Underwater fixed depth releasing device

A release device and steel ball technology, applied in underwater operation equipment, transportation and packaging, ships, etc., can solve problems such as crushing of robot parts, and achieve the effects of large load bearing, convenient loading and unloading, and easy detection and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in more detail below in conjunction with accompanying drawing example:

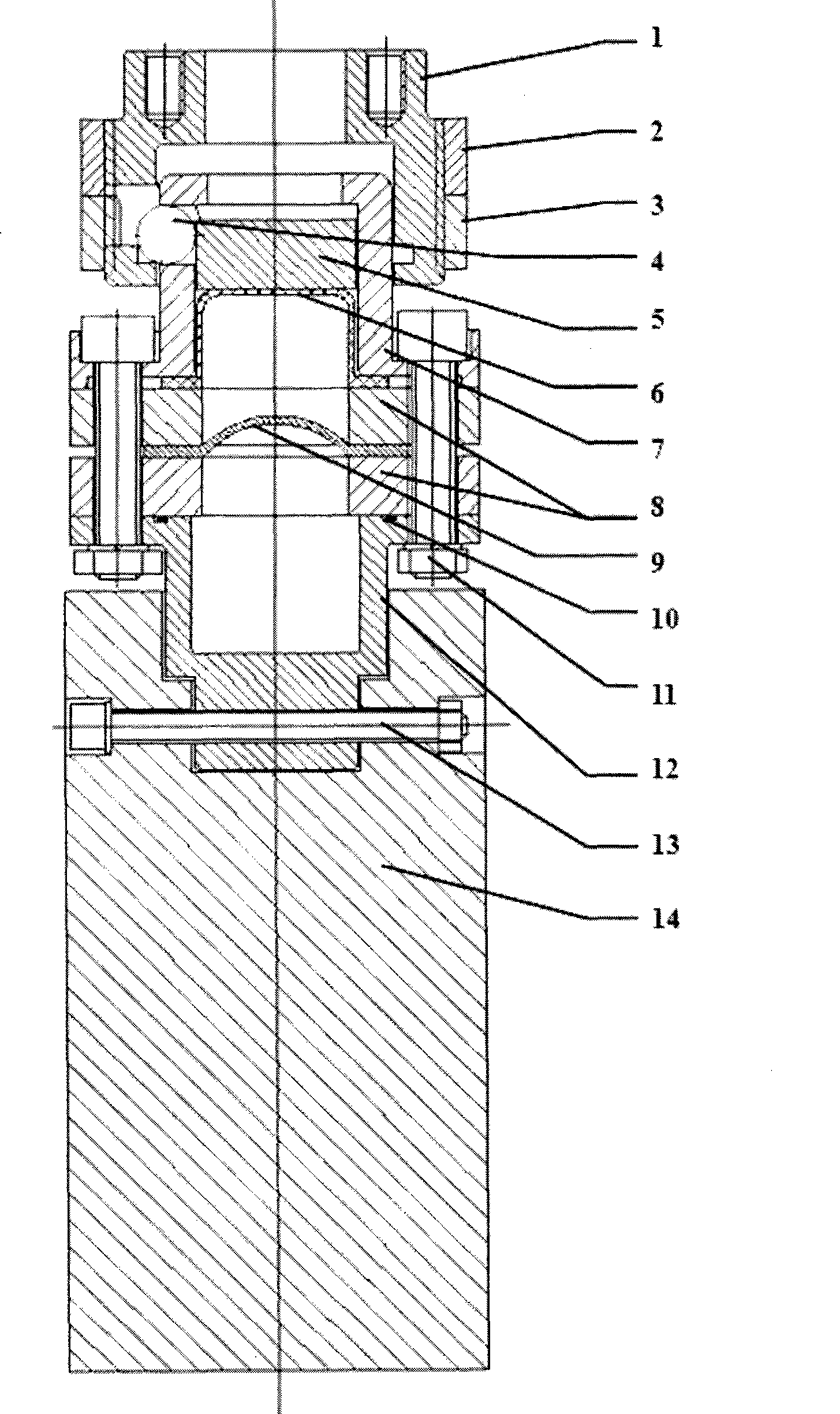

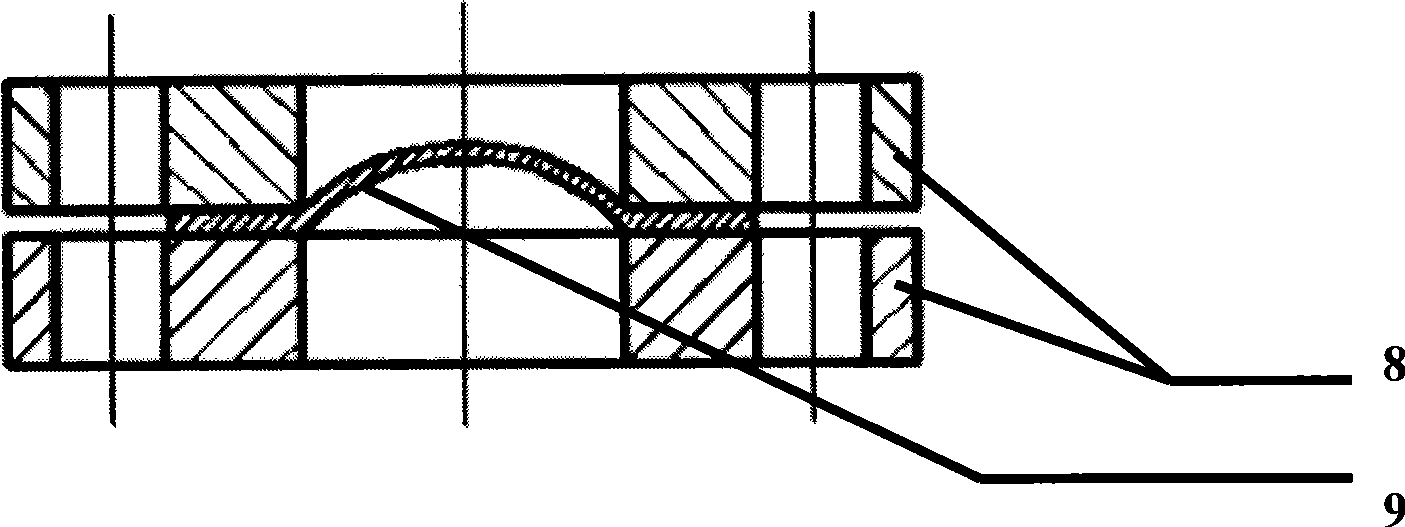

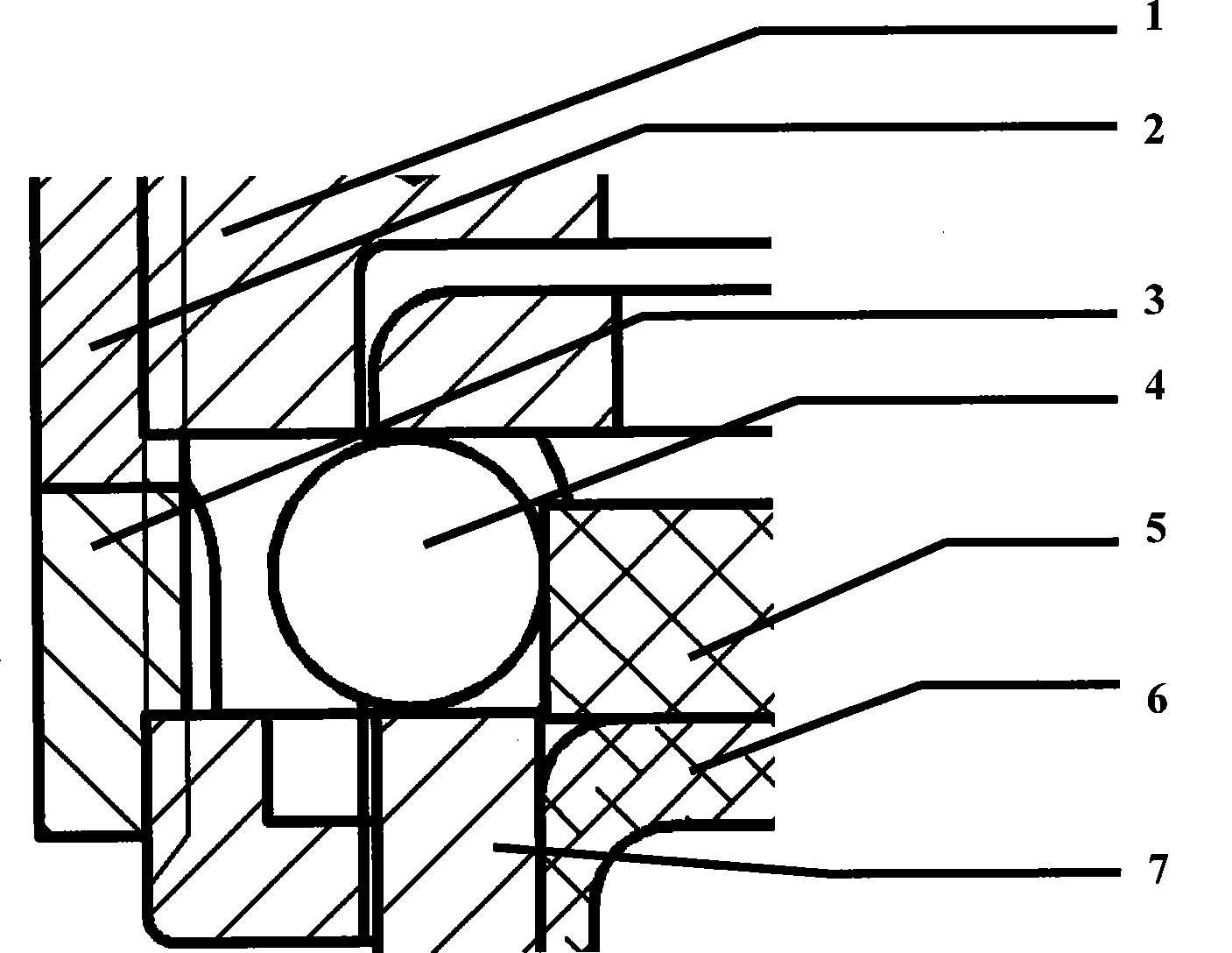

[0028] Its main components include load-bearing sleeve 1, steel ball retaining ring 1, steel ball retaining ring 2 3, steel ball 4, piston 5, leather bag 6, upper cover 7, holder 8, bursting disc 9, sealing ring 10, bolt 11, A device composed of base 12, bolt 13, ballast 14 and other components. The base 12 and the upper cover 7 are barrel-shaped with outer flanges.

[0029] Wherein the base 12 is a cavity structure, and the upper cover 7 and the wall of the load-bearing sleeve 1 each have three steel ball holes, allowing the steel ball 4 to slide therein. The diameter of the steel ball 4 is larger than the wall thickness of the upper cover 7, and the radius is smaller than the wall thickness of the upper cover 7. The load-bearing sleeve 1 has threaded holes, which are used for connecting and fixing the whole device. The load-bearing sleeve 1 has an annular groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com