Automatic ice melting method for multiple division electricity transmission line and special switch thereof

A transmission line and ice-melting method technology, which is applied to the installation of electrical components and cables, overhead installation, etc., can solve the problems of high cost, loss of load, high-power multi-split transmission line ice melting, etc., to reduce labor intensity and improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 Manual remote control automatic ice melting method

[0027] The ice-melting method of this embodiment is the same as the above-mentioned technical solution, and will not be repeated here. The structure and working principle of the special switch will be introduced in detail below.

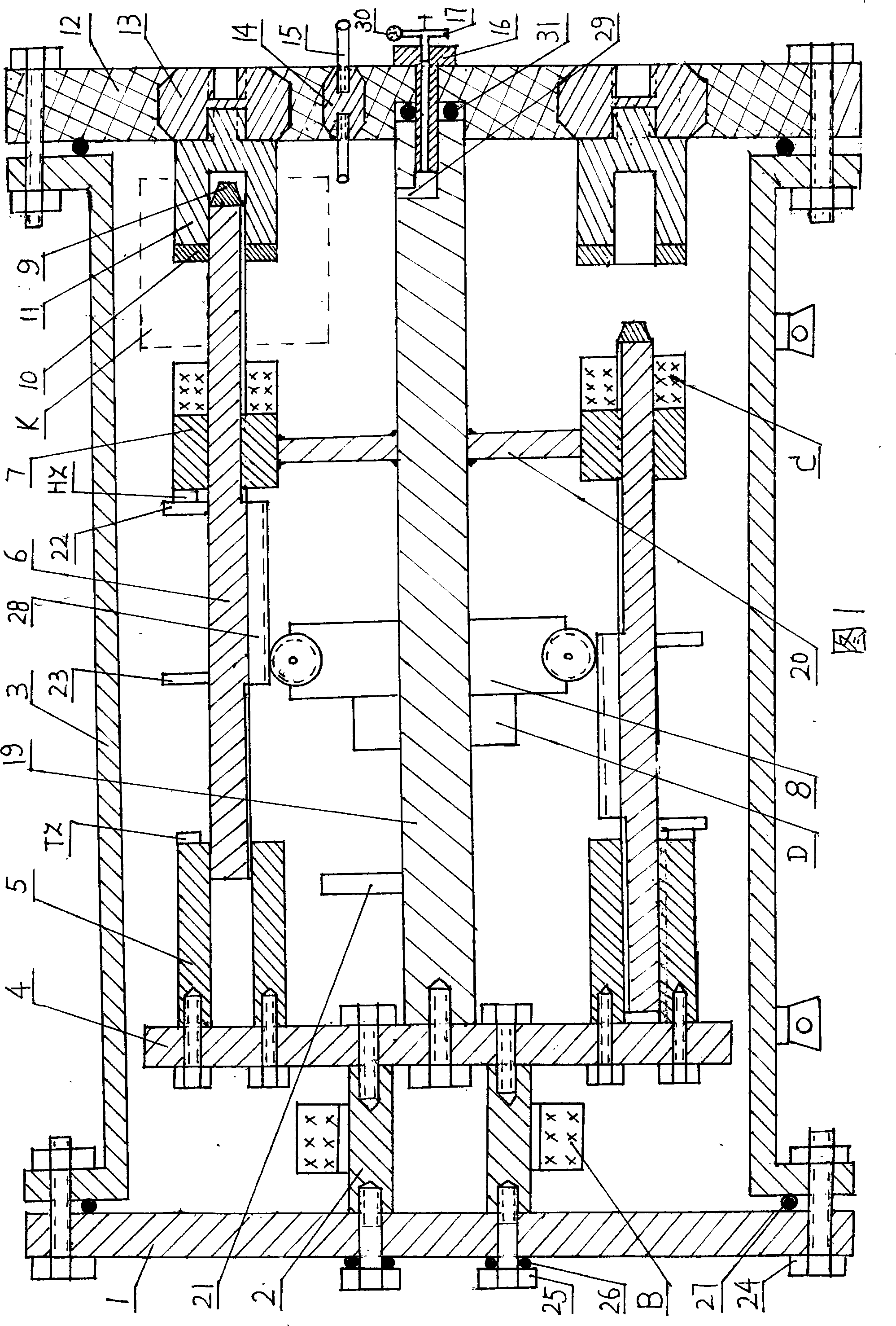

[0028] As shown in Figure 1, the drainage flange 1 and the insulating end cover 12 are respectively fixed on the flanges at both ends of the metal casing 3 through O-rings 27 and flange bolts 24, and one end of the square central column 19 is passed through an O-ring 31 And the inflation screw 16 is fixed on the insulating end cover 12, the three-way valve 17 is installed on the central hole of the inflation screw 16, and an outlet of the three-way valve 17 is equipped with a barometer 30, and the other outlet is an inflation and deflation interface, and the square center column 19 There is an air hole 29 at the end that communicates with the central hole of the inflation screw ...

