Constant velocity universal joint drive spindle assembly clearance test stand

A technology of constant velocity universal joints and drive shafts, which is applied in the field of mechanisms in the field of automotive engineering technology, and can solve the problems of not testing workpieces with different structures or lengths, not testing the axial clearance of fixed ends, and not reflecting the circumferential clearance of components, etc. , to achieve the effect of simple structure, wide application range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment is carried out under the premise of technical solution of the invention, has provided detailed embodiment and specific operation process, but protection scope of the present invention is not limited to the following the embodiment.

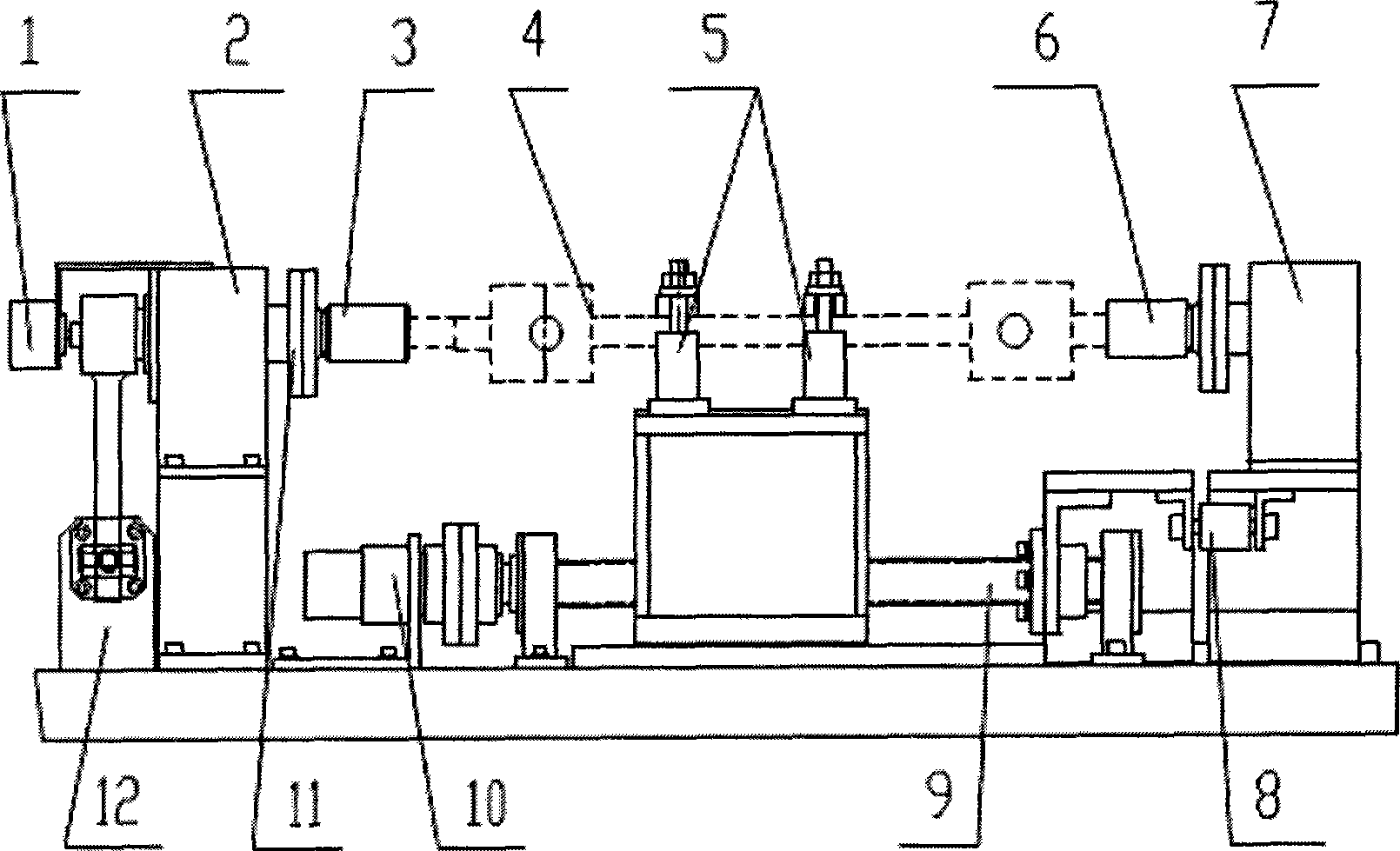

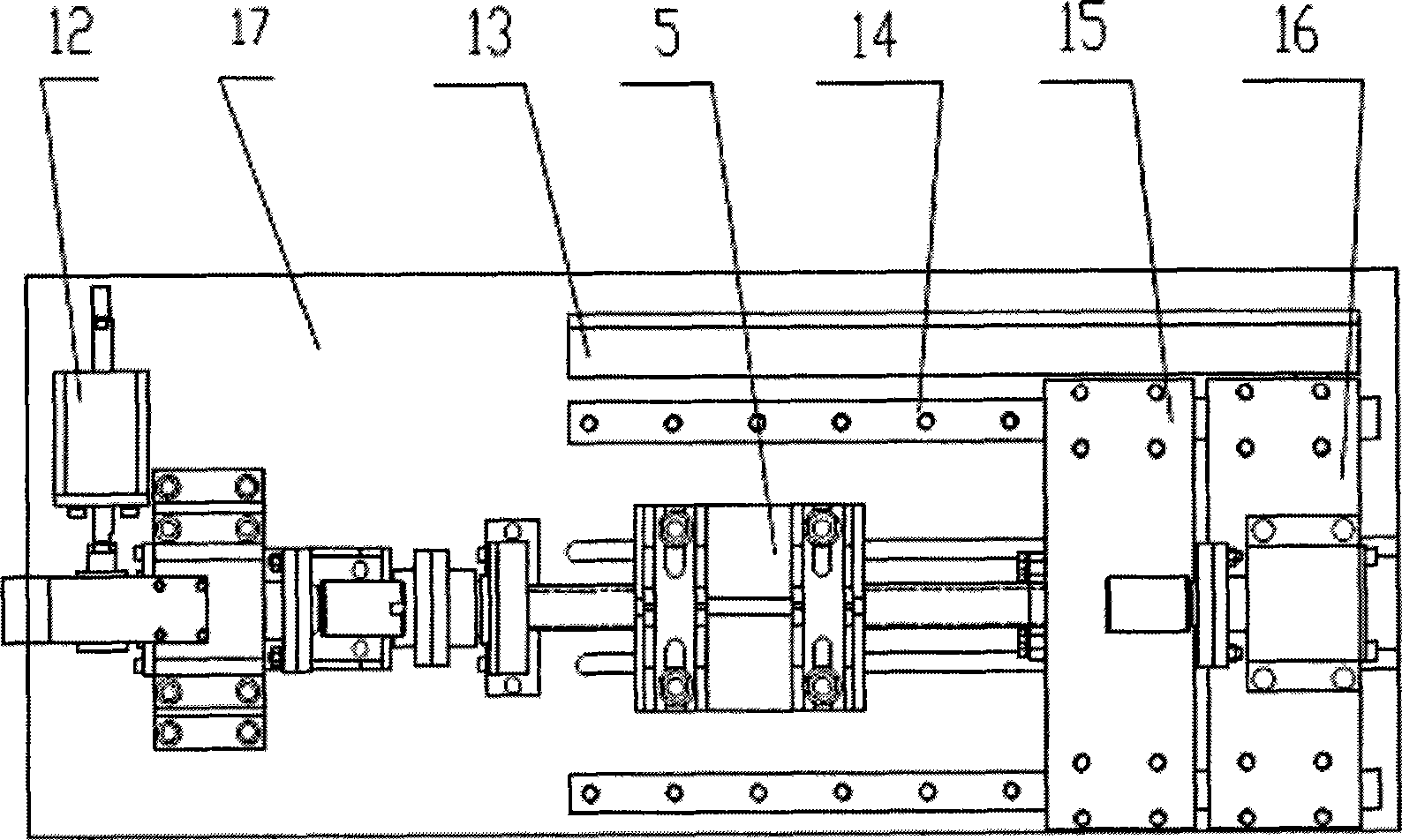

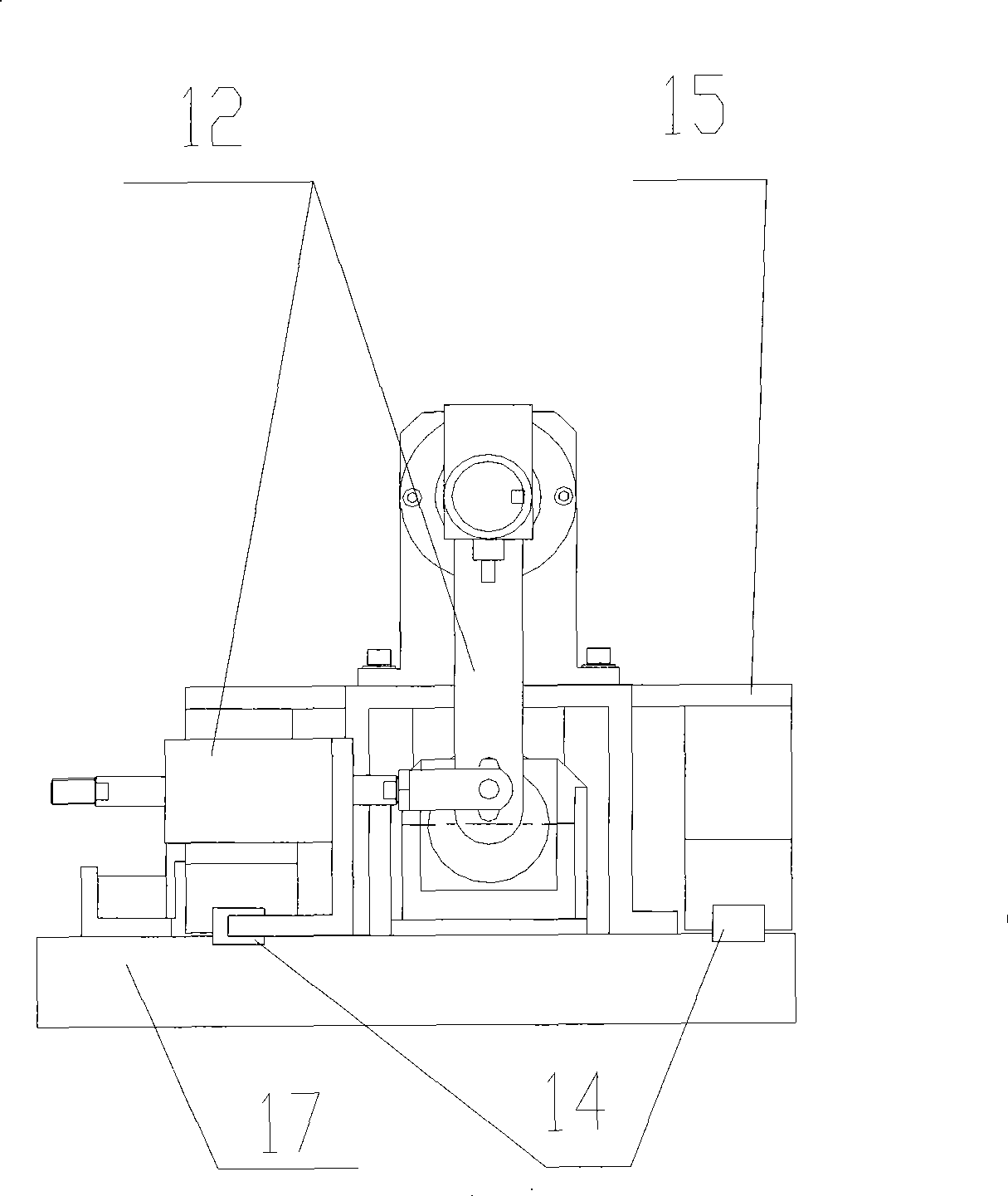

[0027] Such as figure 1 , 2 As shown in and 3, this embodiment includes: an angle sensor 1, a circumferential clearance test bearing seat 2, a circumferential clearance test chuck 3, a fixture 5, an axial clearance test chuck 6, an axial clearance test bracket 7, and a tension pressure sensor 8 , linear transmission assembly 9, motor 10, circumferential gap test spindle 11, torque force assembly 12, displacement sensor 13, guide rail 14, front slide plate 15, rear slide plate 16, frame 17. Wherein: the angle sensor 1 and the circumferential clearance test chuck 3 are arranged respectively at the tail and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com