Electrode assembly, electric arc tube special for ceramic method halide lamp, and manufacturing method thereof

A technology of halide lamps and ceramic metals, which is applied in the manufacture of electrode systems, cold cathodes, and discharge tubes/lamps, etc. It can solve the problems of ceramic tailpipe bursting, reduced ignition reliability, and failure to cover ceramic tube bursts, etc. , to achieve the effect of prolonging the service life and improving the operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

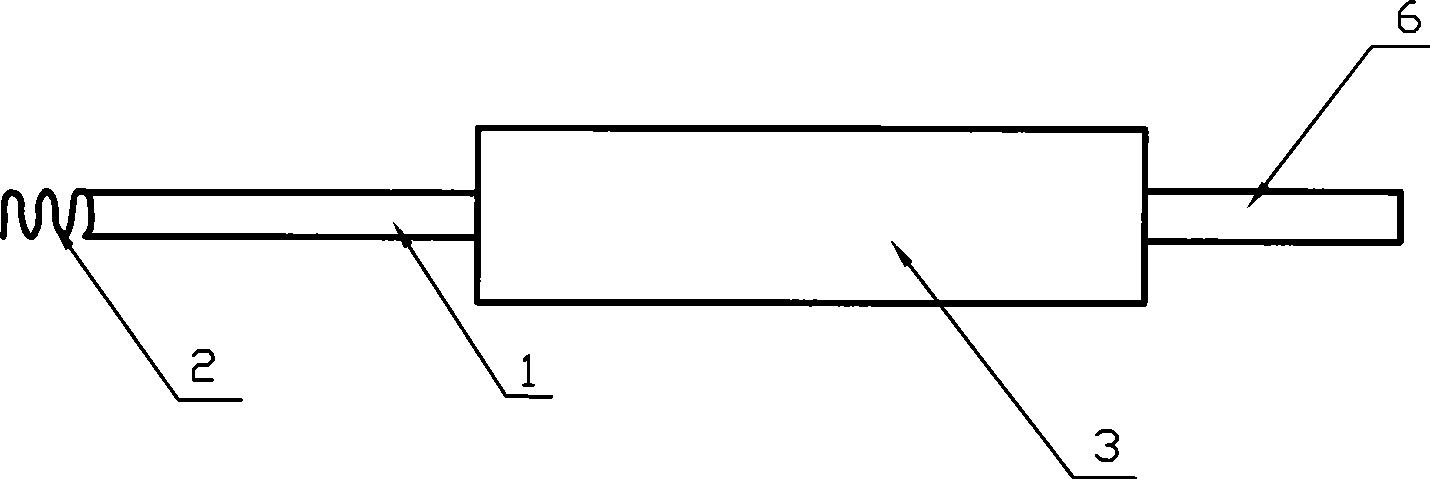

[0020] Embodiment 1: as figure 1 As shown, it is a structural schematic diagram of an embodiment of a special electrode assembly, including a tungsten electrode rod 1, a tungsten ring 2, a cermet rod 3, and a metal rod 6. The material of the cermet rod 3 is composed of alumina and molybdenum. The tungsten ring 2, the tungsten electrode rod 1, the cermet rod 3 and the metal rod 6 are respectively coaxially welded in sequence to form the whole electrode structure.

