Manufacturing method for mask read only memory device

A manufacturing method, mask read-only technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effect of reducing process complexity, avoiding mixed use of machines, and avoiding logic process incompatibility problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical features of the present invention more comprehensible, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

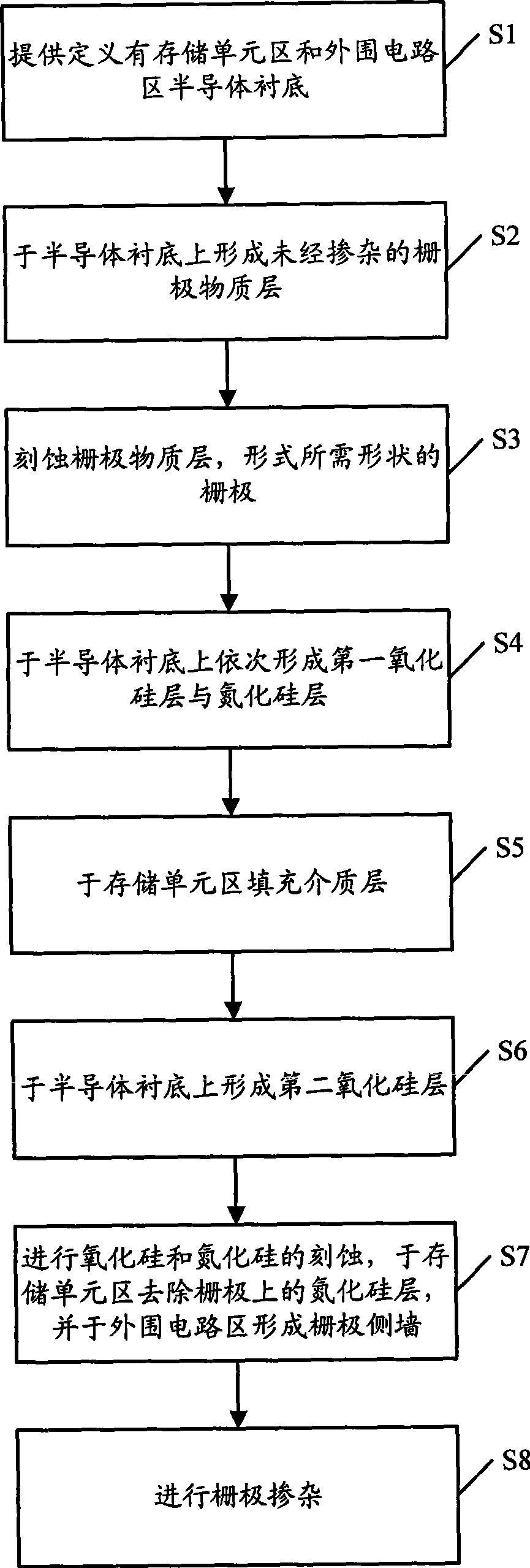

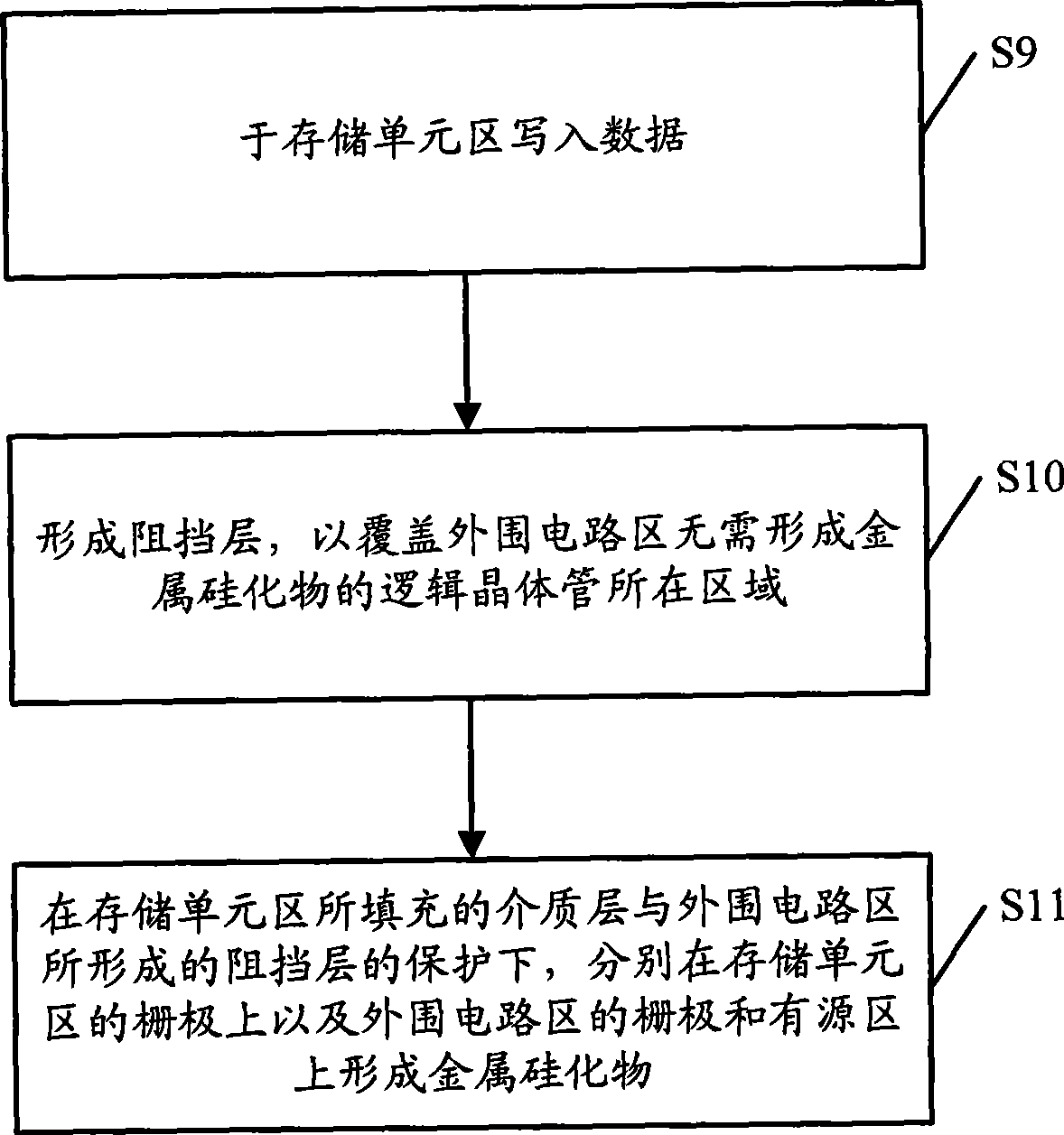

[0030] Please refer to figure 1 , which is a schematic flow chart of a mask ROM manufacturing method provided by an embodiment of the present invention. As shown in the figure, the manufacturing method of the mask ROM includes the following steps:

