Safe pure chlorine dioxide preparing apparatus and method

A chlorine dioxide and chlorine dioxide technology, which is applied in chemical engineering and process fields, can solve the problems of packaging and transportation waste, influence effect, waste of resources, etc., and achieve the effects of high production efficiency, low cost, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

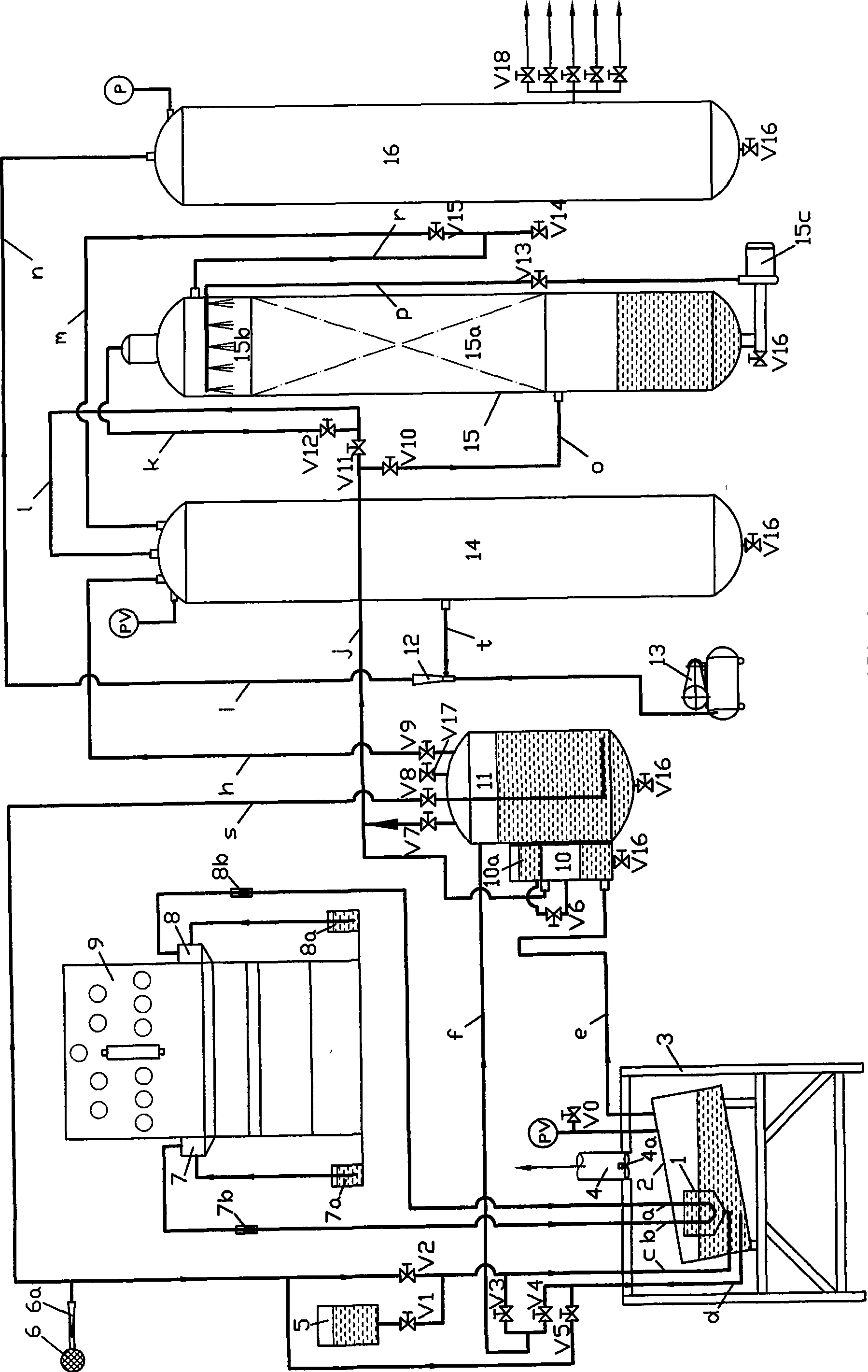

[0029] figure 1 A system schematic diagram of a pure chlorine dioxide gas preparation device is shown. The device is composed of systems such as feeding, tertiary reaction, explosion-proof isolation, gas washing conversion, vacuum suction and pressure transportation, emergency shutdown protection and operation control. The following are the introductions:

[0030] 1. Feeding system

[0031] The prepared first raw material and second raw material are respectively placed in the first material tank 7a and the second material tank 8a, and the first material pump 7 passes the first material through the first back pressure valve 7b and enters the primary reactor through the pipeline b 1. The second material pump 8 sends the second material into the primary reactor 1 through the second back pressure valve 8b through the pipeline a.

[0032] 2. Three-stage reaction system

[0033] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com