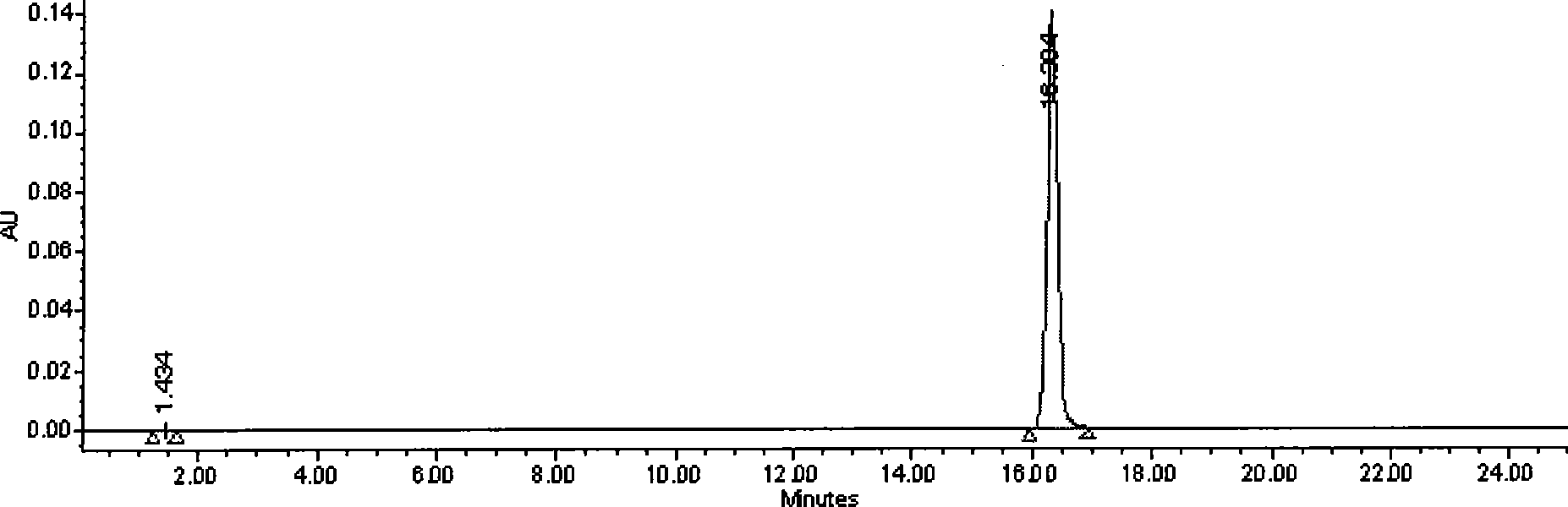

Image

Examples

Embodiment 1

[0057] A. Extraction and enrichment:

[0058] Take 500g of the above-ground parts of Hypericum perforatum with flowers, grind it, and extract 3 times under reflux with 75% ethanol at 80°C. Press to recover the solvent, add water and ethanol to dilute to 4 times the weight of the medicinal material, and adjust to 50% alcohol content, mix well, and centrifuge to obtain a supernatant; soak the macroporous adsorbent resin with 95% ethanol for 24 hours and then pack it into a column to Wash the column with 95% ethanol until the effluent is no longer turbid after adding water; wash with distilled water until there is no alcohol smell; the supernatant is passed through the D-101 macroporous adsorption resin that has been pretreated above, and the amount of resin is 1% of the volume of the supernatant. / 5, stop loading the sample after the resin is saturated; elute with 2 times the volume of the resin, and discard the washing liquid; then elute with 40% ethanol, and discard the eluent...

Embodiment 2

[0068] A. Extraction and enrichment:

[0069] Take 1000g of the crude extract of Hypericum perforatum, add acetone to percolate and extract until it is colorless, recover the solvent under reduced pressure at 55°C, add ethanol to dissolve, filter off the precipitate, dilute the supernatant with water and ethanol to 8 times the weight of the medicinal material, and adjust to The alcohol content is 15%, mix well, and centrifuge to obtain the supernatant; soak the macroporous adsorption resin in 95% ethanol for 24 hours, then pack the column, wash the column with 95% ethanol until the effluent is no longer turbid after adding water. Wash with distilled water until there is no alcohol smell; the supernatant is passed through the pretreated HZ-816 macroporous adsorption resin, the amount of resin is 1 / 4 of the volume of the supernatant, and the sample is stopped after the resin is saturated; use 1 times the resin volume of water for elution, discarding the washing solution; followe...

Embodiment 3

[0079] A. Extraction and enrichment:

[0080] Take 200g of Hypericum perforatum, add methanol and ultrasonically extract until it is colorless, recover the solvent under reduced pressure at 40°C, add ethanol to dissolve, filter off the precipitate, dilute the supernatant with water and ethanol to 5 times the weight of the medicinal material, and adjust to the alcohol content Mix and centrifuge to obtain a supernatant; soak the macroporous resin in 95% ethanol for 24 hours, then pack the column, and wash the column with 95% ethanol until the effluent is no longer turbid after adding water. Wash with distilled water until there is no alcohol smell; the supernatant is passed through the pretreated LSI-106 macroporous adsorption resin, the resin volume is 1 / 5 of the volume of the supernatant, and the sample is stopped after the resin is saturated; use 1.5 times the resin volume of water for elution, discarding the washing solution; followed by elution with 30% ethanol, discarding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com