Installation method for special-shaped arch shell type construction network frame

An installation method and network frame technology, which are applied in the direction of buildings, building components, building structures, etc., can solve the problems of complex shapes, difficult control of installation accuracy, and many high-altitude assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

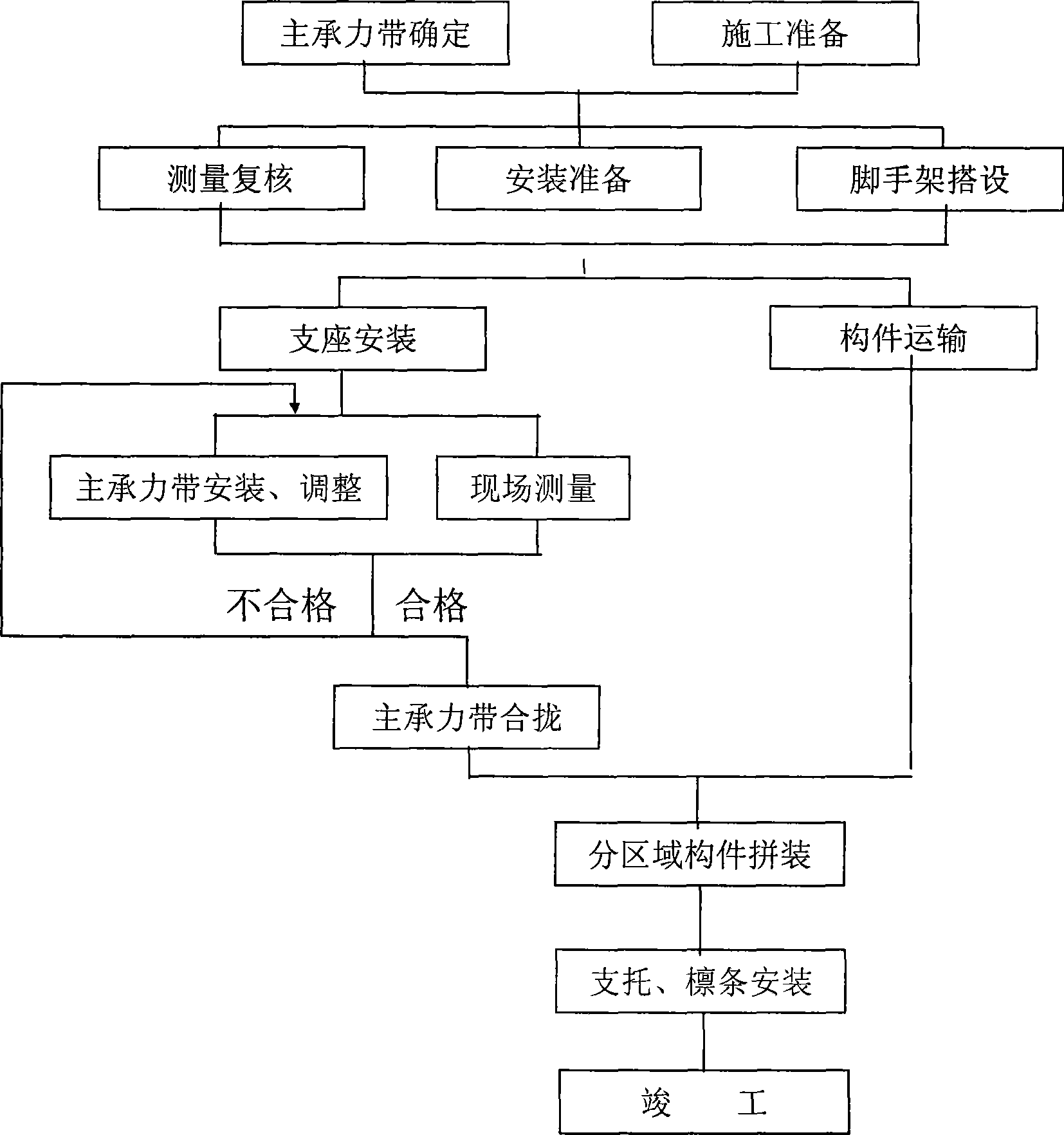

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiment of the gymnasium is used to illustrate the installation method of a special-shaped arched shell building grid in the present invention. The shape of the engineering roof is four petals symmetrically distributed along the X and Y axes, and each petal is composed of two sub-spheres. The grid structure is located on 24 supports, and the axis of the supports is distributed in an ellipse, with a maximum span of 57.04m×70.2m. The span of four main bearing supports is 47m×57.04m, and 20 auxiliary supports are rubber supports. seat. The height of the column tops ranges from 7.4m to 19.8m. The grid structure is a triangular pyramid system, and the height of the grid ranges from 2.0m to 2.3m. The highest ridge of the net frame is 25.15m. The net frame is located on the third floor of the gymnasium, and the center is the second-floor basketball court. The manufacture of grid components mainly includes: bolt balls, rod combinations, supports, etc. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com