Aircraft system member mounting method and apparatus based on industrial robot

An industrial robot and aircraft system technology, which is applied in the field of the installation and installation of aircraft system components based on industrial robots, can solve the problems of complex posture adjustment and assembly process, large labor load, single task, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

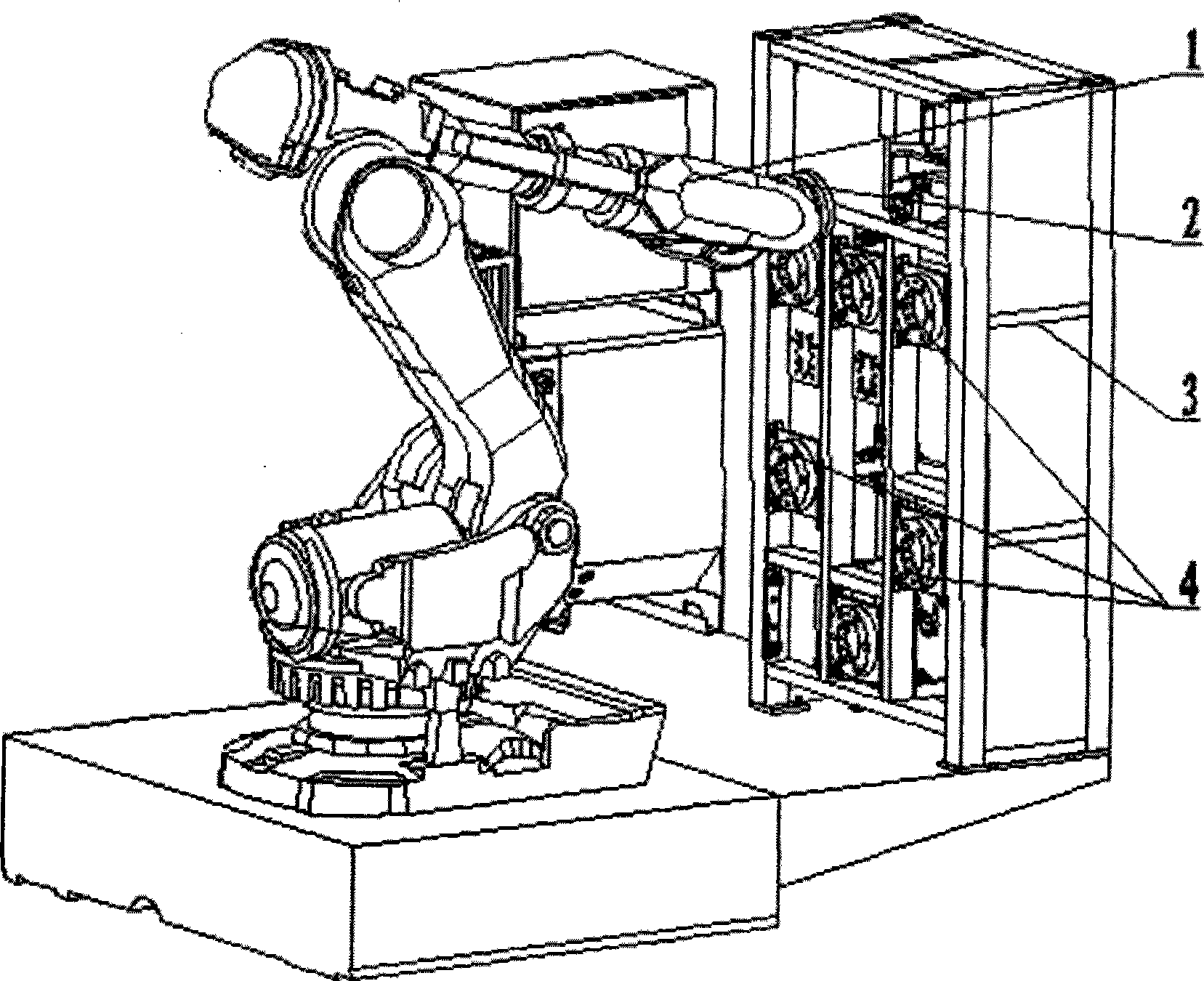