Embodiment 2

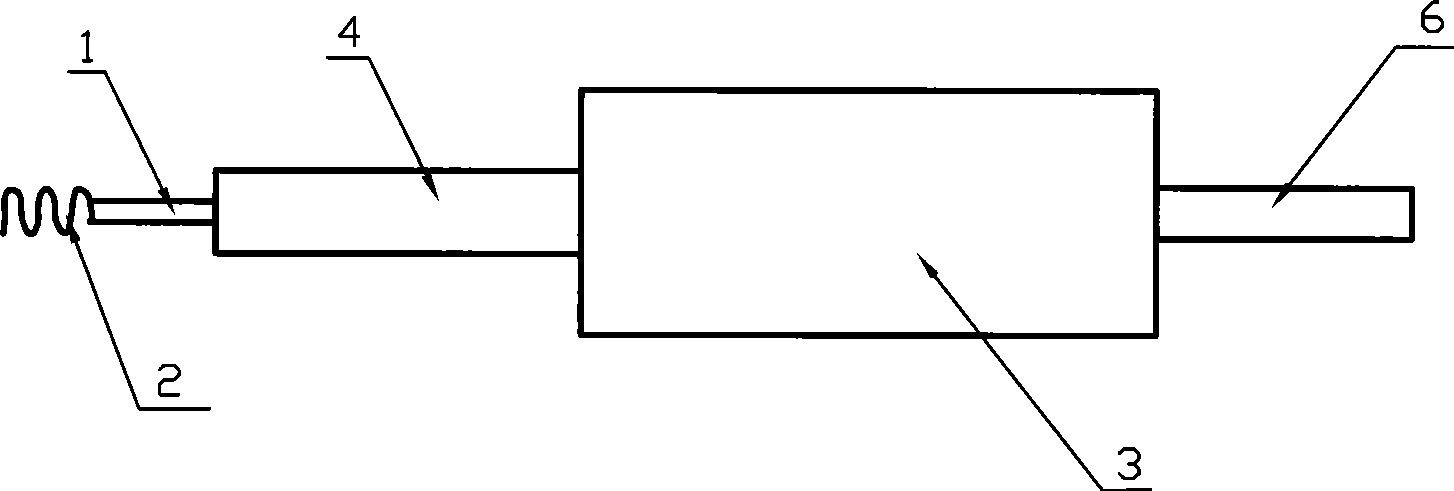

[0021] Embodiment 2: as figure 2 As shown, it is a structural schematic diagram of another embodiment of the special electrode assembly, including a tungsten electrode rod 1, a tungsten ring 2, a cermet rod 3, a tungsten rod 4, and a metal rod 6. The material of the cermet rod 3 is made of alumina and Molybdenum composition. The tungsten ring 2, the tungsten electrode rod 1, the tungsten rod 4, the cermet rod 3 and the metal rod 6 are respectively coaxially welded in sequence to form the whole electrode structure.

Embodiment 3

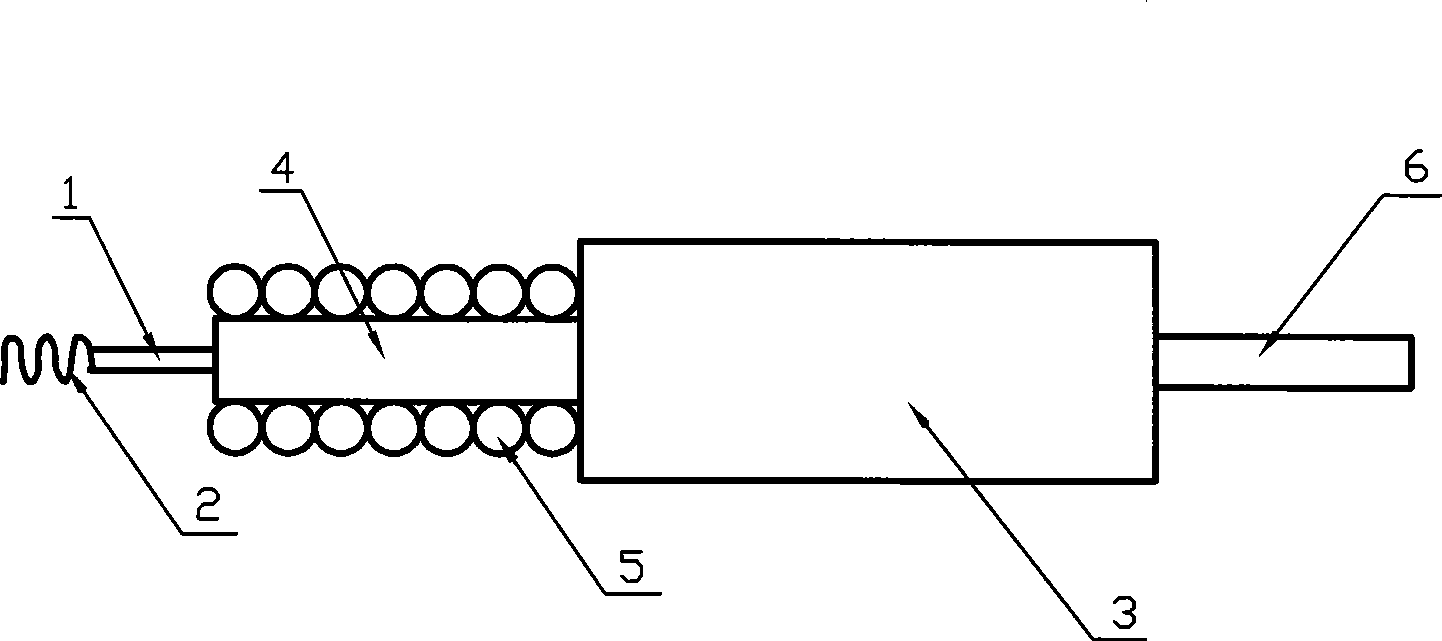

[0022] Embodiment 3: as image 3 As shown, it is a structural schematic diagram of another embodiment of the special electrode assembly, including tungsten electrode rod 1, tungsten ring 2, cermet rod 3, tungsten rod 4, molybdenum ring 5, metal rod 6, and the material of cermet rod 3 Composed of alumina and molybdenum. The molybdenum ring 5 is wound on the tungsten rod 4, and the tungsten ring 2, the tungsten electrode rod 1, the tungsten rod 4 equipped with the molybdenum ring 5, the cermet rod 3 and the metal rod 6 are respectively coaxially welded to form the whole electrode structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com