[0031] S1: Provide a semiconductor substrate defined with a memory cell area and a peripheral circuit area;

[0032] S2: forming an undoped gate substance layer on the semiconductor substrate;

[0033] S3: Etching the gate material layer to form a gate with a desired shape;

[0034] S4: sequentially forming a first silicon oxide layer and a silicon nitride layer on the semiconductor substrate;

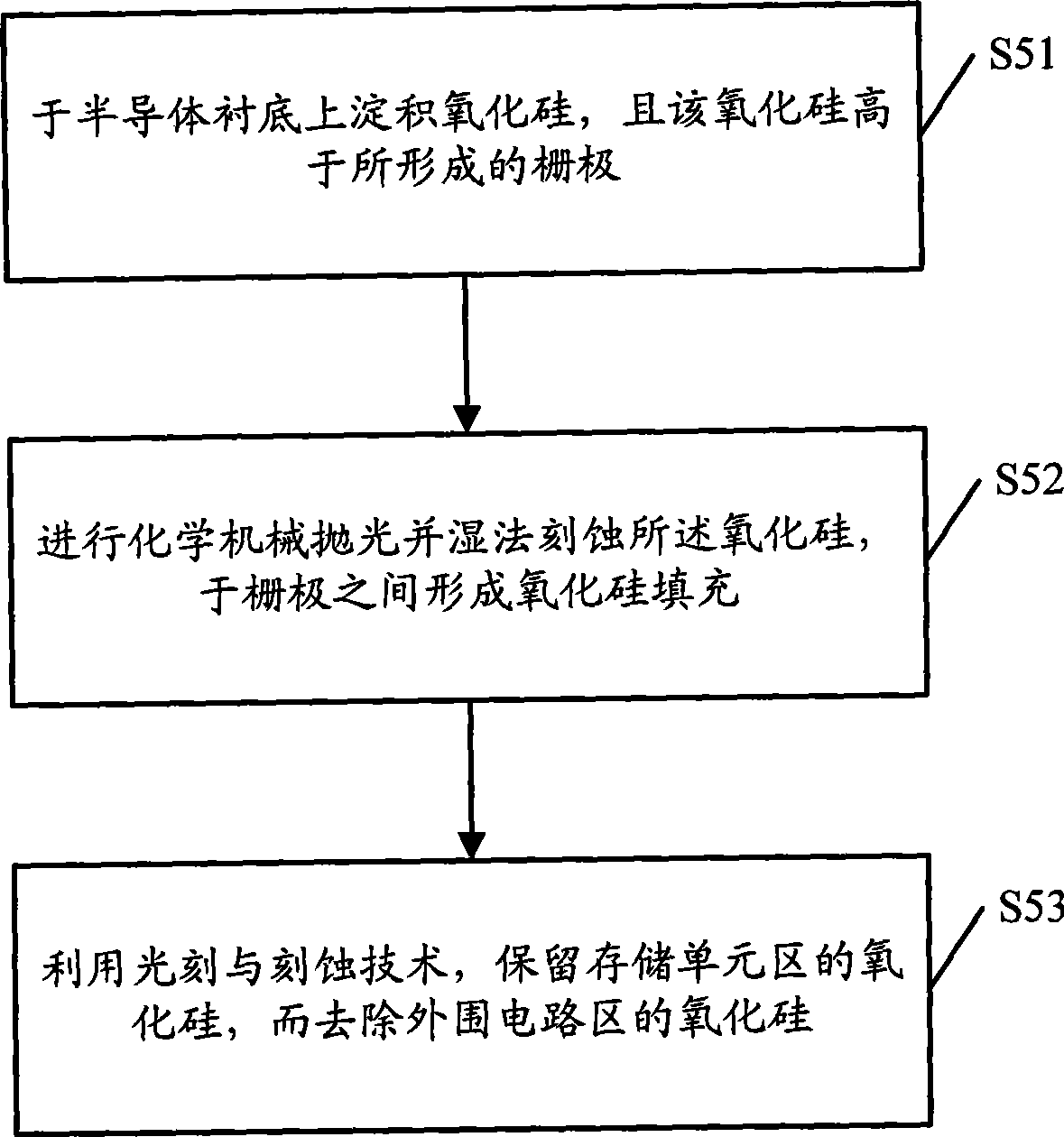

[0035] S5: filling the medium layer in the storage unit area;

[0036] S6: forming a second silicon oxide layer on the semico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com