Thermoplastic polyurethane elastomer with hydrolytic stability and preparation method thereof

A thermoplastic polyurethane and elastomer technology, which is applied in the field of thermoplastic polyurethane elastomer and its preparation, can solve the problems of complex production process, high price, and increased production cost, so as to improve product competitiveness, improve hydrolysis resistance, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

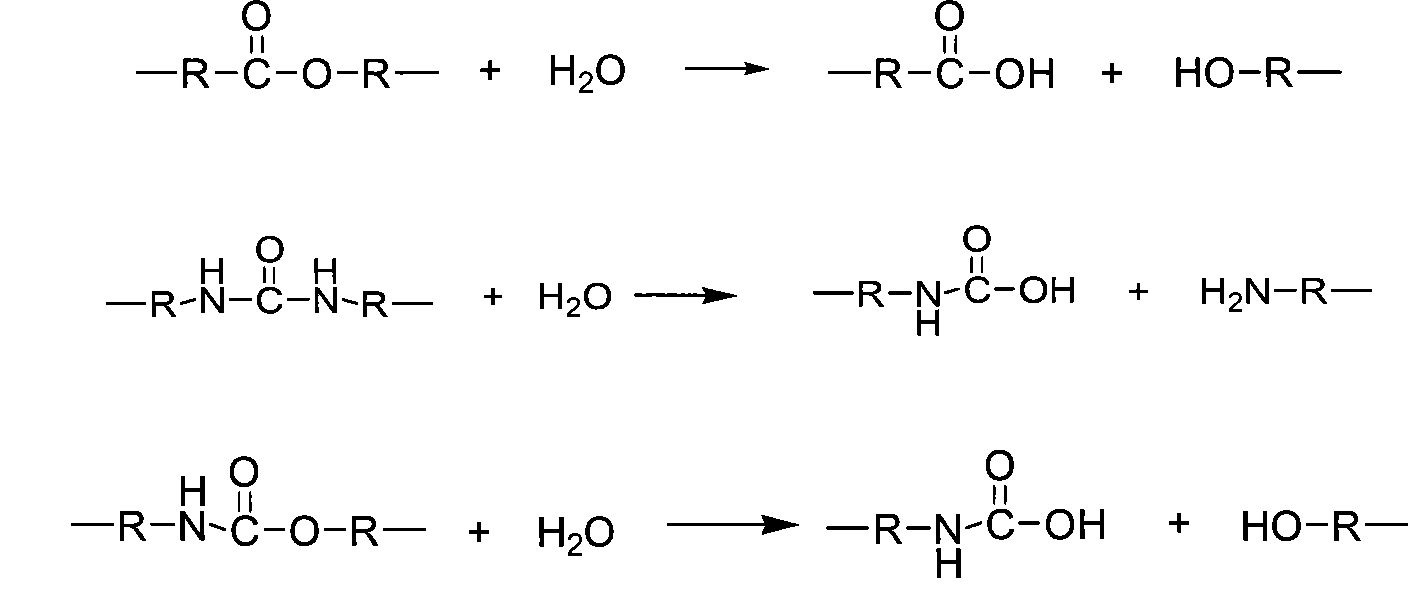

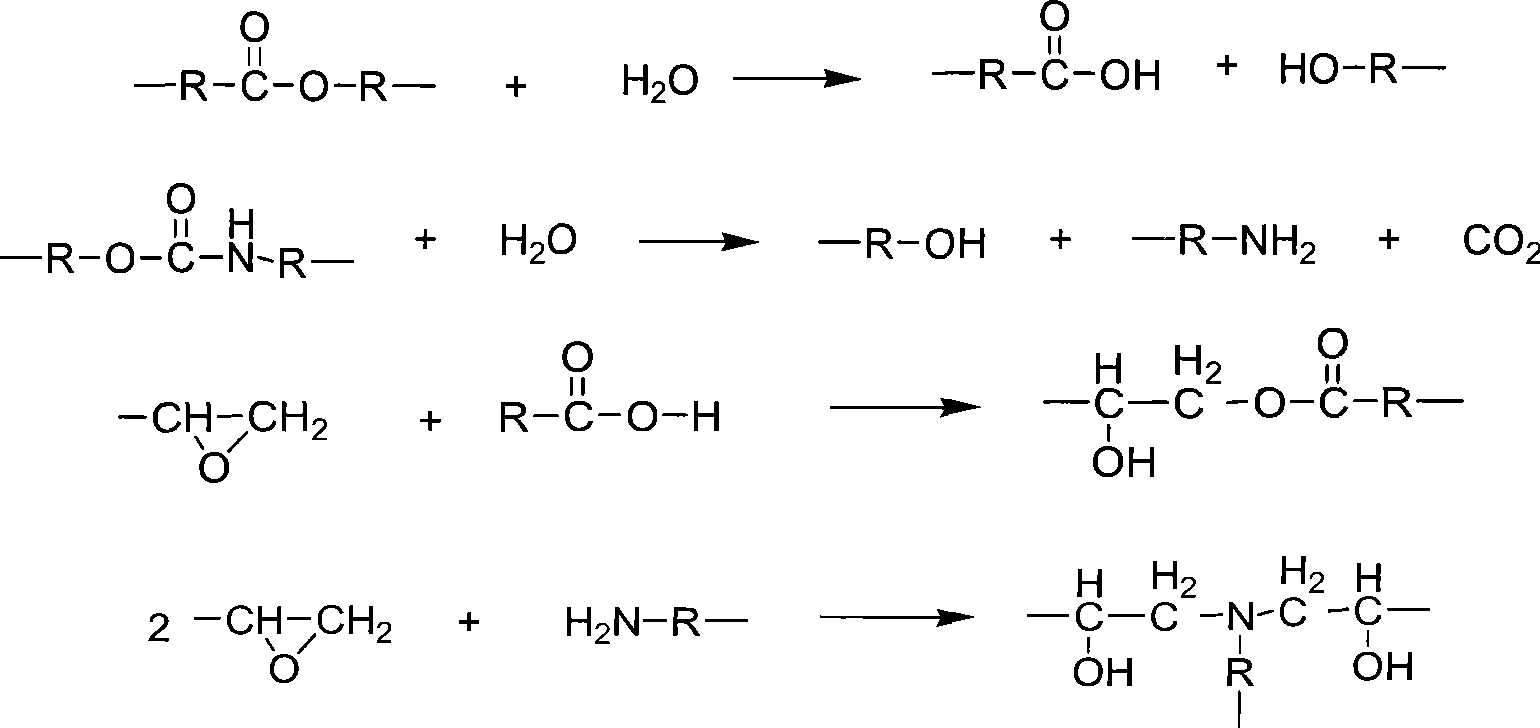

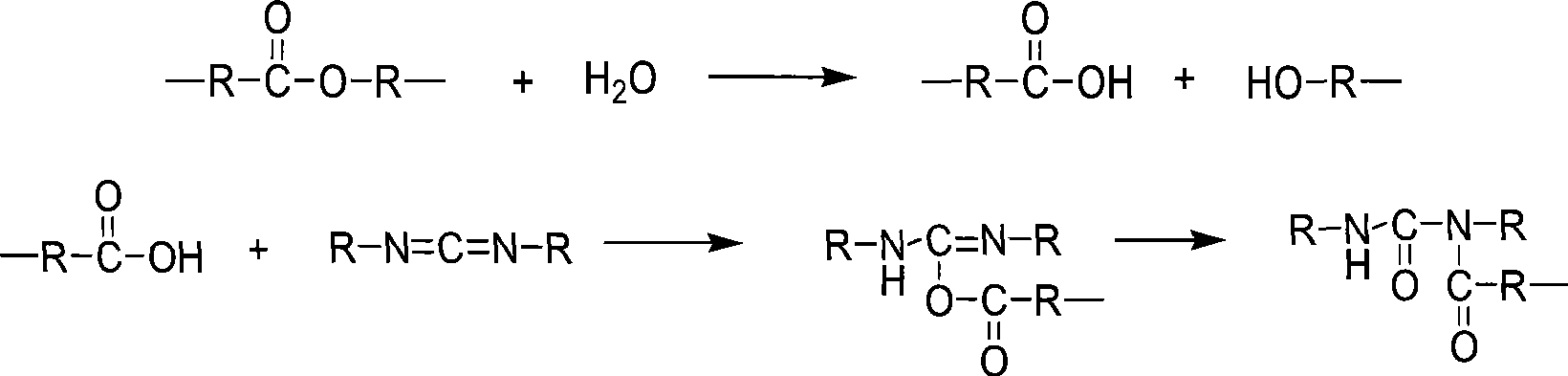

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Polyester type thermoplastic polyurethane elastomer

[0037] Add 0.785 kilograms of liquefied MDI to 7.065 kilograms of pure MDI and mix evenly, then with 68.25 kilograms of polyester diol (molecular weight 2000), 23.90 kilograms of chain extender (1,4-butanediol), an appropriate amount of Add stannous octoate to a twin-screw reaction extruder for reaction, directly granulate underwater, and obtain TPU granules after drying and aging.

Embodiment 2

[0038] Example 2 Polyether type thermoplastic polyurethane elastomer

[0039] Add 1.98 kilograms of liquefied MDI to 31.06 kilograms of pure MDI and mix well, then mix with 60.29 kilograms of polyether glycol (PTMEG, molecular weight 1000), 6.63 kilograms of chain extender (1,4-butanediol), Add appropriate amount of stannous octoate (T-9) into a twin-screw reaction extruder for reaction, directly granulate under water, and obtain TPU granules after drying and aging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com