Embodiment 2

[0032] Embodiment 2 Automatic ice melting method controlled by frost sensor signal

[0033] This embodiment is basically the same as Example 1, except that frost sensors and sub-conductor current source transformers for supplying power are respectively installed on the sub-conductors in the ice-melting section.

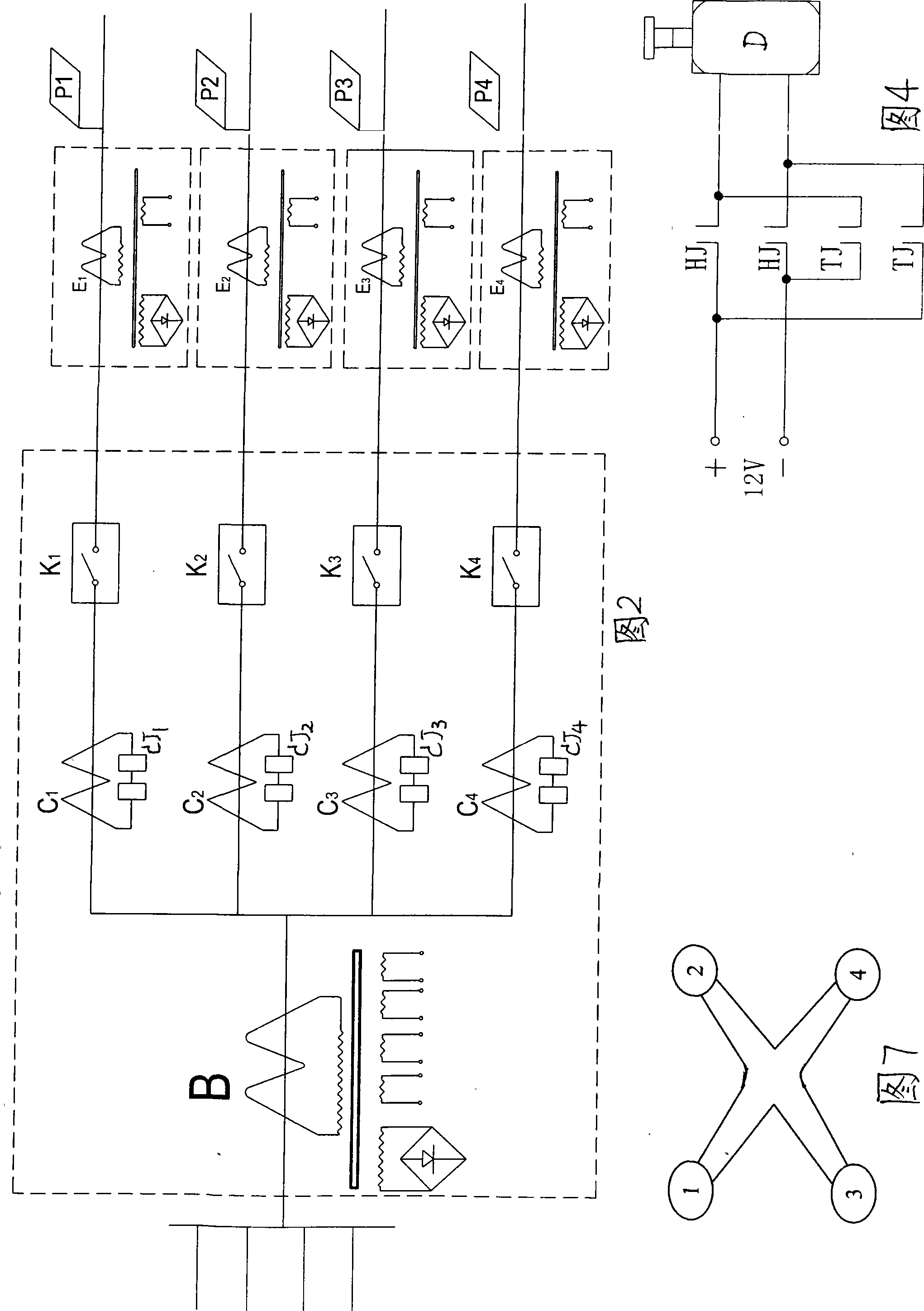

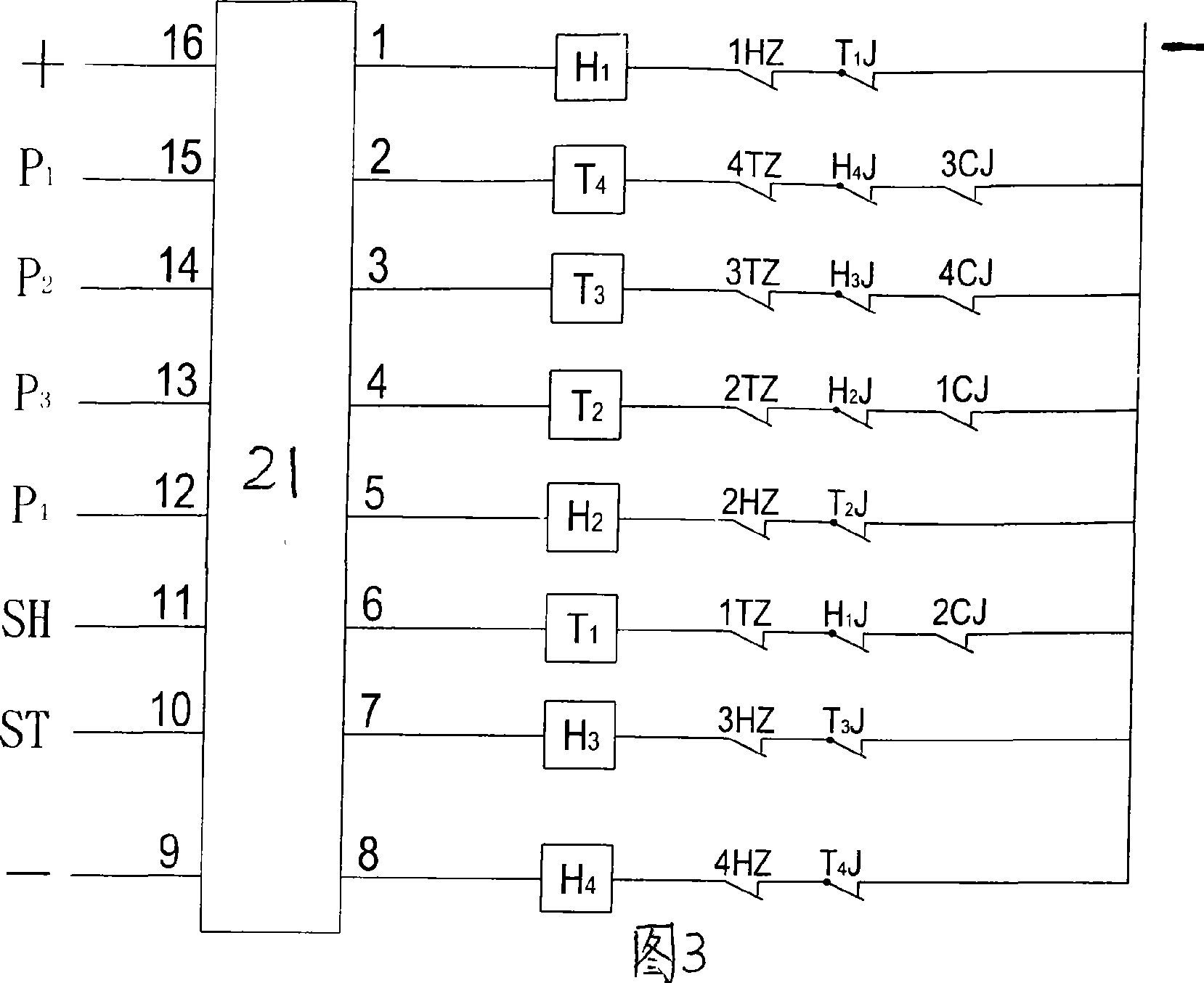

[0034]The automatic control principle and circuit principle are shown in Figure 2-6. When the line is covered with ice above 5mm, the resonator in the frost sensor vibrates and sends out a pulse-type ice-melting signal, which is transmitted to the computer automatic control device in the special switch through the sub-wire, and the computer chip melts the ice according to the program.

[0035] For example, the sub-conductor numbers of the four-split transmission line are shown in Figure 7, and the ice-melting action procedure is as follows:

[0036] (1) Confirm all sub-wire combination switches K 1 -K 4 They are all in the closed state, and start to melt the ice on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com