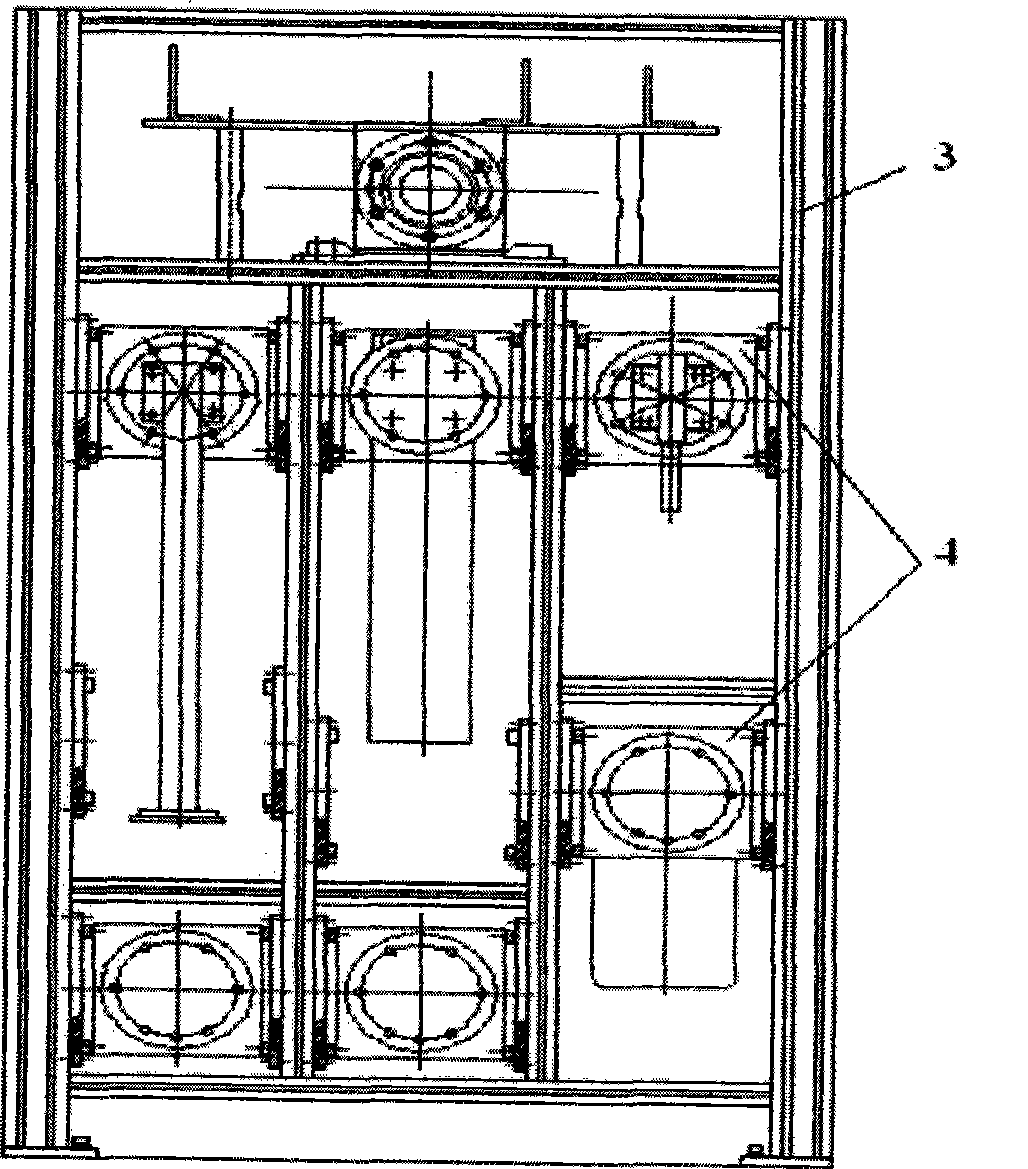

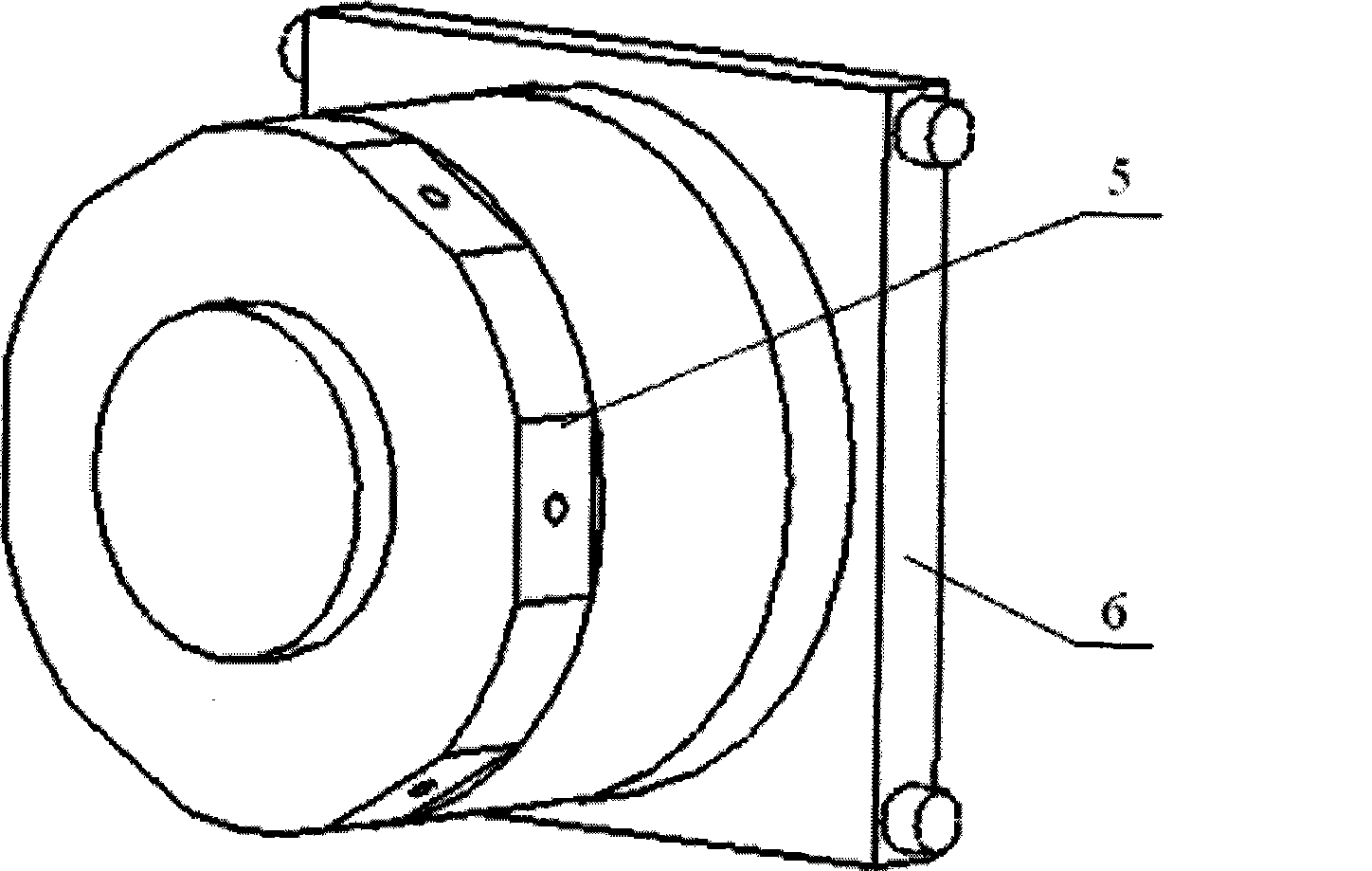

[0025] like figure 1 As shown, the aircraft system component installation device based on an industrial robot includes an industrial robot 1 , a tool quick changer 2 , a system component library 3 , and a system component template 4 .

[0026] The method for installing aircraft system components based on industrial robots uses an industrial robot 1 to automatically grab and replace the system component template 4 through the tool quick changer 2, and automatically install the system component template 4 according to the working path and target pose calibrated by the laser tracker position.

[0027] Industrial robot 1 is an ABB IRB6640 six-axis robot.

[0028] Before the actual aircraft system component auxiliary installation task, the initial motion trajectory of the robot control point TCP is generated by the offline programming syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com